China's Refractories ›› 2022, Vol. 31 ›› Issue (2): 24-29.DOI: 10.19691/j.cnki.1004-4493.2022.02.005

Previous Articles Next Articles

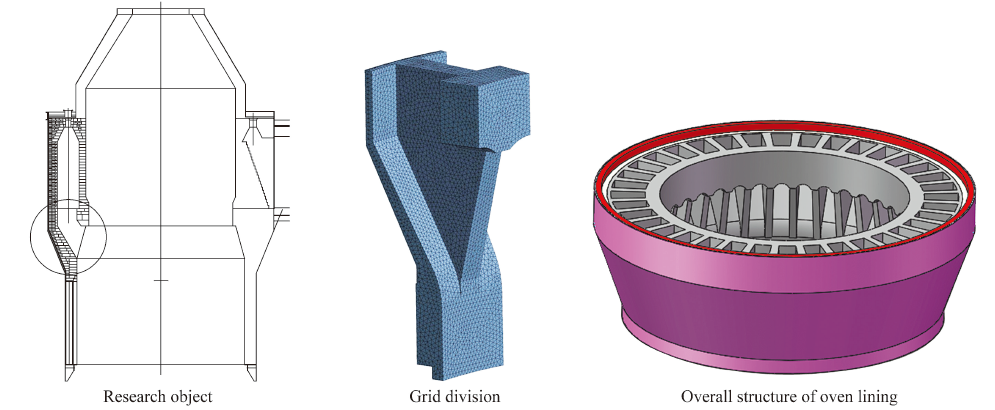

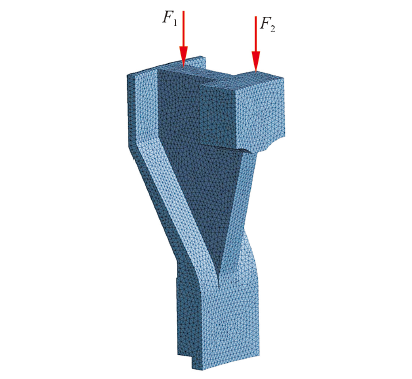

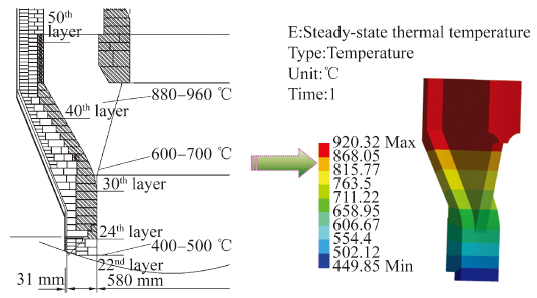

Optimization and Simulation of Inclined Channel Area Lining for CDQ Ovens

CAO Huiyan*( ), FENG Yanbin, ZHANG Haiyan, MA Zhaoyang, LI Jie, WANG Xinhui, WU Jiguang, YANG Wengang

), FENG Yanbin, ZHANG Haiyan, MA Zhaoyang, LI Jie, WANG Xinhui, WU Jiguang, YANG Wengang

- State Key Laboratory of Advanced Refractories, Luoyang Institute of Refractories Research Co., Ltd., Luoyang 471039, China

-

Online:2022-06-15Published:2022-07-05 -

Contact:CAO Huiyan -

About author:Cao Huiyan, born in 1982, obtained her master’s degree in 2008. She has been working in Sinosteel Luoyang Institute of Refractories Research Co., Ltd. since 2008. She commits herself for advanced SiC series refractories research and market development for more than 10 years. As a senior engineer, she is skilled in technical services and engineering guidance for SiC products, especially Si3N4 bonded SiC applied in aluminum reduction cell sidewall and Si3N4/SiAlON bonded SiC applied in stack, belly and bosh liner, and also tuyere assembly brick or tuyere block of blast furnaces, CDQ (especially for inclined channel area), SiC Muffle in heat treatment furnaces, sintered SiC ceramic slurry pump and SiC products with excellent steam oxidation used in WTE incinerators. She has authored and co-authored about 40 papers.

Cite this article

CAO Huiyan, FENG Yanbin, ZHANG Haiyan, MA Zhaoyang, LI Jie, WANG Xinhui, WU Jiguang, YANG Wengang. Optimization and Simulation of Inclined Channel Area Lining for CDQ Ovens[J]. China's Refractories, 2022, 31(2): 24-29.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2022.02.005

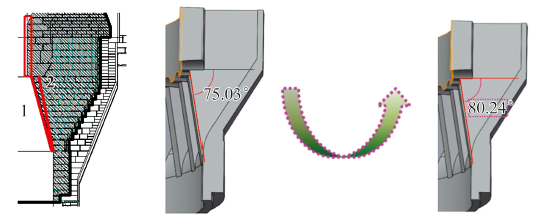

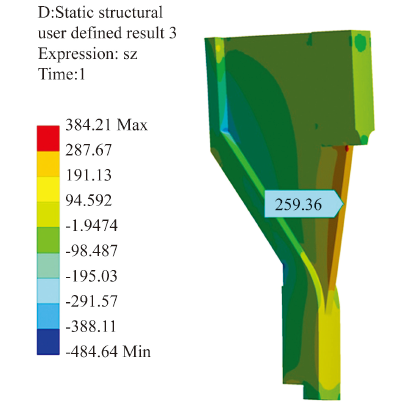

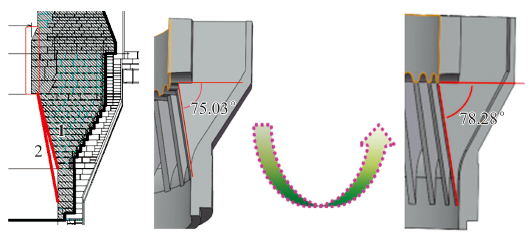

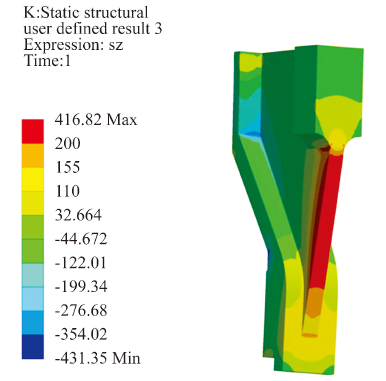

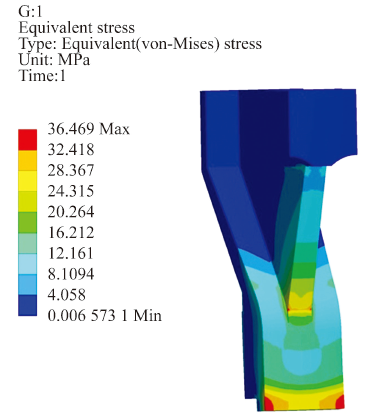

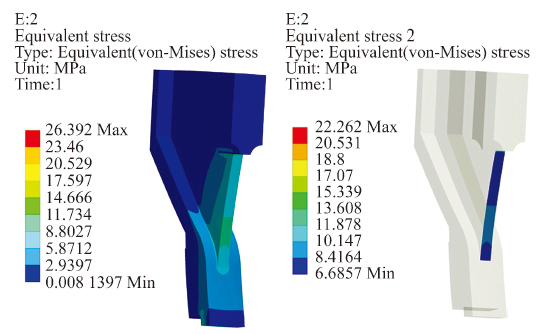

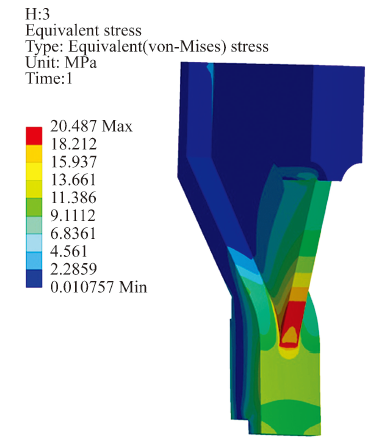

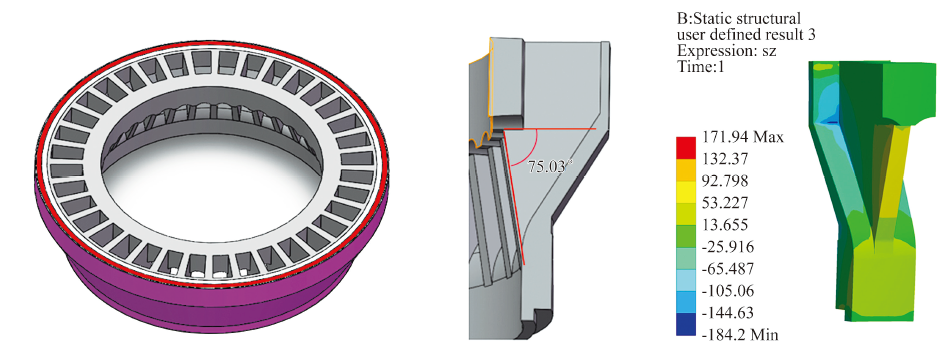

| Comparison | Change | Result |

|---|---|---|

| Original structure and scheme I | “Bracket” inclination angle from 75.03° to 80.24° | Little effect on “bracket” stress; stress concentration hardly changes; maximum stress increases a little. |

| Original structure and scheme II | “Bracket” number from 36 to 30 | Little effect on “bracket” stress; stress concentration moves upwards; maximum stress increases a lot. |

| Original structure and scheme III | “Bracket” inclination angle from 75.03° to 78.28° | Little effect on “bracket” stress; stress concentration hardly changes; maximum stress increases a lot. |

Table 1 Simulation results of first round thermodynamic simulation

| Comparison | Change | Result |

|---|---|---|

| Original structure and scheme I | “Bracket” inclination angle from 75.03° to 80.24° | Little effect on “bracket” stress; stress concentration hardly changes; maximum stress increases a little. |

| Original structure and scheme II | “Bracket” number from 36 to 30 | Little effect on “bracket” stress; stress concentration moves upwards; maximum stress increases a lot. |

| Original structure and scheme III | “Bracket” inclination angle from 75.03° to 78.28° | Little effect on “bracket” stress; stress concentration hardly changes; maximum stress increases a lot. |

| [1] | Zhang Xiongfei, Liu Yuhu. Technical advantages and equipment innovation for high capacity CDQ plant. Fuel and Chemical Processes, 2020, 51(1): 25-27. (in Chinese) |

| [2] | Wu Jiguang, Huang Zhigang, Zhang Xinhua, Zhou Jiwei, Chang Cheng, Li Jie. Status and development of refractories in the chute area of CDQ furnace. Proceedings of 2014 National Ironmaking Production Technology Conference and Annual Ironmaking Academic Conference, Zhengzhou, China, 2014: 288-293. (in Chinese) |

| [3] | Wang Jiaping, Jin Guangxiang, Wang Yongfeng, Li Jie, Huang Zhigang, Wang Xinhui. Application and analysis of new multiphase nitride bonded silicon carbide refractories in inclined area of CDQ ovens. Proceedings of 2016 (10th) Coking Energy Saving, Environmental Protection and CDQ Technology Seminar (in Chinese), Xi'an, China, 2016: 96-101. (in Chinese) |

| [4] | Wang Xinhui, Huang Jiayuan, Yang Fengling. Refractories selection for CDQ chamber and whole life cycle cost analysis. Refractories and Lime, 2019, 44(4): 10-14. (in Chinese) |

| [5] | Zhou Yang, Tan Chao, Chen Jie, Wang Yongfeng. Application of complex-SiC brick in CDQ chamber of Lysteel. Metal Materials and Metallurgy Engineering, 2017, 45(4):58-64. (in Chinese) |

| [6] | Cao Huiyan, Li Jie, Huang Zhigang, Wang Xinhui, Wu Jiguang. Effect of B4C on CO corrosion resistance of multi-phase nitride bonded SiC materials. Naihuo Cailiao (Refractories, in Chinese), 2020, 54(6): 522-525. |

| [7] | Cao Huiyan, Li Jie, Huang Zhigang, Wang Xinhui, Wu Jiguang. Development and application of multiphase nitride bonded silicon carbide large lintel brick for CDQ ovens. Proceedings of 2018 (12th) Coking Energy Saving, Environmental Protection and CDQ Technology Seminar (in Chinese), Dalian, China, 2018: 93-98 (in Chinese) |

| [8] | Huang Zhigang, Cao Huiyan, Li Jie, Wang Jiaping, Huang Yifei. Degradation mechanism of Si3N4 bonded SiC lintel bricks for dry quenching coke oven. Naihuo Cailiao (Refractories, in Chinese), 2019, 53(3): 175-179. |

| [9] | Li Jie, Cao Huiyan, Huang Zhigang. CO resistance of SiC refractories for CDQ furnace. Naihuo Cailiao (Refractories, in Chinese), 2019, 53(6): 464-467. |

| [10] | Wang Xibo, Xu Guotao, Liu Wei, Cai Guoqing, Wang Wenwen, Zhai Hongjun. Damage analysis of CDQ device and improvement of refractories. Naihuo Cailiao (Refractories, in Chinese), 2016, 50(5): 370-373. |

| [11] | Xu Guotao, Sheng Junbo, Lyu Yongjin, Chen Shengchun, Zhang Honglei, Li Hua, Liu Li. Damage investigation of inclined area of large CDQ ovens and their structure and refractories. Naihuo Cailiao (Refractories, in Chinese), 2016, 50(2): 125-129. |

| [1] | LYU Chunjiang, CHANG Cheng, HUANG Yifei, CAO Huiyan, LI Jie, ZHU Chong. Preparation and Properties of SiC Assembled Large Block for Blast Furnace Tuyeres [J]. China's Refractories, 2023, 32(4): 1-7. |

| [2] | CAO Huiyan, FENG Yanbin, ZHANG Xinhua, HUANG Zhigang, LI Jie, WANG Xinhui, WU Jiguang. Development and Application of Multi-phase Nitrides Bonded Silicon Carbide Lintel Blocks for Dry Quenching Furnaces [J]. China's Refractories, 2023, 32(2): 7-11. |

| [3] | WANG Jiaping, WU Jiguang, HUANG Zhigang, LYU Chunjiang, WANG Wenwu. Steam Oxidation Resistance Comparison of Several Silicon Carbide Refractories at Elevated Temperatures [J]. China's Refractories, 2023, 32(2): 18-23. |

| [4] | CAO Zhuang, JIA Qingwei, ZHANG Jun, ZHOU Huijun, LI Jinfeng, HUN Xianlei, YAN Leixin, QIN Hongbin, ZHANG Sanhua. Effect of Different Silica Fumes on Properties of Al2O3-SiC-C Castables for Iron Trough [J]. China's Refractories, 2023, 32(2): 31-36. |

| [5] | GU Chenwei, WANG Zhanmin, ZHAO Shixian, SI Yaochen, XIA Miao. Formation of Polytypoids (12H and 21R) in High Temperature Nitrogen Atmosphere and Their Effects on SiC-MgAl2O4 Composites [J]. China's Refractories, 2023, 32(2): 45-50. |

| [6] | XU Guotao, ZHAO Yuan, WU Jie, ZHANG Honglei, LIU Li, ZHANG Yanwen, ZHOU Wangzhi. Discussion on Abnormal Corrosion and Material Selection of Hot Iron Ladles with Steel Scrap Addition [J]. China's Refractories, 2023, 32(1): 1-5. |

| [7] | TIAN Xuekun, ZHOU Chaojie, ZHANG Lei, ZHAO Fei, JIA Quanli, LIU Xinhong, ZHONG Xiangchong. Preparation of ZrB2-ZrO2-SiC Composite Powder by Carbothermal Reduction from Zircon [J]. China's Refractories, 2023, 32(1): 25-29. |

| [8] | LIU Zhenglong, DENG Chengji, YU Chao, DING Jun, ZHU Hongxi. Effect of C@SiC Composite Powder Addition on Properties of Al2O3-SiC-C Castables for Iron Trough [J]. China's Refractories, 2022, 31(4): 39-44. |

| [9] | Valeriy V. MARTYNENKO, Vladimir V. PRIMACHENKO, Pavlo O. KUSHCHENKO, Irina G. SHULIK, Ludmyla K. SAVINA. Effects of a Combined Silica-containing Additive on Structural and Rheological Properties of a Low-cement Silicon Carbide Castable [J]. China's Refractories, 2022, 31(2): 1-6. |

| [10] | LUO Huaming, CAI Binli, YUAN Zhenqiang, ZUO Genliang, Zhang Jingzheng, WANG Fengyu, LI Jinyu, WEI Yingfeng, SUN Huochang, ZHAN Huasheng. Application and Hydration Resistance of SiC Refractories for Water-cooled Wall of Waste Incinerators [J]. China's Refractories, 2022, 31(2): 12-16. |

| [11] | SUN Saiyang, MA Xiaoqing, WANG Xingwei, ZHAO Yong, ZHANG Ronghui, FEI Weibao. Erosion Mechanism of Al2O3-SiC Castables for Lining Maintenance in Blast Furnace Hearths [J]. China's Refractories, 2022, 31(2): 17-23. |

| [12] | HAN Xiaoyuan, SHI Kai, XIA Yi, WANG Peixun, LIU Yang, SHANG Jianzhao. Effects of Three Silicon-based Raw Materials on Properties and Microstructure of MgO-Al-C Materials [J]. China's Refractories, 2021, 30(4): 30-35. |

| [13] | GUO Junhua, WANG Wenwu, CAO Huiyan, XU Haiyang. Fabrication and Pressureless Sintering of Silicon Carbide Refractories [J]. China's Refractories, 2021, 30(4): 40-44. |

| [14] | SHI Huiying, WANG Jiaping, WU Jiguang, HUANG Zhigang, QIN Hongbin. Steam Oxidation Resistance of Silicon Carbide Castables at Elevated Temperatures [J]. China's Refractories, 2021, 30(3): 23-27. |

| [15] | LIU Guoqi, LI Hongxia, YANG Wengang, QIAN Fan, YU Jianbin, MA Weikui. Design of Composite Ladle Shroud for Improving Thermal Shock Resistance [J]. China's Refractories, 2021, 30(1): 31-34. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||