China's Refractories ›› 2020, Vol. 29 ›› Issue (4): 10-18.DOI: 10.19691/j.cnki.1004-4493.2020.04.003

• Original article • Previous Articles Next Articles

Preparation and Application Progress of Porous Alumina

WANG Tao, WANG Bo, HOU Baoqiang, SHI Zhongqi, YANG Jun, XIA Hongyan, WANG Jiping, WANG Hongjie, YANG Jianfeng*( )

)

- State Key Laboratory for Mechanical Behavior of Materials, Xi’an Jiaotong University, Xi’an 710049, China

-

Online:2020-12-15Published:2020-12-15 -

Contact:YANG Jianfeng -

About author:Wang Tao, born in 1995, gained his bachelor’s degree from Xi’an Jiaotong University in 2018, majored in inorganic non-metallic materials. Currently, he is studying for his master’s degree in inorganic non-metallic at the State Key Laboratory for Mechanical Behavior of Materials in Xi’an Jiaotong University. His main research direction is the preparation of porous alumina ceramics.

Cite this article

WANG Tao, WANG Bo, HOU Baoqiang, SHI Zhongqi, YANG Jun, XIA Hongyan, WANG Jiping, WANG Hongjie, YANG Jianfeng. Preparation and Application Progress of Porous Alumina[J]. China's Refractories, 2020, 29(4): 10-18.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2020.04.003

| [1] |

T. Ohji, M. Fukushima. Macro-porous ceramics: processing and properties. International Materials Reviews, 2012, 57(2): 115-131.

DOI URL |

| [2] |

Manabu Fukushima, Masayuki Nakata, You Zhou, Tatsuki Ohji, Yu-ichi Yoshizawa. Fabrication and properties of ultra-highly porous silicon carbide by the gelation-freezing method. Journal of the European Ceramic Society, 2010, 30(14): 2889-2896.

DOI URL |

| [3] |

Jung-Hye Eom, Young-Wook Kim. Effect of template size on microstructure and strength of porous silicon carbide ceramics. Journal of the Ceramic Society of Japan, 2008, 116: 1159-1163.

DOI URL |

| [4] |

Yong-Jae Jin, Young-Wook Kim. Low temperature processing of highly porous silicon carbide ceramics with improved flexural strength. Journal of Materials Science, 2010, 45(1): 282-285.

DOI URL |

| [5] | Jung-Hye Eom, Young-Wook Kim, Santosh Raju. Processing and properties of macroporous silicon carbide ceramics: A review. Journal of Asian Ceramic Societies, 2013, 1(3): 220-242. |

| [6] | Byung-Ho Yoon, Eun-Jung Lee, Hyoun-Ee Kim, Young-Hag Koh. Highly aligned porous silicon carbide ceramics by freezing polycarbosilane/camphene solution. Journal of the American Ceramic Society, 2007, 90(6): 1753-1759. |

| [7] | M. A. Gafur, M. Nasrul Haque. Effect of particle size and percentage of sawdust on the properties of light weight insulating bricks. Transactions of the Indian Ceramic Society, 1993, 52(5): 163-166. |

| [8] | Ajay Kumar, Kalyani Mohanta, Devendra Kumar, Om Parkash. Low-cost porous alumina with tailored gas permeability and mechanical properties prepared using rice husk and sucrose for filter applications. Microporous & Mesoporous Materials, 2015, 213: 48-58. |

| [9] | Feng Yi, Wang Kun, Yao Jianfeng, Paul A. Webley, Smart Simon, Wang Huanting. Effect of the addition of polyvinylpyrrolidone as a pore-former on microstructure and mechanical strength of porous alumina ceramics. Ceramics International, 2013, 39(7): 7551-7556. |

| [10] | Dong Guoxiang, Qi Hong, Xu Nanping. Effect of activated carbon doping on structure and property of porous alumina support. Journal of the Chinese Ceramic Society (in Chinese), 2012, 40(6): 844-850. |

| [11] | Jingjing Liu, Yuanbing Li, Yawei Li, Shaobai Sang, Shujing Li. Effects of pore structure on thermal conductivity and strength of alumina porous ceramics using carbon black as pore-forming agent. Ceramics International, 2016, 42(7): 8221-8228. |

| [12] | E. Gregorová, W. Pabst. Process control and optimized pre-paration of porous alumina ceramics by starch consolidation casting. Journal of the European Ceramic Society, 2011, 31(12): 2073-2081. |

| [13] | R. M. Khattab, M. M. S. Wahsh, N. M. Khalil. Preparation and characterization of porous alumina ceramics through starch consolidation casting technique. Ceramics International, 2012, 38(6): 4723-4728. |

| [14] | T. T. Dele-Afolabi, M. A. Azmah Hanim, M. Norkhairunnisa, S. Sobri, R. Calin. Research trend in the development of macroporous ceramic components by pore forming additives from natural organic matters: A short review. Ceramics International, 2016, 43(2): 1633-1649. |

| [15] | Liu Jingjing, Ren Bo, Lu Yuju, Xi Xiaoqing, Li Yajie, Liu Kele, Yang Jinlong, Huang Yong. Novel design of elongated mullite reinforced highly porous alumina ceramics using carbonized rice husk as pore-forming agent. Ceramics International, 2019, 45(11): 13964-13970. |

| [16] | Pia Giorgio, Casnedi Ludovica, Ionta Matteo, Sanna Ulrico. On the elastic deformation properties of porous ceramic materials obtained by pore-forming agent method. Ceramics International, 2015, 41(9): 11097-11105. |

| [17] | Liu Jingjing, Huo Wenlong, Ren Bo, Gan Ke, Lu Yuju, Zhang Xiaoyan, Tang Xinyue, Yang Jinlong. A novel approach to fabricate porous alumina ceramics with excellent properties via pore-forming agent combined with sol impregnation technique. Ceramics International, 2018, 44(14): 16751-16757. |

| [18] | Xu Xingxing, Qi Fei, Wang Xiuhui, Wu Jiamin, Huang Yong, Yang Jinlong. Preparation and properties of porous ceramics by coated Al2O3 hollow sphere. Journal of the Chinese Ceramic Society (in Chinese), 2014, 42(9): 1134-1139. |

| [19] | O. Omatete, M. Janney, R. Strehlow. Gel casting: A new ceramic forming process. American Ceramic Society Bulletin, 1991, 70(10): 1641-1649. |

| [20] | Wang Xiaofeng, Wang Richu, Peng Chaoqun, Li Tingting, Luo Yulin, Wang Chao, Liu Bing. Research and development of gel-casting molding technology. Chinese Journal of Nonferrous Metals (in Chinese), 2010, 20(3): 496-509. |

| [21] | Jinlong Yang, Juanli Yu, Yong Huang. Recent developments in gel-casting of ceramics. Journal of the European Ceramic Society, 2011, 31(14): 2569-2591. |

| [22] | S. Blackburn. New processes or old: Complex shape processing of advanced ceramics. Advances in Applied Ceramics, 2005, 104(3): 97-102. |

| [23] | Wu Jia-Min, Zhang Xiao-Yan, Yang Jin-Long. Novel porous Si3N4 ceramic prepared by aqueous gel casting using Si3N4 poly-hollow micro-spheres as pore-forming agent. Journal of the European Ceramic Society, 2014, 34(5): 1089-1096. |

| [24] | A. A. NajafzadehKhoee, A. Habibolahzadeh,, F. Qods, H. Baharvandi. Fabrication of tungsten carbide foam through gel-casting process using nontoxic sodium alginate. International Journal of Refractory Metals & Hard Materials, 2014, 43: 115-120. |

| [25] | Xie Yuzhou, Peng Chaoqun, Wang Xiaofeng, Wang Richu, Luo Feng. Porous alumina ceramic prepared by HEMA-TBA gel-casting system. Journal of Inorganic Materials (in Chinese), 2017, 32(7): 731-738. |

| [26] | Wang Xiaofeng, Xie Yuzhou, Peng Chaoqun, Wang Richu, Zhang Dou, Feng Yan. Porous alumina ceramic via gel-casting based on 2-hydroxyethyl methacrylate dissolved in tert-butyl alcohol. Transactions of Nonferrous Metals Society of China (in Chinese), 2019, 29(8): 1714-1720. |

| [27] | Liu Xueli, Yin Hongfeng, Ren Yun, Zhang Junzhan. Study on the preparation and properties porous Al2O3 ceramic by gel casting. Bulletin of the Chinese Ceramic Society (in Chinese), 2008, 27(6): 1162-1165. |

| [28] | Hao Bianlei, Chen Shile, Zhang Jian, Wang Chang’an. Preparation of porous Al2O3 ceramics by gel-casting with PMMA as pore-forming agent. Journal of the Chinese Ceramic Society (in Chinese), 2019, 47(9): 1242-1246. |

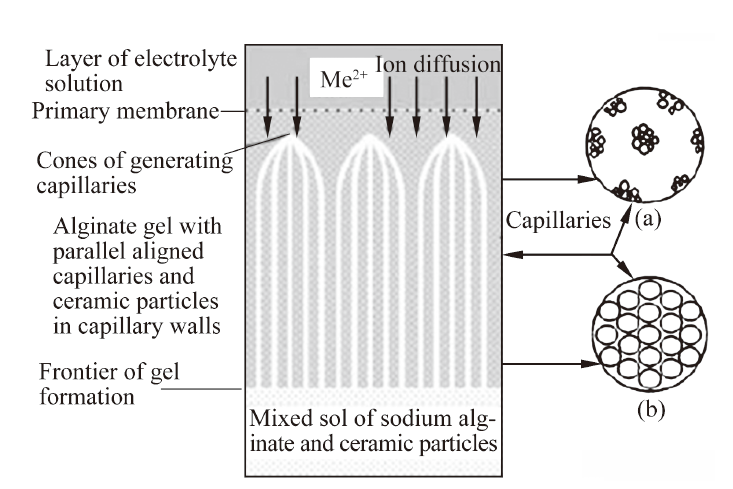

| [29] | A. A. Eljaouhari, R. Müller, M. Kellermeier, K. Heckmann, W. Kunz. New anisotropic ceramic membranes from chemically fixed dissipative structures. Langmuir, 2006, 22(26): 11353-11359. |

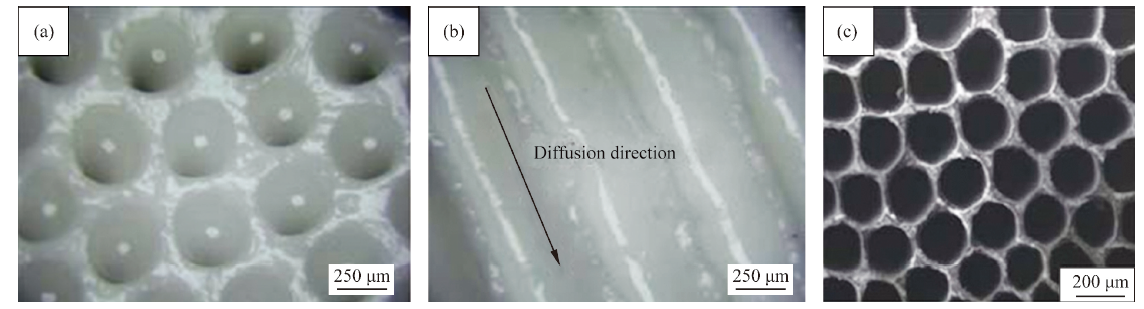

| [30] | Sun Yang, Xue Weijiang, Sun Jialin, Zhou Guozhi, Huang Yong. Porous alumina ceramics with unidirectional oriented pores fabricated by ionotropic process of sodium alginate. Journal of Inorganic Materials (in Chinese), 2015, 30(08): 877-881. |

| [31] | Scotti Kristen L., Dunand David C. Freeze casting—A review of processing, microstructure and properties via the open data repository, Freeze Casting. net. Progress in Materials Science, 2018, 94: 243-305. |

| [32] | Tang Yufei, Wu Cong, Zhao Kang. Fabrication of lamellar porous alumina with graded structures by combining centrifugal and directional freeze casting. Ceramics International, 2018, 44(5): 5794-5798. |

| [33] | W. M. Ketcham, P. V. Hobbs. The preferred orientation in the growth of ice from the melt. Journal of Crystal Growth, 1967, 1(5): 263-270. |

| [34] | P. Durán, J. Lachén, J. Plou, R. Sepúlveda, J. Herguido, J. A. Peña. Behaviour of freeze-casting iron oxide for purifying hydrogen streams by steam-iron process. International Journal of Hydrogen Energy, 2016, 41(43): 19518-19524. |

| [35] | Souza Douglas F., Nunes Eduardo H. M., Pimenta Daiana S., Vasconcelos Daniela C. L., Nascimento Jailton F., Grava Wilson, Houmard Manuel, Vasconcelos Wander L. Synthesis and structural evaluation of freeze-cast porous alumina. Materials Characterization, 2014, 96: 183-195. |

| [36] | Y. W. Moon, K. H. Shin, Y. H. Koh, W. Y. Choi, H. E. Kim. Production of highly aligned porous alumina ceramics by extruding frozen alumina/camphene body. Journal of the European Ceramic Society, 2011, 31(11): 1945-1950. |

| [37] | P. J. Alarco, L. Y. Abu, M. Armand. Highly conductive, organic plastic crystals based on pyrazolium imides. 14th International Conference on Solid State Ionics, Monterey,CA, 2003: 717-720. |

| [38] | D. Iwanov, D. Nenow. Equilibrium form of camphene crystals. Journal of Crystal Growth, 1999, 198(1): 96-100. |

| [39] | Sun Yang, Xue Weijiang, Huang Yong, Sun Jialin, Zhou Guozhi. Unidirectional porous alumina ceramics fabricated by freeze-drying process with sodium alginate. Journal of the Chinese Ceramic Society (in Chinese), 2015, 43(6): 709-715. |

| [40] | T. Kikuchi, T. Yamamoto, S. Natsui, R. O. Suzuki. Fabrication of anodic porous alumina by squaric acid anodizing. Electrochimica Acta, 2014, 123: 14-22. |

| [41] | An-Ping Li, F Muller, Albert Birner, Kornelius Nielsch, U Gosele. Hexagonal pore arrays with a 50-420 nm interpore distance formed by self-organization in anodic alumina. Journal of Applied Physics, 1998, 84(11): 6023-6026. |

| [42] | Woo Lee, Ran Ji, Ulrich Gösele, Kornelius Nielsch. Fast fabri-cation of long-range ordered porous alumina membranes by hard anodization. Nature Materials, 2006, 5(9): 741-747. |

| [43] | Woo Lee, Sang-Joon Park. Porous anodic aluminum oxide: anodization and templated synthesis of functional nanostructures. Chemical Reviews, 2014, 114(15): 7487-7556. |

| [44] | H. Masuda, F. Hasegwa, S. Ono. Self-ordering of cell arrangement of anodic porous alumina formed in sulfuric acid solution. Journal of the Electrochemical Society, 1997, 144(5): L127-L130. |

| [45] | T. Kikuchi, O. Nishinaga, S. Natsui, R. O. Suzuki. Self-ordering behavior of anodic porous alumina via selenic acid anodizing. Electrochimica Acta, 2014, 137: 728-735. |

| [46] | S. Akiya, T. Kikuchi, S. Natsui, N. Sakaguchi, R. O. Suzuki. Self-ordered porous alumina fabricated via phosphonic acid anodizing. Electrochimica Acta, 2016, 190: 471-479. |

| [47] | K. -J. Friedland, R. Hey, H. Kostial, K. H. Plog. Reduction of remote impurity scattering in heavily modulation-doped GaAs and (GaIn)As quantum wells with AlAs/GaAs type-Ⅱ-superlattice barriers. Japanese Journal of Applied Physics, 1998, 37(3): 1340-1342. |

| [48] | Xiufang Qin, Jinqiong Zhang, Xiaojuan Meng, Chenhua Deng, Lifang Zhang, Guqiao Ding, Hao Zeng, Xiaohong Xua. Preparation and analysis of anodic aluminum oxide films with continuously tunable interpore distances. Applied Surface Science, 2015, 328: 459-465. |

| [49] | Ryunosuke Kondo, Tatsuya Kikuchi, Shungo Natsui, Ryosuke O. Suzuki. Fabrication of self-ordered porous alumina via anodizing in sulfate solutions. Materials Letters, 2016, 183: 285-289. |

| [50] | Yu Fangli, Ni Shu, Bai Yu, Han Pengde, Shi Qingle, Zhang Changsen. Preparation and application progress of porous ceramics with unidirectionally oriented pores. Chinese Journal of Rare Metals (in Chinese), 2017, 41(2): 211-220. |

| [51] | Young Ki Hong, Bo Hyun Kim, Dong Il Kim, Dong Hyuk Park, Jinsoo Joo. High-yield and environment-minded fabrication of nonporous anodic aluminum oxide templates. RSC Advances, 2015, 5(34): 26872-26877. |

| [52] | Li Xiangming, Gao Mingjun, Jiang Yun. Microstructure and mechanical properties of porous alumina ceramic prepared by a combination of 3-D printing and sintering. Ceramics International, 2016, 42(10): 12531-12535. |

| [53] | Chen An-Nan, Wu Jia-Min, Liu Yu-Xuan, Liu Rong-Zhen, Cheng Li-Jin, Huo Wen-Long, Shi Yu-Sheng, Li Chen-Hui. Fabrication of porous fibrous alumina ceramics by direct coagulation casting combined with 3D printing. Ceramics International, 2017, 44(5): 4845-4852. |

| [54] | J. Cao, C. R. Rambo, H. Sieber. Preparation of porous Al2O3 ceramics by biotemplating of wood. Journal of Porous Materials, 2004, 11(3): 163-172. |

| [55] | Ma Yuan, Wei Qinglian, Ling Ruowen, An Fengkai, Mu Guangyu, Huang Yongmin. Synthesis of macro-mesoporous alumina with yeast cell as bio-template. Microporous and Mesoporous Materials, 2013, 165: 177-184. |

| [56] | Xiaofei Ji, Huanyu Zhang, Zhitao Bai, Guibo Qiu, Min Guo, Fangqin Cheng, Mei Zhang. Self-assembled multifunctional bulk hollow microspheres: Thermal insulation, sound absorption and fire resistance. Energy & Buildings, 2019, 205, 109533-1-109533-9. |

| [57] | Wenbing Zou, Xiaodong Wang, Yu Wu, Liping Zou, Guoqing Zu, Dong Chen, Jun Shen. Opacifier embedded and fiber reinforced alumina-based aerogel composites for ultra-high temperature thermal insulation. Ceramics International, 2018, 45(1): 644-650. |

| [58] | E. A. Sovinelli, A. P. Black. Defluoridation of water with activated alumina. Journal of American Water Works Association, 1958, 50(1): 33-44. |

| [59] | S. Ghorai, K. K. Pant. Investigations on the column performance of fluoride adsorption by activated alumina in a fixed-bed. Chemical Engineering Journal, 2004, 98(1-2): 165-173. |

| [60] | Y. X. Zhang, Y. Jia. Preparation of porous alumina hollow spheres as an adsorbent for fluoride removal from water with low aluminum residual. Ceramics International, 2016, 42(15): 17472-17481. |

| [61] | C. R. Rambo, T. Andrade, T. Fey, H. Sieber, A. E. Martinelli, P. Greil. Microcellular Al2O3 ceramics from wood for filter applications. Journal of the American Ceramic Society, 2008, 91(3): 852-859. |

| [62] | A. Kumar, K. Mohanta, D. Kumar, O. Parkashi. Low-cost porous alumina with tailored gas permeability and mechanical properties prepared using rice husk and sucrose for filter applications. Microporous and Mesoporous Materials, 2015, 213: 48-58. |

| [63] | Haizhi Wang, Lili Sun, Zhijun Sui, Yian Zhu, Weikang Yuan. Coke formation on Pt-Sn/Al2O3 catalyst for propane dehydrogenation. Industrial & Engineering Chemistry Research, 2018, 57(26): 8647-8654. |

| [64] | Gao Xinqian, Lu Wenduo, Hu Shouzhao, Li Wencui, Lu Anhui. Rod-shaped porous alumina-supported Cr2O3 catalyst with low acidity for propane dehydrogenation. Chinese Journal of Catalysis, 2019, 40(2): 184-191. |

| [65] | S. P. Bennett, L. Menon, D. Heiman. Magnetic properties of GaMnAs nanodot arrays fabricated using porous alumina templates. Journal of Applied Physics, 2008, 104(2), 024309-1-024309-4. |

| [66] | M. Bendova, Z. Pytlicek, J. Prasek, A. Mozalev. The growth and unique electronic properties of the porous-alumina-assisted hafnium-oxide nanostructured films. Electrochimica Acta, 2019, 327, 135029-1-135029-12. |

| [67] | A. Harizi. Microstructural and optical properties of Sn4Sb6S13 nanocrystals deposited on PAA templates. Materials Research Bulletin, 2020, 125, 110791-1-110791-10. |

| [1] | Burhanuddin, Harald HARMUTH. Effect of Slag Basicity on Alumina Dissolution and Diffusivity: A High-temperature Confocal Laser Scanning Microscopy Study [J]. China's Refractories, 2024, 33(2): 27-34. |

| [2] | Yunpeng ZHOU, Wang FENG, Shankha CHATTERJEE, Andus BUHR, Sebastian KLAUS. Study on Chrome-free Purging Plugs for Steel Ladles [J]. China's Refractories, 2024, 33(2): 41-47. |

| [3] | Valeriy V. MARTYNENKO, Iryna G. SHULYK, Yuliya Ye. MISHNYOVA, Tetyana G. TYSHYNA. Investigation of Microstructure and Phase Composition of Chromic Oxide, AZS/Cr and High-alumina Refractories after Exposure of Basalt and Aluminaboronsilicate Glasses Melts [J]. China's Refractories, 2024, 33(1): 1-6. |

| [4] | WANG Jia, SUN Xiaofei, XU Jianfeng, XU Peipei. Effects of Different Raw Materials and Additions on Wave Transparency of Alumina Fiber Products [J]. China's Refractories, 2024, 33(1): 40-43. |

| [5] | WANG Li, LIU Shijie, WEI Haoyu, MA Juanjuan, DONG Binbin, GENG Shangrui, YAN Miaoxin, QIN Feng, GUO Yusen. Aluminum and Activated Alumina Powder Additions on Microwave Synthesis of Al4SiC4 [J]. China's Refractories, 2024, 33(1): 44-48. |

| [6] | LIU Chenchen, HUANG Ao, NIE Jianhua, GU Huazhi, QIN Chuanjiang, Lidah Mpoli NACHILIMA. Corrosion Mechanism of Alumina-magnesia Dry Materials for Smelting Manganese/chromium Steel in Coreless Medium Frequency Induction Furnaces [J]. China's Refractories, 2023, 32(4): 8-15. |

| [7] | LEE Yaotsung, ZHAO Lite, LEE Johnson, LIU William. Analysis of Corrosion Mechanisms of Low-cement or No-cement Al2O3-MgO Gunning Mix with Special Calcined Alumina in Rotary Slag Test [J]. China's Refractories, 2023, 32(4): 16-21. |

| [8] | ZOU Xin, CHEN Ping’an, XU Guangping, LI Xiangcheng, ZHU Yingli, ZHU Boquan. Sintering Densification of Boron Carbide Materials and Their Research Progress [J]. China's Refractories, 2023, 32(4): 22-27. |

| [9] | ZHANG Yifan, WANG Gang, WANG Qu, LU Keke, ZHANG Qi. Effect of ZrO2 Addition on Lanthanum Aluminate-based High Emissivity Coating Materials [J]. China's Refractories, 2023, 32(4): 38-41. |

| [10] | ZHANG Keke, QIN Feng, YAN Miaoxin, LIU Shijie, LI Xuhao, GUO Yusen, WANG Li, YIN Chaofan, DONG Binbin. Progress in Preparation Technology of Porous Ceramics for High Temperature Dust Filtration [J]. China's Refractories, 2023, 32(4): 42-51. |

| [11] | ZHOU Lianzhuo, WANG Zhoufu, WANG Xitang, LIU Hao, MA Yan, QUAN Zhenghuang. Effect of Al Powder and Si Powder Additions on Structure and Properties of Unburned Magnesium Aluminate Spinel Refractories [J]. China's Refractories, 2023, 32(3): 14-19. |

| [12] | ZAN Wenyu, MA Beiyue. Preparation of Lightweight Alumina-silica Castables by Replacing Closed-cell Perlite Aggregates with Coal Gangue Ceramsites [J]. China's Refractories, 2023, 32(3): 20-25. |

| [13] | LIU Shijie, WANG Li, DONG Binbin, XU Biao, GUO Yusen, MIN Yongchao, GUO Yanyan, WEI Haoyu, ZHANG Keke, YIN Chaofan. Ultra-high Temperature Ceramic Coatings: A Review on Preparation Technology and Development Prospect [J]. China's Refractories, 2023, 32(3): 42-49. |

| [14] | FAN Muxu, HOU Xiaojing, FENG Zhiyuan, WANG Han, LIU Pengcheng, SHI Gan. Alkali Vapor Corrosion of Different Refractories at High Temperatures [J]. China's Refractories, 2023, 32(2): 24-30. |

| [15] | CAO Zhuang, JIA Qingwei, ZHANG Jun, ZHOU Huijun, LI Jinfeng, HUN Xianlei, YAN Leixin, QIN Hongbin, ZHANG Sanhua. Effect of Different Silica Fumes on Properties of Al2O3-SiC-C Castables for Iron Trough [J]. China's Refractories, 2023, 32(2): 31-36. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||