China's Refractories ›› 2020, Vol. 29 ›› Issue (1): 1-6.DOI: 10.19691/j.cnki.1004-4493.2020.01.001

• Original article • Next Articles

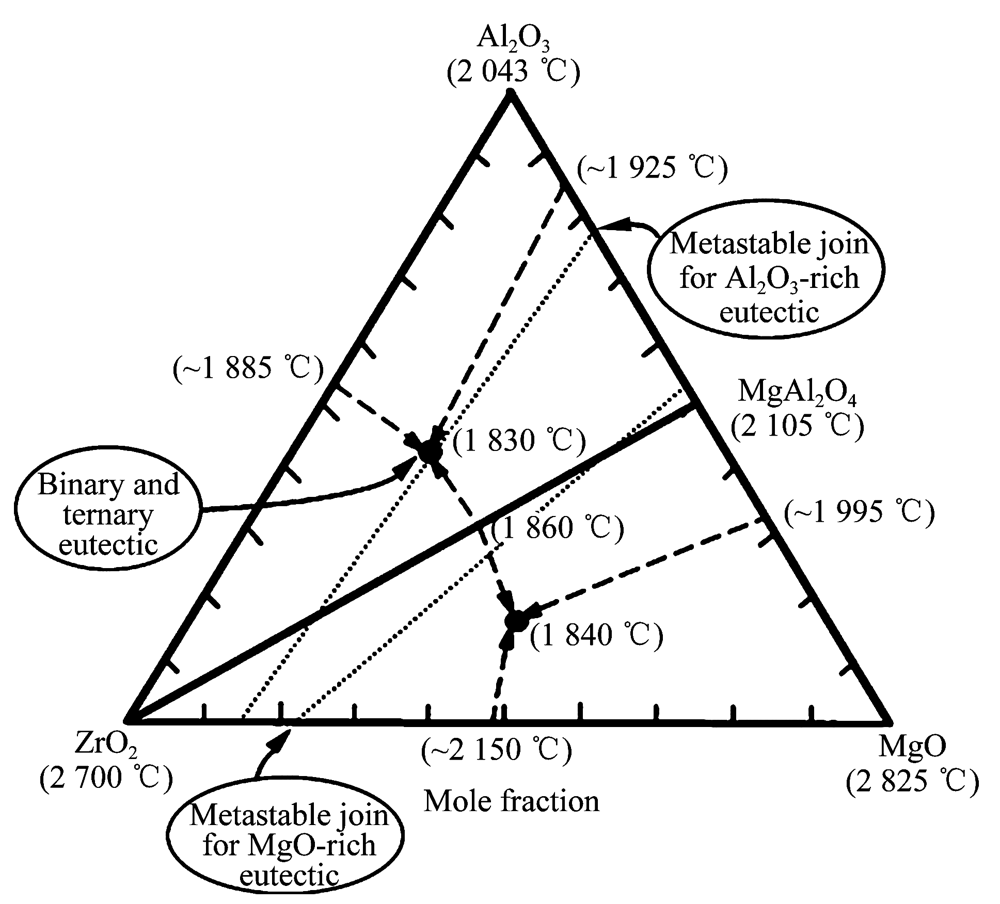

Phase Relationship at Subsolidus Tem-perature of MgO-MgAl2O4-ZrO2 Subsystem

- 1 Sinosteel Luoyang Institute of Refractories Research Co., Ltd., Luoyang 471039, China

2 Beijing Research and Development Center of Puyang Refractories Group Co., Ltd.,Beijing 100039, China

-

Online:2020-01-10Published:2020-01-10 -

Contact:GAO Zhenxin -

About author:Prof. Gao Zhenxin joined Tangshan Steel Plant in 1953. In 1972, he transferred to Luoyang Institute of Refractories Research of the Ministry of Metallurgy (now Sinosteel Luoyang Institute of Refractories Research Co., Ltd.). He has worked for more than 60 years and published more than 90 papers, 4 monographs and 1 translation book.

Cite this article

GAO Zhenxin. Phase Relationship at Subsolidus Tem-perature of MgO-MgAl2O4-ZrO2 Subsystem[J]. China's Refractories, 2020, 29(1): 1-6.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2020.01.001

| Specimens | Formulations /mass/% | Designed MA contents /mass/% | Locations | ||

|---|---|---|---|---|---|

| MgO | Al2O3 | ZrO2 | |||

| 1# | 32 | 48 | 20 | 66 | In the M-MA-Z area close to the MA-Z join |

| 2# | 20 | 50 | 30 | 70 | On the MA-Z join |

| 3# | 37 | 23 | 40 | 32 | In the center of M-MA-Z area |

Table 1 Formulations of specimens and their locations in phase diagram

| Specimens | Formulations /mass/% | Designed MA contents /mass/% | Locations | ||

|---|---|---|---|---|---|

| MgO | Al2O3 | ZrO2 | |||

| 1# | 32 | 48 | 20 | 66 | In the M-MA-Z area close to the MA-Z join |

| 2# | 20 | 50 | 30 | 70 | On the MA-Z join |

| 3# | 37 | 23 | 40 | 32 | In the center of M-MA-Z area |

| Specimens | Linear shrinkage rate /% | Bulk density / (g · cm-3) |

|---|---|---|

| 1# | 10.7 | 3.00 |

| 2# | 4.7 | 2.74 |

| 3# | 19.6 | 3.75 |

Table 2 Linear shrinkage rate and bulk density of specimens fired at 1 600 ℃ for 5 h

| Specimens | Linear shrinkage rate /% | Bulk density / (g · cm-3) |

|---|---|---|

| 1# | 10.7 | 3.00 |

| 2# | 4.7 | 2.74 |

| 3# | 19.6 | 3.75 |

| [1] | P. Tassot, G. Konig, F. Seifert, F. Liebau . Subsolidus, high temperature phase relations in the systems Al2O3-Cr2O3-ZrO2, MgO-Cr2O3-ZrO2 and MgO-Al2O3-ZrO2. Journal of Material Science, 1986,21(10):3479-3482. |

| [2] | Joanna McKittrick, Gretchen Kalonji . Non-stoichiometry and defect structures in rapidly solidified MgO-Al2O3-ZrO2 ternary eutectics. Material Science Engineering A, 1997,231:90-97. |

| [3] | Gao Zhenxin . Phase relationship of Al2O3-ZrO2-SiO2 system. Naihuo Cailiao (Refractories,in Chinese), 2019,53(3):161-165. |

| [4] | D. Pavlyuchkov, G. Savinykh, O. Fabrichnaya . Experimental investigation and thermodynamic modeling of the MgO-Al2O3-ZrO2 system. Journal of the European Ceramic Society, 2014,34(5):1396-1408. |

| [5] | P. Tassot, G. Konig, F. Liebau, F. Seifert . A new magnesium aluminium zirconium oxide, Mg5+xAl2.4-xZr1.7+0.25xO12 with -0.4≤x≤0.4. Journal of Applied Crystallography, 1983,16(6):649. |

| [6] | БЕЛЕЖНОЙ А С, КОРДЮК Р А . Диаграмма Плавкости Системы MgO-Al2O3-ZrO2. ДАН УССР, 1964,4(4):506-507. |

| [7] | Gao Zhenxin . Phase relationship of MgO-Al2O3-ZrO2 system. Naihuo Cailiao (Refractories,in Chinese), 2017,51(1):68-73. |

| [8] | A. S. Berezhnoi, R. A. Korduk . Melting diagram of the MgO-Al2O3-ZrO2 system. DAN URSR, 1964,4(10):506-508. |

| [1] | Valeriy V. MARTYNENKO, Iryna G. SHULYK, Yuliya Ye. MISHNYOVA, Tetyana G. TYSHYNA. Investigation of Microstructure and Phase Composition of Chromic Oxide, AZS/Cr and High-alumina Refractories after Exposure of Basalt and Aluminaboronsilicate Glasses Melts [J]. China's Refractories, 2024, 33(1): 1-6. |

| [2] | DU Juan, GUO Huishi, YANG Jialin, LI Wenfeng, GUI Yanghai, ZHAO Zhiqiang, LIU Yingfan. Effects of Al2O3-SiO2 Raw Material Types on Properties of Anorthite Based Insulation Refractories [J]. China's Refractories, 2024, 33(1): 23-27. |

| [3] | CAO Huiyan, ZHANG Xinhua, HUANG Yifei, WANG Wenwu, WU Jiguang, BU Xiangjuan, XU Haiyang. Influence of Graphite on Molten-alkali Corrosion Resistance for β-SiAlON-SiC Materials [J]. China's Refractories, 2022, 31(4): 22-27. |

| [4] | CHENG Shuiming, CHEN Jinfeng, WEI Jianxiu, CAI Wei, ZHAO Huizhong. Effect of Submicron SiO2 Powder Addition on Properties of Cement Free Iron Trough Castables [J]. China's Refractories, 2022, 31(3): 9-13. |

| [5] | YAN Mingwei, YANG Yumin, TONG Shanghao, ZHANG Jiayu, SUN Guangchao, LIU Kaiqi. Phase Reconstruction and Microstructure Evolution of Magnesia-carbon Refractories at High Temperatures in Nitrogen [J]. China's Refractories, 2022, 31(3): 14-23. |

| [6] | LYU Lihua, DING Donghai, XIAO Guoqing. Combustion Synthesis of C/MgAl2O4 Composite Powders and Their Microstructure Evolution [J]. China's Refractories, 2021, 30(4): 7-11. |

| [7] | LI Youqi, WANG Bingwei, ZHANG Yucui, BI Changlu, ZHAO Jizeng. Effect of Industrial Alumina Powder Particle Size on Preparation of Active α-Al2O3 Micropowder [J]. China's Refractories, 2021, 30(3): 11-16. |

| [8] | ZHANG Qi, YUAN Bo, WANG Gang, HAN Jianshen, ZHAO Xin. Effect of Nitriding Process on Phase and Microstructure of Silicon Nitride Fibers Prepared by Direct Nitriding Method [J]. China's Refractories, 2020, 29(4): 40-45. |

| [9] | CAO Huiyan, HUANG Zhigang, ZHANG Xinhua, LIU Zhen. Research on Steam Oxidation Resistance of Si3N4-bonded SiC Refractories [J]. China's Refractories, 2020, 29(1): 44-47. |

| [10] | YI Shuai, DENG Lina, ZENG Luju, XUE Fei, PAN Chuancai, LIN Guowei, LIU Yueqiang, ZHANG Hang, XIE Jinli. Effects of Chemical Composition and Microstructure on Exudation of Fused Cast AZS Refractory Materials [J]. , 2019, 28(2): 23-26. |

| [11] | Debasish CHANDRA. Comparison of Physico-mechanical Properties of TiO2 and Cr2O3 Additives on Reaction Sintered Zirconia-mullite Composites [J]. , 2019, 28(1): 11-21. |

| [12] | YE Hang, SUN Gaoyang, ZHANG Haibo, LI Yanjing, GAO Changhe, LI Yong, YE Fangbao. Investigation on Synthesis of Sintered Mullite from Low-medium Grade Kyanite [J]. , 2019, 28(1): 22-30. |

| [13] | Andreas BÖRGER, Johan LORICOURT, Angelika PRIESE. Influence of Impurities of Zircon Sand on the Microstructure of Fused Zirconia Grains for Continuous Casting of Steel Refractories [J]. , 2018, 27(1): 1-7. |

| [14] | ZHOU Yandun, WU Xingsheng, HU Jianhui, WANG Juntao. Impact of Bauxite on Performance and Structure of SiC-mullite Brick [J]. , 2018, 27(1): 35-38. |

| [15] | LIU Jiangbo, WANG Zhoufu, LIU Hao, WANG Xitang, MA Yan. Effect of Y2O3 Addition on Sintering Properties and Microstructure of Spinel Materials [J]. , 2018, 27(1): 39-43. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||