| [1] |

Valeriy V. MARTYNENKO, Iryna G. SHULYK, Yuliya Ye. MISHNYOVA, Tetyana G. TYSHYNA.

Investigation of Microstructure and Phase Composition of Chromic Oxide, AZS/Cr and High-alumina Refractories after Exposure of Basalt and Aluminaboronsilicate Glasses Melts

[J]. China's Refractories, 2024, 33(1): 1-6.

|

| [2] |

DU Juan, GUO Huishi, YANG Jialin, LI Wenfeng, GUI Yanghai, ZHAO Zhiqiang, LIU Yingfan.

Effects of Al2O3-SiO2 Raw Material Types on Properties of Anorthite Based Insulation Refractories

[J]. China's Refractories, 2024, 33(1): 23-27.

|

| [3] |

JIN Zhishang, SHAN Zhilin, ZHAO Huizhong, YU Jun, ZHANG Han.

Effect of Porogenic Agents on Properties of Microporous Mullite Aggregates

[J]. China's Refractories, 2023, 32(3): 31-35.

|

| [4] |

CAO Huiyan, ZHANG Xinhua, HUANG Yifei, WANG Wenwu, WU Jiguang, BU Xiangjuan, XU Haiyang.

Influence of Graphite on Molten-alkali Corrosion Resistance for β-SiAlON-SiC Materials

[J]. China's Refractories, 2022, 31(4): 22-27.

|

| [5] |

CHENG Shuiming, CHEN Jinfeng, WEI Jianxiu, CAI Wei, ZHAO Huizhong.

Effect of Submicron SiO2 Powder Addition on Properties of Cement Free Iron Trough Castables

[J]. China's Refractories, 2022, 31(3): 9-13.

|

| [6] |

YAN Mingwei, YANG Yumin, TONG Shanghao, ZHANG Jiayu, SUN Guangchao, LIU Kaiqi.

Phase Reconstruction and Microstructure Evolution of Magnesia-carbon Refractories at High Temperatures in Nitrogen

[J]. China's Refractories, 2022, 31(3): 14-23.

|

| [7] |

LYU Lihua, DING Donghai, XIAO Guoqing.

Combustion Synthesis of C/MgAl2O4 Composite Powders and Their Microstructure Evolution

[J]. China's Refractories, 2021, 30(4): 7-11.

|

| [8] |

LI Youqi, WANG Bingwei, ZHANG Yucui, BI Changlu, ZHAO Jizeng.

Effect of Industrial Alumina Powder Particle Size on Preparation of Active α-Al2O3 Micropowder

[J]. China's Refractories, 2021, 30(3): 11-16.

|

| [9] |

ZHANG Qi, YUAN Bo, WANG Gang, HAN Jianshen, ZHAO Xin.

Effect of Nitriding Process on Phase and Microstructure of Silicon Nitride Fibers Prepared by Direct Nitriding Method

[J]. China's Refractories, 2020, 29(4): 40-45.

|

| [10] |

GAO Zhenxin.

Phase Relationship at Subsolidus Tem-perature of MgO-MgAl2O4-ZrO2 Subsystem

[J]. China's Refractories, 2020, 29(1): 1-6.

|

| [11] |

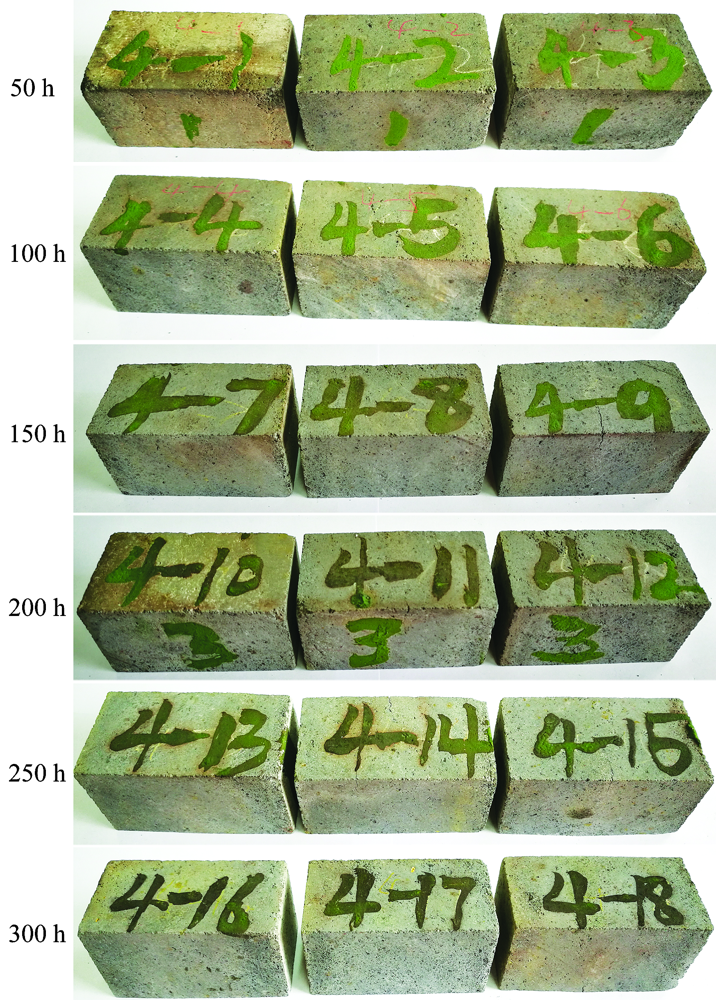

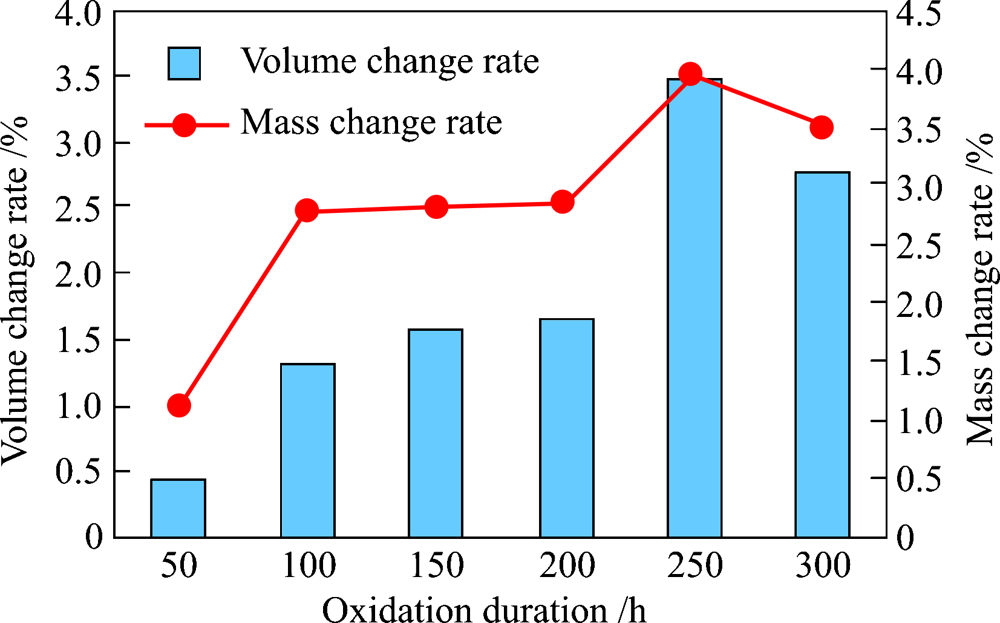

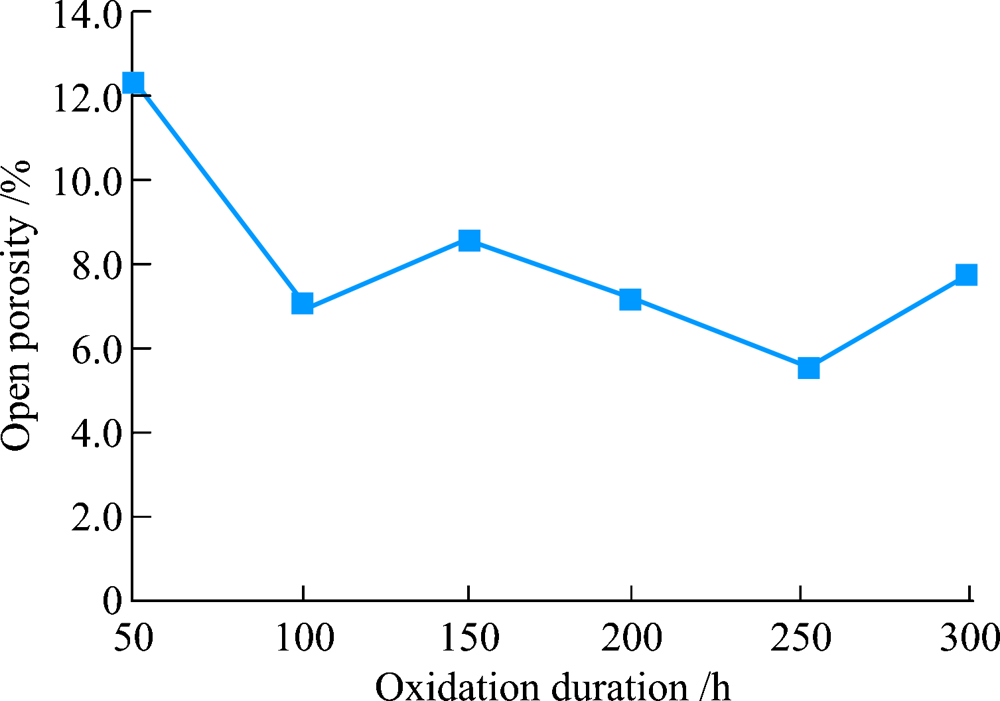

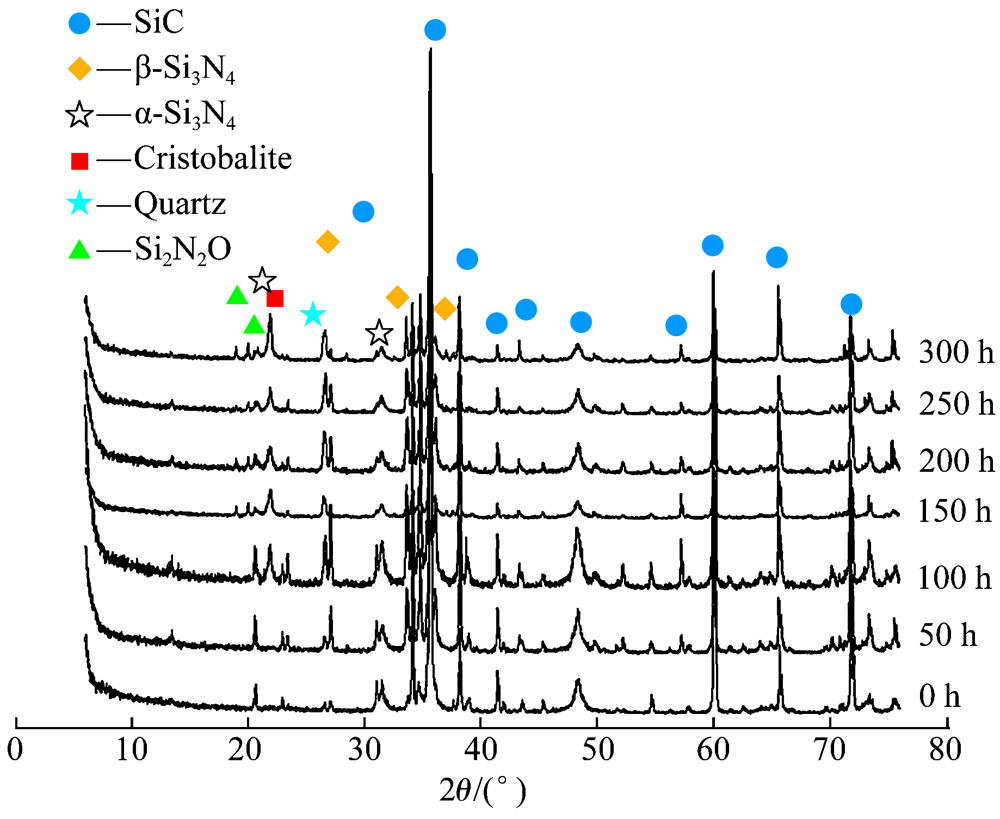

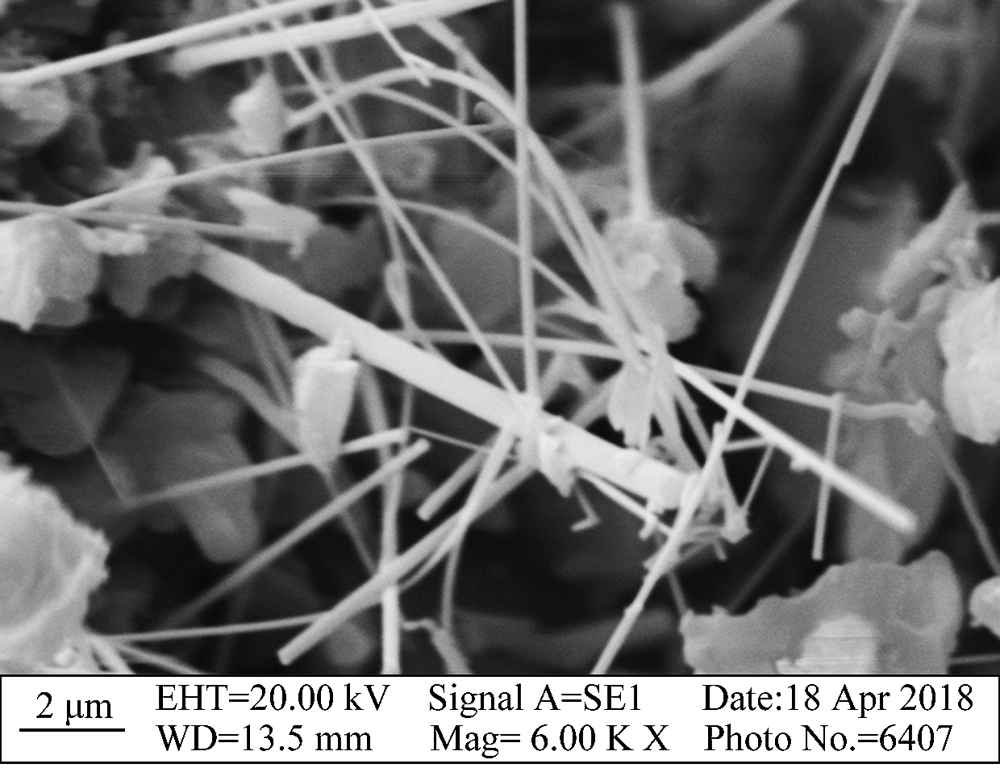

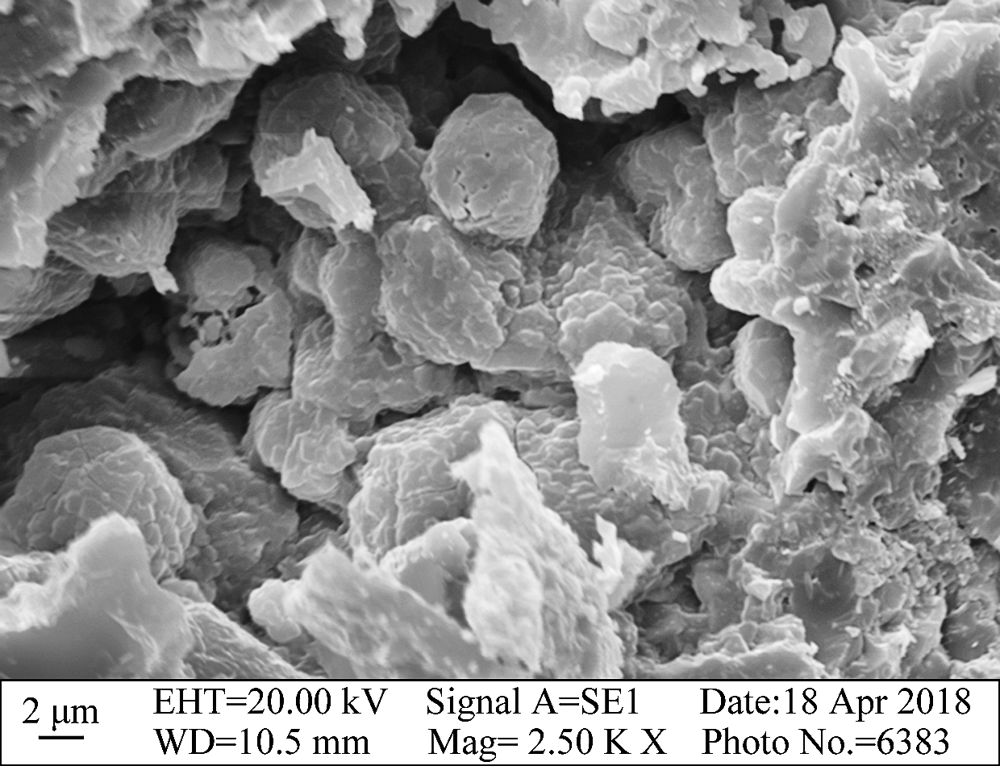

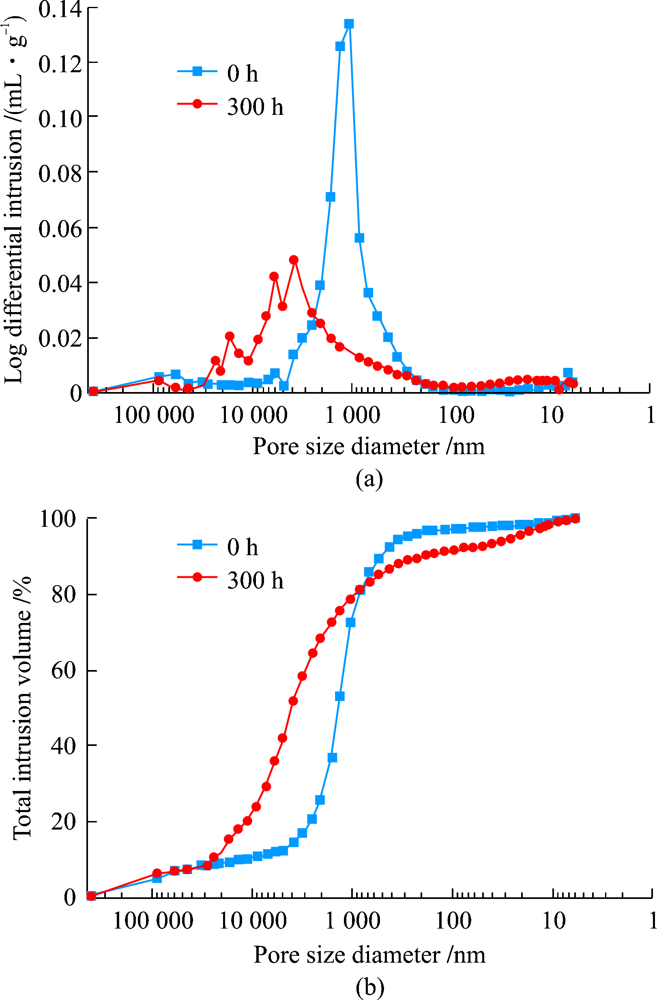

HUANG Zhigang*, WANG Jiaping, LI Jie, CAO Huiyan, WU Jiguang.

Steam Oxidation Resistance of Nitride Bonded Silicon Carbide Refractories for Waste Incinerators at Elevated Temperatures

[J]. , 2019, 28(3): 4-7.

|

| [12] |

YI Shuai, DENG Lina, ZENG Luju, XUE Fei, PAN Chuancai, LIN Guowei, LIU Yueqiang, ZHANG Hang, XIE Jinli.

Effects of Chemical Composition and Microstructure on Exudation of Fused Cast AZS Refractory Materials

[J]. , 2019, 28(2): 23-26.

|

| [13] |

Debasish CHANDRA.

Comparison of Physico-mechanical Properties of TiO2 and Cr2O3 Additives on Reaction Sintered Zirconia-mullite Composites

[J]. , 2019, 28(1): 11-21.

|

| [14] |

YE Hang, SUN Gaoyang, ZHANG Haibo, LI Yanjing, GAO Changhe, LI Yong, YE Fangbao.

Investigation on Synthesis of Sintered Mullite from Low-medium Grade Kyanite

[J]. , 2019, 28(1): 22-30.

|

| [15] |

Andreas BÖRGER, Johan LORICOURT, Angelika PRIESE.

Influence of Impurities of Zircon Sand on the Microstructure of Fused Zirconia Grains for Continuous Casting of Steel Refractories

[J]. , 2018, 27(1): 1-7.

|

), HUANG Zhigang, ZHANG Xinhua, LIU Zhen

), HUANG Zhigang, ZHANG Xinhua, LIU Zhen