China's Refractories ›› 2022, Vol. 31 ›› Issue (1): 24-29.DOI: 10.19691/j.cnki.1004-4493.2022.01.004

Previous Articles Next Articles

Research Progress on Thermal Shock Behavior of Porous Ceramics

YAN Mingwei1, LIU Kaiqi1,2,*( ), ZHANG Jiayu1,2, SUN Guangchao1,2, LI Xiang1,2, SI Kaikai1,2

), ZHANG Jiayu1,2, SUN Guangchao1,2, LI Xiang1,2, SI Kaikai1,2

- 1 State Key Laboratory of Multiphase Complex Systems, Institute of Process Engineering,Chinese Academy of Sciences, Beijing 100019, China

2 University of Chinese Academy of Sciences, Beijing 100049, China

-

Online:2022-03-15Published:2022-04-02 -

Contact:LIU Kaiqi -

About author:YAN Mingwei works as a postdoctoral fellow in Institute of Process Engineering, Chinese Academy of Sciences now. In 2020, he received his Ph.D degree of material science and engineering from University of Science and Technology Beijing. His research interests include ceramic materials synthesis, porous ceramics, metal-oxide refractories, oxide refractories and non-oxide refractories. He has published more than thirty articles and applied for some patents so far.

Cite this article

YAN Mingwei, LIU Kaiqi, ZHANG Jiayu, SUN Guangchao, LI Xiang, SI Kaikai. Research Progress on Thermal Shock Behavior of Porous Ceramics[J]. China's Refractories, 2022, 31(1): 24-29.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2022.01.004

| Index | LP-Si3N4 | MP-Si3N4 | HP-Si3N4 |

|---|---|---|---|

| Porosity /% | 16.8 | 23.8 | 37.1 |

| Fracture strength /MPa | 476 | 408 | 135 |

| Young’s modulus /GPa | 230 | 216 | 149 |

| Fracture toughness /(MPa ·m -1/2) | 4.20 | 5.64 | 3.05 |

| Poisson’s ratio | 0.25 | 0.24 | 0.23 |

| Thermal expansion coefficient /(×106/℃) | 4.72 | 4.66 | 4.12 |

Table 1 Properties of porous LP-Si3N4, MP-Si3N4 and HP-Si3N4 ceramics[20]

| Index | LP-Si3N4 | MP-Si3N4 | HP-Si3N4 |

|---|---|---|---|

| Porosity /% | 16.8 | 23.8 | 37.1 |

| Fracture strength /MPa | 476 | 408 | 135 |

| Young’s modulus /GPa | 230 | 216 | 149 |

| Fracture toughness /(MPa ·m -1/2) | 4.20 | 5.64 | 3.05 |

| Poisson’s ratio | 0.25 | 0.24 | 0.23 |

| Thermal expansion coefficient /(×106/℃) | 4.72 | 4.66 | 4.12 |

| Index | LP-Si3N4 | MP-Si3N4 | HP-Si3N4 |

|---|---|---|---|

| R | 329 | 308 | 170 |

| R'''' | 97 | 237 | 628 |

Table 2 Calculated values of R and R'''' for porous LP-Si3N4, MP-Si3N4 and HP-Si3N4 ceramics[20] /℃

| Index | LP-Si3N4 | MP-Si3N4 | HP-Si3N4 |

|---|---|---|---|

| R | 329 | 308 | 170 |

| R'''' | 97 | 237 | 628 |

| [1] | Rafael Kenji Nishihora, Priscila Lemes Rachadel, Mara Gabriela Novy Quadri, Dachamir Hotza. Manufacturing porous ceramic materials by tape casting: a review. Journal of the European Ceramic Society, 2018,38(4):988-1001. |

| [2] | W. D. Kingery. Factors affecting thermal stress resistance of ceramic materials. Journal of the American Ceramic Society, 1955,38(1):3-15. |

| [3] | E H. Kerner. The elastic and thermo-elastic properties of composite media. Proceedings of the Physical Society Section B, 1956,69(8):808-813. |

| [4] | D. P. H. Hasselman. Elastic energy at fracture and surface energy as design criteria for thermal shock. Journal of the American Ceramic Society, 1963,46(11):535-540. |

| [5] | Didericus Hasselman. Thermal stress resistance parameters of brittle refractory ceramics: a compendium. American Ceramic Society Bulletin, 1970,49(12):1033-1037. |

| [6] | D. P. H. Hasselman. Unified theory of thermal shock facture initiation and crack propagation in brittle ceramics. Journal of the American Ceramic Society, 1969,52(11):600-604. |

| [7] | W. David Kingery, H. K. Bowen, Donald R. Uhlmann. Introduction to Ceramics, 2nd Edition. Japan: John Wiley & Sons, 1976: 449-468. |

| [8] | Songhe Meng, Guoqian Liu, Yue Guo, Xianghong Xu, Fan Song. Mechanisms of thermal shock failure for ultra-high temperature ceramic. Materials & Design, 2009,30(6):2108-2112. |

| [9] | B. Legendre, F. Osterstock. On the quantification of quenching transient thermal stresses in brittle solids using Vickers indentations. Journal of Materials Science Letters, 1997,16(7):584-587. |

| [10] | M. Collin, D. Rowcliffe. Analysis and prediction of thermal shock in brittle materials. Acta Materialia, 2000,48(8):1655-1665. |

| [11] | Zeping Zhang, Yingfeng Shao, Fan Song. Characteristics of crack patterns controlling the retained strength of ceramics after thermal shock. Frontiers of Materials Science in China, 2010,4(3):251-254. |

| [12] | Kaixuan Gui, Ping Hu, Wenhu Hong, Xinghong Zhang, Shun Dong. Microstructure, mechanical properties and thermal shock resistance of ZrB2-SiC-Cf composite with inhibited degradation of carbon fibers. Journal of Alloys and Compounds, 2017,706:16-23. |

| [13] | Standard test method for determination of thermal shock resistance for advanced ceramics by water quenching, ASTM C1525-2004, 2013. |

| [14] | Zhu Xinwen, Jiang Dongliang, Tan Shouhong. Processing, properties and application of porous ceramics: (II) strcuture, properties and application of porous ceramics. Journal of Ceramics (in Chinese), 2003,24(2):85-91. |

| [15] | Han Yao. Structural design, fabrication and properties of anorthite based porous ceramics [Dissertation, (in Chinese)]. Beijing: Beijing Jiaotong University, 2014, 1-20. |

| [16] | Chi Jing, Li Min, Wang Shufeng, Wu Jie. Effects of Ti-C contents on the pore structures and mechanical properties of porous TiC/FeAl composites. Acta Materiae Compositae Sinica (in Chinese), 2018,35(9):2503-2511. |

| [17] | Liu Peisheng. Basic analysis to classical model for foamed metals. Nonferrous Metals (in Chinese), 2005,57(2):55-57. |

| [18] | R. W. Rice. Comparison of stress concentration versus minimum solid area based mechanical property-porosity relations. Journal of Materials Science, 1993,28(8):2187-2190. |

| [19] | Wang Chang'an, Lang Ying, Hu Liangfa, Dong Yanhao, Zhou Jun. Research progress on lightweight and high strength heat-insulating porous ceramics. Journal of Ceramics (in Chinese), 2017,38(3):287-296. |

| [20] | J. H. She, J. F. Yang, T. Ohji. Thermal shock resistance of porous silicon nitride ceramics. Journal of Materials Science Letters, 2003,22(5):331-333. |

| [21] | Bingbin Dong, Gang Wang, Bo Yuan, Jianshen Han. Fabrication and properties of porous alumina ceramics with three different pore sizes. Journal of Porous Materials, 2017,24(3):805-811. |

| [22] | Dean-Mo Liu. Influence of porosity and pore size on the compressive strength of porous hydroxyapatite ceramic. Ceramics International, 1997,23(2):135-139. |

| [23] | A. A. Griffith. The phenomena of rupture and flow in solids. Philosophical Transactions of the Royal Society of London, 1921,221:163-198. |

| [24] | Liangfa Hu, Rogelio Benitez, Sandip Basu, Ibrahim Karaman, Miladin Radovic. Processing and characterization of porous Ti2AlC with controlled porosity and pore size. Acta Materialia, 2012,60(18):6266-6277. |

| [25] | N. J. Petch. The cleavage strength of polycrystals. Journal of the Iron and Steel Institute, 1953,174(1):25-28. |

| [26] | Xinxin Jin, Limin Dong, Huanyan Xu, Lizhu Liu, Ning Li, Xinghong Zhang, Jiecai Han. Effects of porosity and pore size on mechanical and thermal properties as well as thermal shock fracture resistance of porous ZrB2-SiC ceramics. Ceramics International, 2016,42(7):9051-9057. |

| [27] | Dan Tian, Chan-Juan Zhou, Ji-Huan He. Hall-Petch effect and inverse Hall-Petch effect: A fractal unification. Fractals, 2018,26(6):183-185. |

| [28] | Lu Jun, Zeng Xiaoqin, Ding Wenjiang. The hall-petch relationship. Light Metal (in Chinese), 2008(8):59-64. |

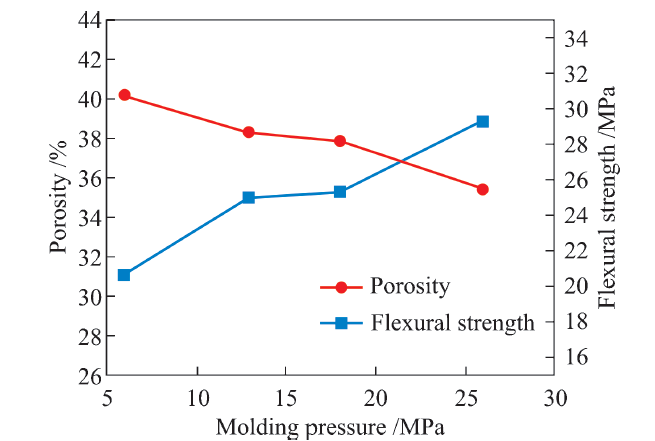

| [29] | Junfeng Li, Hong Lin, Xin Li. Factors that influence the flexural strength of SiC-based porous ceramics used for hot gas filter support. Journal of the European Ceramic Society, 2011,31(5):825-831. |

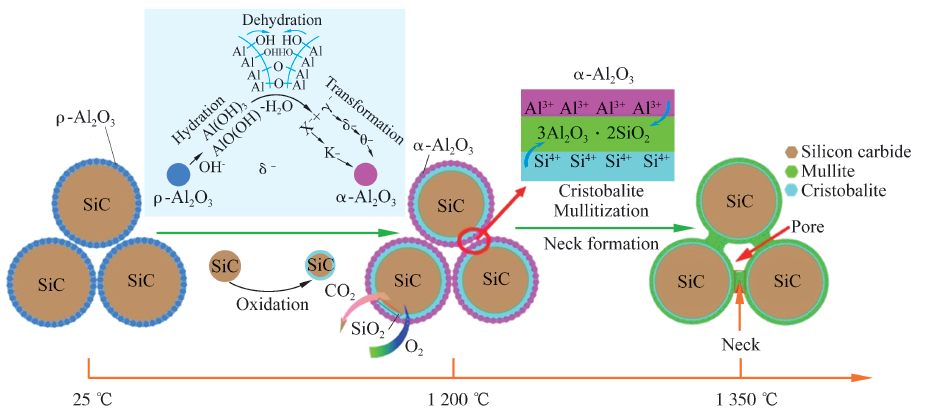

| [30] | Zhiyong Luo, Kaiqi Liu, Wei Han, Wenqing Ao, Yunfa Chen. Effect of ρ-Al2O3 addition on the properties of in situ reaction-bonded porous SiC membrane support. The Chinese Journal of Process Engineering (in Chinese), 2019(2):407-412. |

| [31] | Zhiyong Luo, Wei Han, Xiaojie Yu, Wenqing Ao, Kaiqi Liu. In-situ reaction bonding to obtain porous in-situ reaction bonding to obtain porous SiC membrane supports with excellent mechanical and permeable performance. Ceramics International, 2019,45(7):9007-9016. |

| [1] | Yunpeng ZHOU, Wang FENG, Shankha CHATTERJEE, Andus BUHR, Sebastian KLAUS. Study on Chrome-free Purging Plugs for Steel Ladles [J]. China's Refractories, 2024, 33(2): 41-47. |

| [2] | ZHANG Keke, QIN Feng, YAN Miaoxin, LIU Shijie, LI Xuhao, GUO Yusen, WANG Li, YIN Chaofan, DONG Binbin. Progress in Preparation Technology of Porous Ceramics for High Temperature Dust Filtration [J]. China's Refractories, 2023, 32(4): 42-51. |

| [3] | GUO Peng, CHEN Lu, YU Tongshu, ZHANG Hui, WANG Dongdong. Effect of Zirconia Corundum Addition on Properties of Chrome Corundum Castables [J]. China's Refractories, 2023, 32(2): 41-44. |

| [4] | LI Yanjing, SUN Jialin, LI Yong, KANG Jian, MA Shulong, MA Fei, ZHANG Jili. Influence of Flotation Magnesia Particles and Al2O3 Fines on Properties of Periclase-spinel Bricks [J]. China's Refractories, 2022, 31(4): 12-15. |

| [5] | GAO Jinxing, XU Lingling, LI Liya, MU Jinghua, LI Xiaokai, XU Enxia, GUO Donghui, MENG Dekang, ZHOU Gaofeng, CHEN Shoujie. Effect of Y2O3 Addition on Preparation and Properties of β-SiAlON Reticular Porous Ceramic Filters [J]. China's Refractories, 2022, 31(4): 28-33. |

| [6] | LIU Zhenglong, DENG Chengji, YU Chao, DING Jun, ZHU Hongxi. Effect of C@SiC Composite Powder Addition on Properties of Al2O3-SiC-C Castables for Iron Trough [J]. China's Refractories, 2022, 31(4): 39-44. |

| [7] | HAO Xian, LIU Guoqi, LI Zhixing, XU Chaojie, ZHANG Jianwei, LI Yong, LI Hongyu, LI Hongxia, FU Baoquan. Effect of Al-Si Alloy Addition on Properties of Fused Spinel Carbon Materials [J]. China's Refractories, 2022, 31(4): 45-52. |

| [8] | ZHU Shaojun. Damage Mechanism and Countermeasures of Al2O3-SiC-C Refractories Under Extreme Conditions [J]. China's Refractories, 2022, 31(2): 7-11. |

| [9] | HAN Xiaoyuan, SHI Kai, XIA Yi, WANG Peixun, LIU Yang, SHANG Jianzhao. Effects of Three Silicon-based Raw Materials on Properties and Microstructure of MgO-Al-C Materials [J]. China's Refractories, 2021, 30(4): 30-35. |

| [10] | LIU Guoqi, LI Hongxia, YANG Wengang, QIAN Fan, YU Jianbin, MA Weikui. Design of Composite Ladle Shroud for Improving Thermal Shock Resistance [J]. China's Refractories, 2021, 30(1): 31-34. |

| [11] | WANG Tao, WANG Bo, HOU Baoqiang, SHI Zhongqi, YANG Jun, XIA Hongyan, WANG Jiping, WANG Hongjie, YANG Jianfeng. Preparation and Application Progress of Porous Alumina [J]. China's Refractories, 2020, 29(4): 10-18. |

| [12] | SU Chang, MA Beiyue, REN Xinming, LIU Guoqiang, ZHU Qiang. Effect of Starch Addition on Properties of Corundum-mullite Porous Ceramics [J]. China's Refractories, 2020, 29(4): 19-22. |

| [13] | LI Fei, LIU Jixuan, ZHANG Guojun. Porous Ultra-high Temperature Ceramics for Ultra-high Temperature Thermal Protection System [J]. China's Refractories, 2020, 29(4): 23-28. |

| [14] | GUO Hongxiang, SUN Xiaogai, JIA Quanli, LI Xueyan, LIU Xinhong. Effect of Calcium Chloride Addition on Properties of Corundum Spinel Castable [J]. China's Refractories, 2020, 29(4): 46-49. |

| [15] | Lei HAN, Haijun ZHANG, Shaowei ZHANG. Preparation of Si3N4 Porous Ceramics via Combined Foam-gelcasting and Catalytic Nitridation with Fe Powder as Catalyst [J]. China's Refractories, 2020, 29(3): 1-6. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||