| [1] |

Yang Shoulei, Ding Donghai, Xiao Guoqing. Research status of carbon-containing refractory castables. Naihuo Cailiao (Refractories, in Chinese), 2021,55(3):251-257.

|

| [2] |

Li Zhongke, Huang Zihao, Zheng Jiashun, Liu Tong, Jiang Tianbao, Wu Qinxin, Wei Juncong, Tu Junbo. Preparation of B4C-graphitized carbon black composite powders by microwave sintering method. Naihuo Cailiao (Refractories, in Chinese), 2020,54(1):37-40.

|

| [3] |

Ming Luo, Yawei Li, Shengli Jin, Shaobai Sang, Lei Zhao, Qinghu Wang, Yuanbing Li. Microstructure and mechanical properties of multi-walled carbon nanotubes containing Al2O3-C refractories with addition of polycarbosilane. Ceramics International, 2013,39(5):4831-4838.

|

| [4] |

Tianbin Zhu, Yawei Li, Ming Luo, Shaobai Sang, Qinghu Wang, Lei Zhao, Yuanbing Li, Shujing Li. Microstructure and mechanical properties of MgO-C refractories containing graphite oxide nanosheets (GONs). Ceramics International, 2013,39(3):3017-3025.

|

| [5] |

Feng Liang, Nan Li, Baikuan Liu, Zhongyang He. Processing and characterization of multi-walled carbon nanotubes containing alumina-carbon refractories prepared by nanocomposite powder technology. Metallurgical and Materials Transactions B, 2016,47(3):1661-1668.

|

| [6] |

Huczko Andrzej, Kurcz Magdalena, Dabrowska Agnieszka, Bystrzejewski Michal, Strachowski Przemyslaw, Dyjak Slawomir, Bhatta Rita, Pokhrel Balram, Kafle Bhim Prasad, Subedi Deepak. Self-propagating high-temperature fast reduction of magnesium oxalate to novel nanocarbons. Physica Status Solidi B Basic Research, 2016,253(12):286-2491.

|

| [7] |

Li Fei, Qu Chengbing, Hua Yang, Xiao Hongmei, Fu Shaoyun. Largely improved dimensional stability of short carbon fiber reinforced polyethersulfone composites by graphene oxide coating at a low content. Carbon, 2017,119:339-349.

|

| [8] |

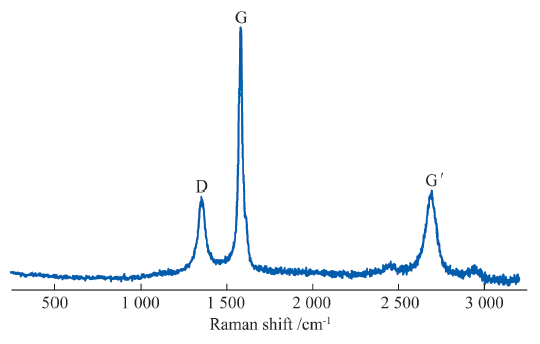

Andrea C. Ferrari. Raman spectroscopy of graphene and graphite: disorder, electron-phonon coupling, doping and nonadiabatic effects. Solid State Communications, 2007,143(1):47-57.

|

| [9] |

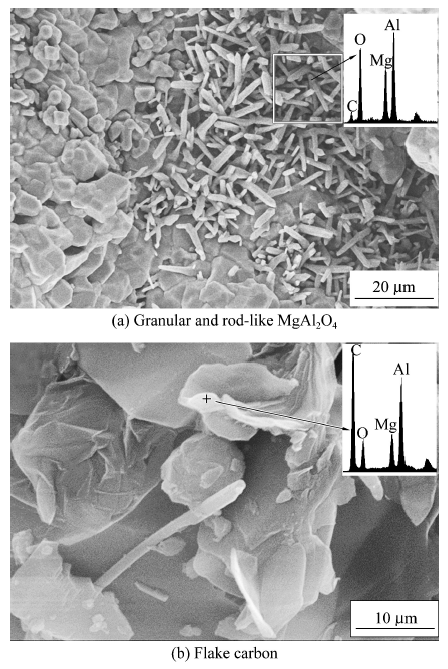

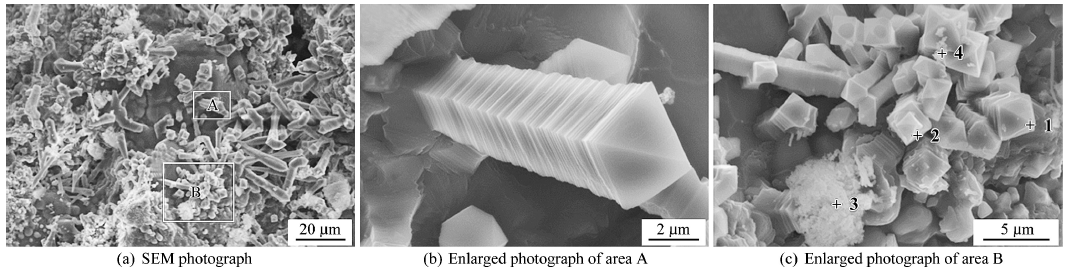

Riitsu Takagi. Growth of oxide whiskers on metals at high temperature. Journal of the Physical Society of Japan, 1957,12(11):1212-1218.

|

| [10] |

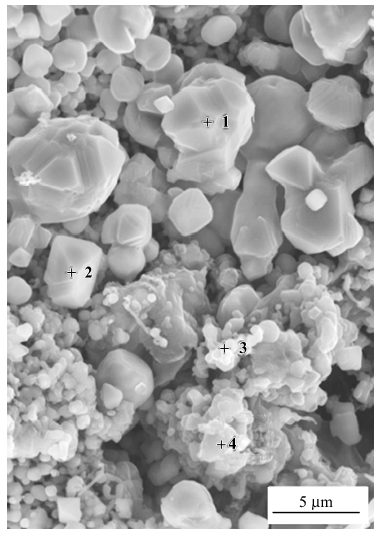

Li Laiqiang, Wang Shulin, Han Guangqiang, Chen Xingjian. Preparation and growth mechanism of nanostructure ZnO by gas-solid reaction. Materials for Mechanical Engineering (in Chinese), 2010,34(8):75-78.

|