China's Refractories ›› 2020, Vol. 29 ›› Issue (3): 1-6.DOI: 10.19691/j.cnki.1004-4493.2020.03.001

• Original article • Next Articles

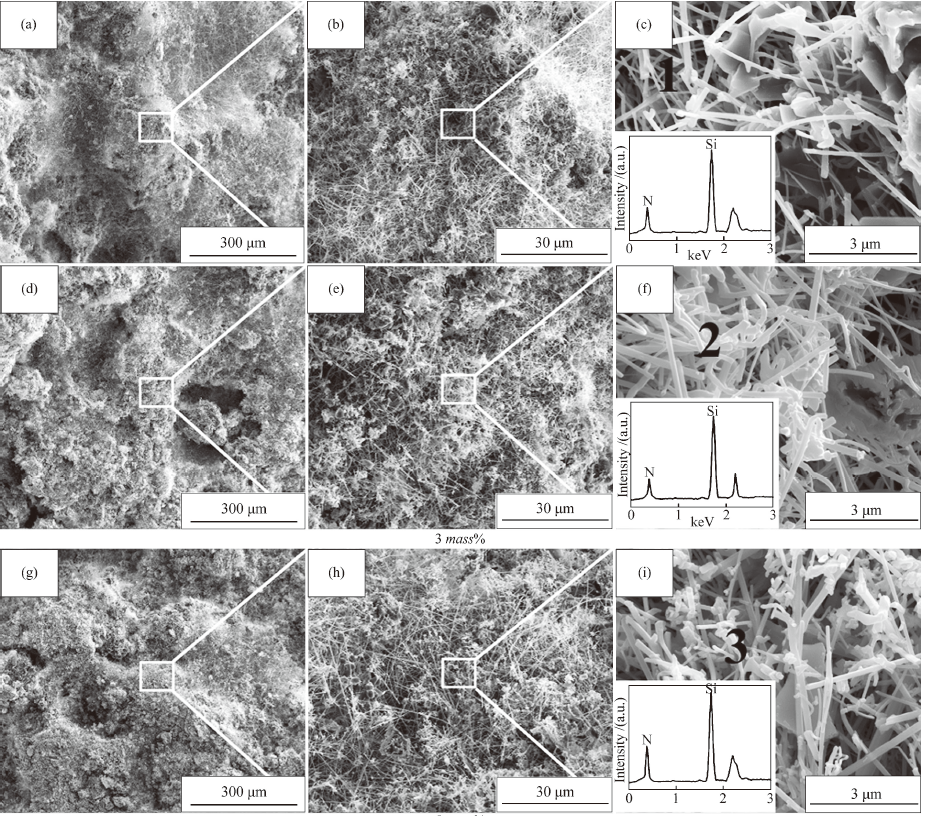

Preparation of Si3N4 Porous Ceramics via Combined Foam-gelcasting and Catalytic Nitridation with Fe Powder as Catalyst

Lei HAN1,2, Haijun ZHANG1,*( ), Shaowei ZHANG2

), Shaowei ZHANG2

- 1 The State Key Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology, Wuhan 430081, China

2 College of Engineering, Mathematics and Physical Sciences, University of Exeter, Exeter EX4 4QF, UK

-

Online:2020-09-15Published:2020-09-15 -

Contact:Haijun ZHANG -

About author:Han Lei, born in 1987 in Hennan Provence, received his bachelor’s degree from Luoyang Institute of Science and Technology in 2014, majoring in inorganic non-metal material science and engineering. Then, he graduated from the State Key Laboratory of Refractory Metallurgy, Wuhan University of Science and Technology in 2017 and 2020 respectively with a master’s degree and a doctorate, majoring in materials science and engineering. His research field is high-performance ceramics and refractories.

Cite this article

Lei HAN, Haijun ZHANG, Shaowei ZHANG. Preparation of Si3N4 Porous Ceramics via Combined Foam-gelcasting and Catalytic Nitridation with Fe Powder as Catalyst[J]. China's Refractories, 2020, 29(3): 1-6.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2020.03.001

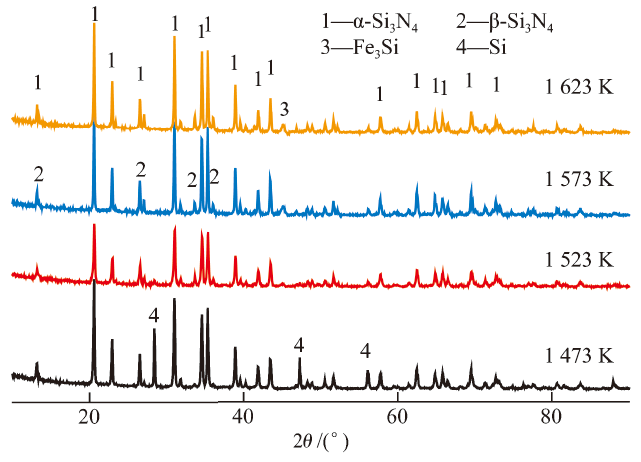

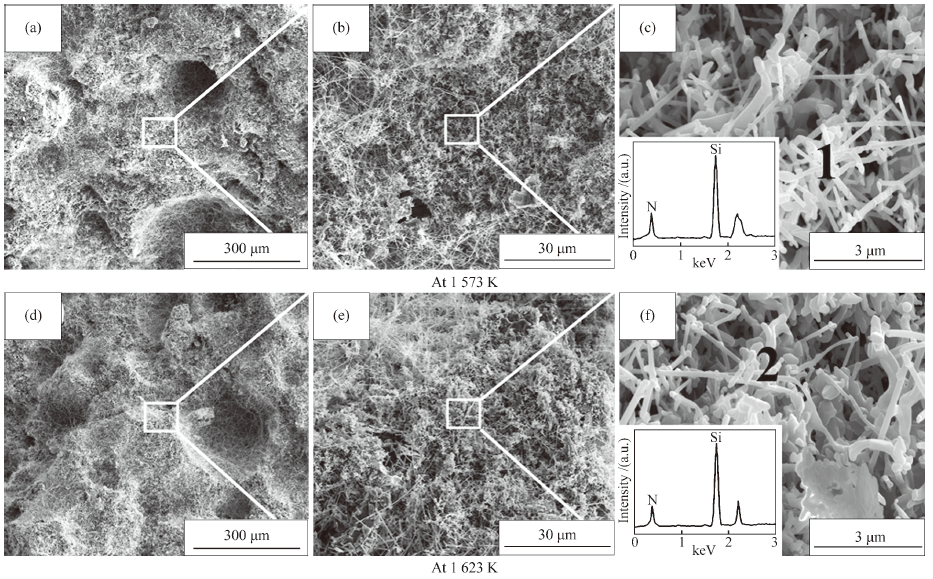

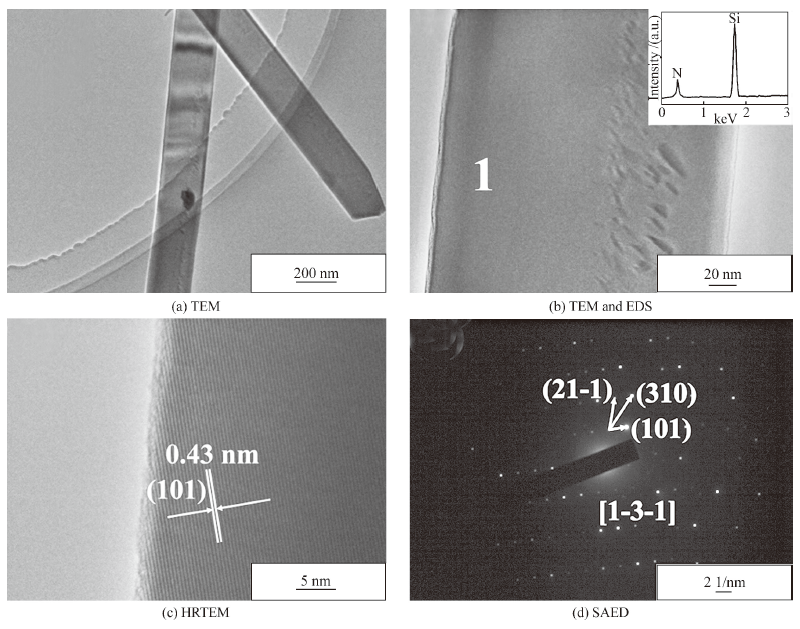

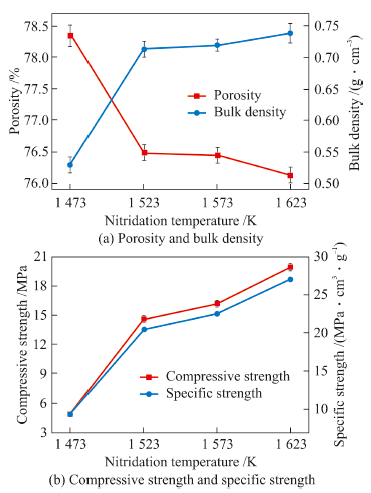

Fig. 4 Effects of nitridation temperature on porosity, bulk density, compressive strength, and specific strength of Si3N4 porous ceramics 3.2 Effect of Catalyst Addition

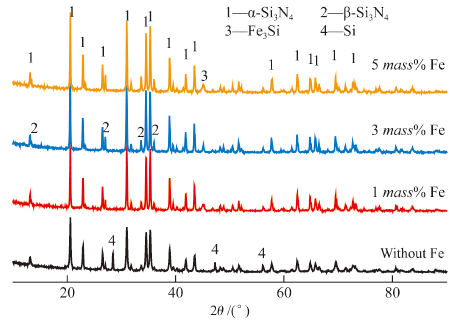

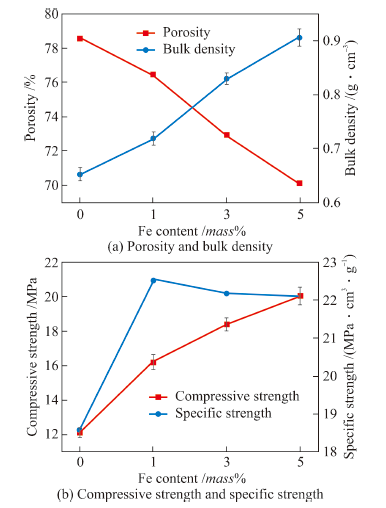

Fig. 7 Porosity, bulk density, compressive strength, and specific strength of Si3N4 porous ceramics prepared at 1 573 K for 5 h with various additions of Fe powder

| [1] |

Zhaoyun Xu, Bo Wang, Jianfeng Yang, Zhongjian Zhao. Preparation of porous Si3N4 ceramics with controlled porosity and microstructure by fibrous α-Si3N4 addition. Journal of the American Ceramic Society, 2014,97(11):3392-3395.

DOI URL |

| [2] |

Ayse Kalemtas, Gulsum Topates, Hüseyin Özcoban, Hasan Mandal, Ferhat Kara, Rolf Janssen. Mechanical characterization of highly porous β-Si3N4 ceramics fabricated via partial sintering & starch addition. Journal of the European Ceramic Society, 2013,33(9):1507-1515.

DOI URL |

| [3] |

Jianfeng Yang, Guojun Zhang, Naoki Kondo, Tatsuki Ohji, Shuzo Kanzaki. Synthesis of porous Si3N4 ceramics with rod-shaped pore structure. Journal of the American Ceramic Society, 2005,88(4):1030-1032.

DOI URL |

| [4] |

Tao Wan, Dongxu Yao, Jinwei Yin, Yongfeng Xia, Kaihui Zuo, Hanqin Liang, Yuping Zeng. A novel method for preparing Si3N4 ceramics with unidirectional oriented pores from silicon aqueous slurries. Journal of the European Ceramic Society, 2017,37(10):3285-3291.

DOI URL |

| [5] | Liuyan Yin, Xingui Zhou, Jinshan Yu, Honglei Wang, Shuang Zhao, Zheng Luo, Bei Yang. New consolidation process inspired from making steamed bread to prepare Si3N4 foams by protein foaming method. Journal of the European Ceramic Society, 2013,33(7):1387-1392. |

| [6] | Hai-Long Hu, Yu-Ping Zeng, Yong-Feng Xia, Dong-Xu Yao, Kai-Hui Zuo, Jens Günster, Jürgen G. Heinrich. Rapid fabrication of porous Si3N4/SiC ceramics via nitridation of silicon powder with ZrO2 as the catalyst. Ceramics International, 2014,40(5):7579-7582. |

| [7] | Lei Han, Junkai Wang, Faliang Li, Huifang Wang, Xiangong Deng, Haijun Zhang, Shaowei Zhang. Low-temperature preparation of Si3N4 whiskers bonded/reinforced SiC porous ceramics via foam-gelcasting combined with catalytic nitridation. Journal of the European Ceramic Society, 2018,38(4):1210-1218. |

| [8] | Zhen Wu, Luchao Sun, Peng Wan, Junning Li, Zijun Hu, Jingyang Wang. In situ foam-gelcasting fabrication and properties of highly porous γ-Y2Si2O7 ceramic with multiple pore structures. Scripta Materialia, 2015,103:6-9. |

| [9] | Lei Han, Faliang Li, Xiangong Deng, Junkai Wang, Haijun Zhang, Shaowei Zhang. Foam-gelcasting preparation, microstructure and thermal insulation performance of porous diatomite ceramics with hierarchical pore structures. Journal of the European Ceramic Society, 2017,37(7):2717-2725. |

| [10] | Yajun Gu, Lilin Lu, Haijun Zhang, Yingnan Cao, Faliang Li, Shaowei Zhang. Nitridation of silicon powders catalyzed by cobalt nanoparticles. Journal of the American Ceramic Society, 2015,98(6):1762-1768. |

| [11] | Varong Pavarajarn, Shoichi Kimura. Catalytic effects of metals on direct nitridation of silicon. Journal of the American Ceramic Society, 2001,84(8):1669-1674. |

| [12] | Juntong Huang, Zhaohui Huang, Shaowei Zhang, Minghao Fang, Yan’gai Liu. Si3N4-SiCp composites reinforced by in situ Co-catalyzed generated Si3N4 nanofibers. Journal of Nanomaterials, 2014(10):1-6. |

| [13] | Hailong Hu, Dongxu Yao, Yongfeng Xia, Kaihui Zuo, Yuping Zeng. Porous Si3N4/SiC ceramics prepared via nitridation of Si powder with SiC addition. International Journal of Applied Ceramic Technology, 2013,11(5):845-850. |

| [14] | Xiangong Deng, Songlin Ran, Lei Han, Haijun Zhang, Shengtao Ge, Shaowei Zhang. Foam-gelcasting preparation of high-strength self-reinforced porous mullite ceramics. Journal of the European Ceramic Society, 2017,37(13):4059-4066. |

| [15] | Lei Yuan, Beiyue Ma, Qiang Zhu, Zijing Wang, Guangqiang Li, Jingkun Yu. Preparation and properties of MgAl2O4 based ceramics reinforced with rod-like microcrystallines by co-doping Sm2O3 and La2O3. Ceramics International, 2017,43(18):16258-16263. |

| [1] | ZHANG Keke, QIN Feng, YAN Miaoxin, LIU Shijie, LI Xuhao, GUO Yusen, WANG Li, YIN Chaofan, DONG Binbin. Progress in Preparation Technology of Porous Ceramics for High Temperature Dust Filtration [J]. China's Refractories, 2023, 32(4): 42-51. |

| [2] | CHEN Yang, DENG Chengji, DING Jun, YU Chao, LOU Xiaoming. Effect of Ferric Nitrate Loading Mode on Properties of Si3N4 Composite MgO-C Refractories Prepared by Nitridation [J]. China's Refractories, 2023, 32(3): 6-9. |

| [3] | GAO Jinxing, XU Lingling, LI Liya, MU Jinghua, LI Xiaokai, XU Enxia, GUO Donghui, MENG Dekang, ZHOU Gaofeng, CHEN Shoujie. Effect of Y2O3 Addition on Preparation and Properties of β-SiAlON Reticular Porous Ceramic Filters [J]. China's Refractories, 2022, 31(4): 28-33. |

| [4] | YAN Mingwei, LIU Kaiqi, ZHANG Jiayu, SUN Guangchao, LI Xiang, SI Kaikai. Research Progress on Thermal Shock Behavior of Porous Ceramics [J]. China's Refractories, 2022, 31(1): 24-29. |

| [5] | WANG Tao, WANG Bo, HOU Baoqiang, SHI Zhongqi, YANG Jun, XIA Hongyan, WANG Jiping, WANG Hongjie, YANG Jianfeng. Preparation and Application Progress of Porous Alumina [J]. China's Refractories, 2020, 29(4): 10-18. |

| [6] | SU Chang, MA Beiyue, REN Xinming, LIU Guoqiang, ZHU Qiang. Effect of Starch Addition on Properties of Corundum-mullite Porous Ceramics [J]. China's Refractories, 2020, 29(4): 19-22. |

| [7] | LI Fei, LIU Jixuan, ZHANG Guojun. Porous Ultra-high Temperature Ceramics for Ultra-high Temperature Thermal Protection System [J]. China's Refractories, 2020, 29(4): 23-28. |

| [8] | ZHANG Qi, YUAN Bo, WANG Gang, HAN Jianshen, ZHAO Xin. Effect of Nitriding Process on Phase and Microstructure of Silicon Nitride Fibers Prepared by Direct Nitriding Method [J]. China's Refractories, 2020, 29(4): 40-45. |

| [9] | LAO Dong, JIA Wenbao, WANG Yufan, CHEN Ruoyu, LI Shujing, HEI Daqian, WANG Zhonghua, DING Yue, ZHANG Wenhao, LIU Meiqi. Fabrication and Properties of Alumina-based Reticulated Porous Ceramics [J]. China's Refractories, 2020, 29(2): 31-36. |

| [10] | ZHENG Han, LI Wei, DU Jiaolong, LI Hongxia, LIU Guoqi, CHEN Zihao, CHEN Yongqiang. Preparation and Properties of Si2N2O Ceramics for Microwave Sintering Furnaces [J]. China's Refractories, 2020, 29(2): 42-46. |

| [11] | WANG Gang, ZHANG Qi, HAN Jianshen, YUAN Bo, LI Hongxia. Preparation and Properties of Calcium Hexaaluminate Porous Ceramics [J]. China's Refractories, 2020, 29(1): 15-19. |

| [12] | CAO Huiyan, HUANG Zhigang, ZHANG Xinhua, LIU Zhen. Research on Steam Oxidation Resistance of Si3N4-bonded SiC Refractories [J]. China's Refractories, 2020, 29(1): 44-47. |

| [13] | ZHANG Yaran, MA Beiyue, YU Jingyu, SU Chang, REN Xinming, QIAN Fan, LIU Guoqi, LI Hongxia, YU Jingkun. Preparation of SiC Porous Ceramics by Crystalline Silicon Cutting Waste [J]. , 2018, 27(4): 46-50. |

| [14] | REN Xinming, MA Beiyue, SU Chang, YU Jingyu, ZHANG Yaran. Effect of Main Material Ratio on Properties of SiC-Al2O3 Porous Ceramics via Polymeric Replication Method [J]. , 2018, 27(3): 44-47. |

| [15] | MA Xiaochen,YINHongfeng,ZHANGJunzhan, REN Yun. Synthesis of Si3N4 Powder Using Sawdust as Carbon Source [J]. , 2016, 25(2): 29-34. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||