China's Refractories ›› 2022, Vol. 31 ›› Issue (2): 1-6.DOI: 10.19691/j.cnki.1004-4493.2022.02.001

Effects of a Combined Silica-containing Additive on Structural and Rheological Properties of a Low-cement Silicon Carbide Castable

Valeriy V. MARTYNENKO*( ), Vladimir V. PRIMACHENKO, Pavlo O. KUSHCHENKO, Irina G. SHULIK, Ludmyla K. SAVINA

), Vladimir V. PRIMACHENKO, Pavlo O. KUSHCHENKO, Irina G. SHULIK, Ludmyla K. SAVINA

- The Ukrainian Research Institute of Refractories named after A.S. Berezhnoy, Kharkiv 61024, Ukraine

-

Online:2022-06-15Published:2022-07-05 -

Contact:Valeriy V. MARTYNENKO -

About author:Dr. Valeriy Martynenko is a director of the Ukrainian Research Institute of Refractories, named after very famous scientist in refractory field, academician A. S. Berezhnoy. He has been working in the institute for more than 40 years, carrying out researches in the field of silica, alumina, zirconia and chromia refractories, and their industrial applications. He has published over 370 scientific works and 80 patents. He is a member of the American Ceramic Society, as well as a member of the editorial board of the magazines “refractories WORLDFORUM” (Germany) and“China’s Refractories” (China). He is also the editor-in-chief of the collection “Scientific Research on Refractories and Technical Ceramics, Collection of Scientific Papers”, which is published by the institute.

Cite this article

Valeriy V. MARTYNENKO, Vladimir V. PRIMACHENKO, Pavlo O. KUSHCHENKO, Irina G. SHULIK, Ludmyla K. SAVINA. Effects of a Combined Silica-containing Additive on Structural and Rheological Properties of a Low-cement Silicon Carbide Castable[J]. China's Refractories, 2022, 31(2): 1-6.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2022.02.001

| Materials | LOI | Si | Al2O3 | SiO2 | Fe2O3/magnetic particles | СаО/ МgO | SiC/Сfree | Na2O/K2О |

|---|---|---|---|---|---|---|---|---|

| Silicon carbide | — | 0.40 | 0.04 | 0.43 | 0.20/0.03 | — | 98.40/0.20 | — |

| Alumina of the α-form | 0.02 | — | 99.75 | 0.02 | 0.01 | 0.01/No | — | Na2O+K2О 0.19 |

| Quartz-containing additive “A” | 0.13 | — | 0.42 | 99.36 | 0.04 | 0.04 | — | — |

| High-alumina cement | — | — | 73.80 | 1.20 | 0.33/No | 20.90/No | — | — |

| Silica-containing additive “F” | 10.30 | — | 18.80 | 66.50 | 0.10/No | 0.50/No | — | 3.50/0.23 |

| Silica-containing additive “S” | 4.80 | — | 24.40 | 68.30 | 0.08/No | 1.27/No | — | 0.75/0.22 |

Table 1 Chemical composition of raw materials /mass%

| Materials | LOI | Si | Al2O3 | SiO2 | Fe2O3/magnetic particles | СаО/ МgO | SiC/Сfree | Na2O/K2О |

|---|---|---|---|---|---|---|---|---|

| Silicon carbide | — | 0.40 | 0.04 | 0.43 | 0.20/0.03 | — | 98.40/0.20 | — |

| Alumina of the α-form | 0.02 | — | 99.75 | 0.02 | 0.01 | 0.01/No | — | Na2O+K2О 0.19 |

| Quartz-containing additive “A” | 0.13 | — | 0.42 | 99.36 | 0.04 | 0.04 | — | — |

| High-alumina cement | — | — | 73.80 | 1.20 | 0.33/No | 20.90/No | — | — |

| Silica-containing additive “F” | 10.30 | — | 18.80 | 66.50 | 0.10/No | 0.50/No | — | 3.50/0.23 |

| Silica-containing additive “S” | 4.80 | — | 24.40 | 68.30 | 0.08/No | 1.27/No | — | 0.75/0.22 |

| Materials | Particle size |

|---|---|

| Vibro-milled silicon carbide | The maximum particle size is 100 μm, the prevailing one is 8-40 μm. |

| Quartz-containing additive “A” | Angular particles of irregular shape, isometric and somewhat elongated. The maximum particle size is 130 μm, the prevailing one is < 4-30 μm. |

| Vibro-milled alumina of the α-form | The maximum particle size is 30 μm, the prevailing one is < 4-8 μm (particles ≤ 10 μm—not less than 90 %). |

| High-alumina cement | High-alumina cement aggregates are fine-crystalline (on average < 4-8 µm, single crystals—up to 20 µm). The maximum particle size is 100 μm, the prevailing one is < 4-30 μm. |

Table 2 Particle size of finely ground components

| Materials | Particle size |

|---|---|

| Vibro-milled silicon carbide | The maximum particle size is 100 μm, the prevailing one is 8-40 μm. |

| Quartz-containing additive “A” | Angular particles of irregular shape, isometric and somewhat elongated. The maximum particle size is 130 μm, the prevailing one is < 4-30 μm. |

| Vibro-milled alumina of the α-form | The maximum particle size is 30 μm, the prevailing one is < 4-8 μm (particles ≤ 10 μm—not less than 90 %). |

| High-alumina cement | High-alumina cement aggregates are fine-crystalline (on average < 4-8 µm, single crystals—up to 20 µm). The maximum particle size is 100 μm, the prevailing one is < 4-30 μm. |

| Components | Content of components in compositions /mass% | ||||

|---|---|---|---|---|---|

| 1(Base) | 2 | 3 | 4 | 5 | |

| Alumina of the α-form | 8 | 8.5 | 8 | 7.5 | 7 |

| Quartz-containing additive “A” | 2 | - | - | - | - |

| Mixture of dispersing additives (MDA) (above 100 %) | 0.2 | - | - | - | - |

| Silica-containing additive “F” | - | 1 | 1 | 1 | 1 |

| Silica-containing additive “S” | - | 0.5 | 1 | 1.5 | 2 |

Table 3 Composition of castables (Silicon carbide in all compositions—85 mass%, high alumina cement—5 mass%)

| Components | Content of components in compositions /mass% | ||||

|---|---|---|---|---|---|

| 1(Base) | 2 | 3 | 4 | 5 | |

| Alumina of the α-form | 8 | 8.5 | 8 | 7.5 | 7 |

| Quartz-containing additive “A” | 2 | - | - | - | - |

| Mixture of dispersing additives (MDA) (above 100 %) | 0.2 | - | - | - | - |

| Silica-containing additive “F” | - | 1 | 1 | 1 | 1 |

| Silica-containing additive “S” | - | 0.5 | 1 | 1.5 | 2 |

| Properties | Compositions | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Cold crushing strength after 7 days of hardening and drying at a temperature of 110 °C (2 h) /(N · mm-2) | 34.0 | 39.5 | 41.4 | 44.8 | 50.9 |

| Cold crushing strength after firing at 1 580 °C /(N · mm-2) | 145 | 152 | 160 | 120 | 111 |

| Apparent density /(g · cm-3) | 2.740 | 2.720 | 2.720 | 2.715 | 2.705 |

| Open porosity /% | 16.0 | 16.0 | 15.8 | 16.5 | 17.0 |

| Change in linear dimensions /% | -0.28 | -0.32 | -0.29 | -0.42 | -0.44 |

Table 4 Properties of samples from low-cement silicon carbide castables before and after heat treatment

| Properties | Compositions | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Cold crushing strength after 7 days of hardening and drying at a temperature of 110 °C (2 h) /(N · mm-2) | 34.0 | 39.5 | 41.4 | 44.8 | 50.9 |

| Cold crushing strength after firing at 1 580 °C /(N · mm-2) | 145 | 152 | 160 | 120 | 111 |

| Apparent density /(g · cm-3) | 2.740 | 2.720 | 2.720 | 2.715 | 2.705 |

| Open porosity /% | 16.0 | 16.0 | 15.8 | 16.5 | 17.0 |

| Change in linear dimensions /% | -0.28 | -0.32 | -0.29 | -0.42 | -0.44 |

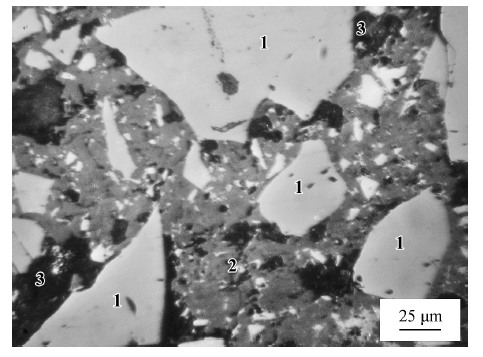

Fig. 4 Morphology of sample fracture surface of composition 3 (a) and spectra obtained from it, for chemical elements: carbon (b), silicon (c), calcium (d), oxygen (e) and aluminum (f)

| [1] | Semler Ch. E. Key issues for today’s refractories industry. Proceedings of the World Refractory Congress, Singapore, 2004: 1-10. |

| [2] | Silivanova A. N. Development of refractory concrete. New Refractories, 2009, 12: 52-54. |

| [3] |

L. M. Aksel’rod. Development of refractory production in the world and in Russia, new technologies. Refractories and Industrial Ceramics, 2011, 52(2): 95-106.

DOI URL |

| [4] | Tropinov A. M., Tropinova I. V. Experience of using thermal shock-resistant heat-resistant concrete in the furnaces of biofuel boilers. New Refractories, 2011, 11: 24-28. |

| [5] | Primachenko V. V., Babkina L. A., Savina L. K., Shcherbak L. M., Tinigin A. S., Tishina T. G. Sci. Proc. Investigation of the material composition effect on the properties of low-cement silicon carbide castable and samples from it. Coll. Sci. Proc. of PJSC “The URIR named after A. S. Berezhnoy”, Kharkiv, 2016, 116: 43-53. |

| [6] | ISO 1927-4: 2012 (E). Monolithic (unshaped) refractory products— Part 4: Determination of consistency of castables. Geneva, 2012: 8. |

| [7] | Rebinder P. A. Processes of structure formation in dispersed systems. Moscow: Stroyizdat Press, 1966: 212. |

| [8] | Primachenko V. V. Investigation of the formation processes of coagulation structures in vibrocasting coarse-grained thixotropic masses. Refractories, 1994, 5: 2-5. |

| [1] | ZANG Weinan, LUAN Jian, WANG Chunyan, MIAO Zhenhua, LI Jia, HAN Haopeng. Research Progress of Additives to Improve Hydration Resistance of Magnesia-calcium Materials [J]. China's Refractories, 2024, 33(1): 28-33. |

| [2] | Debasish CHANDRA. Comparison of Physico-mechanical Properties of TiO2 and Cr2O3 Additives on Reaction Sintered Zirconia-mullite Composites [J]. , 2019, 28(1): 11-21. |

| [3] | Valeriy V. MARTYNENKO*, Vladimir V. PRIMACHENKO, Irina G. SHULIK, Dmitriy A. SHISHKOVSKIY, Eleonora L. KARYAKINA, Vladimir V. VARGANOV. Advanced Ramming Mix Based on Fused Zirconia Stabilized by Combined Additives of CaO and MgO for Lining of Carbon Black Production Reactor [J]. , 2017, 26(3): 1-7. |

| [4] | GUO Weiming*,WU Lixiang,LIN Huatay, ZHANG Guojun. Review on Enhancement of Nitridation of Si Powder [J]. , 2015, 24(3): 18-21. |

| [5] | Christos G ANEZIRIS, V ROUNGOS, Steffen DUDCZIG, M EMMEL. Refractories with Improved Thermal Shock Performance Serving Low Carbon Economy [J]. , 2013, 22(3): 7-11. |

| [6] | SHI Huiying, ZHANG Yang, BU Xiangjuan. Effect of Treated Graphite on Properties of Al2O3-SiC-C Castables [J]. China's Refractories, 2009, 18(2): -. |

| [7] | PENG Xiaoyan, LI Lin, HE Zhiyong. Effect of Metal Additives on the Performance of Low-Carbon Magnesia-Carbon Materials [J]. China's Refractories, 2007, 16(1): -. |

| [8] | ZHOU Ningsheng, LIU Min, ZHANG Sanhua. Thermal Behavior in Relation to Different Bindings of Alumina Based Castables from 20 to 1000℃ [J]. China's Refractories, 2006, 15(4): -. |

| [9] | BU Jinglong,YU Zhidong,WANG Ruisheng. Effect of Sintering Additive on the Properties of Sialon-SiC by Gelcasting [J]. China's Refractories, 2004, 13(4): -. |

| [10] | ZHANG Yong, PENG Dayan,WEN Hongjie. Influence of Synthesized Super Al2O3 Powder on the Properties of Alumina Castable [J]. China's Refractories, 2003, 12(3): -. |

| [11] | ZHANG Minghua, FENG Yunkang. Hot Flowability and Hardening Time of Hot Self-flowing Repair Mixes [J]. China's Refractories, 2000, 9(1): -. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||