| [1] |

Deng Yong, Zhang Jianliang, Jiao Kexin. Economical and efficient protection for blast furnace hearth. ISIJ International, 2018, 58(7): 1198-1203.

DOI

URL

|

| [2] |

Bruno Vidal de Almeida, Elton Silva Neves, Sidiney Nascimento Silva, Fernando Vernilli Junior. Blast furnace hearth lining: Post mortem analysis. Materials Research, 2017, 20(3): 814-818.

DOI

URL

|

| [3] |

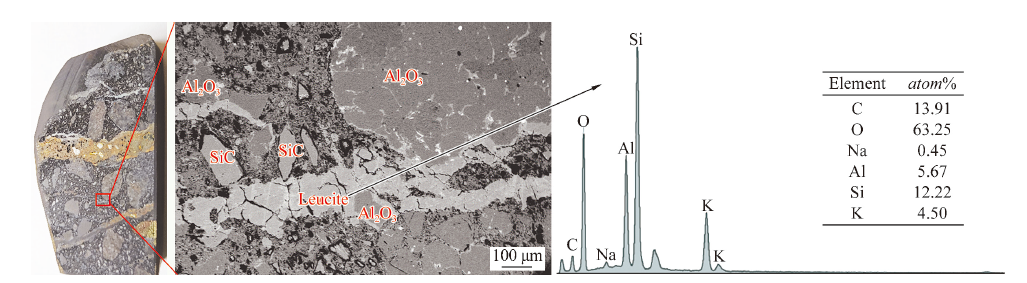

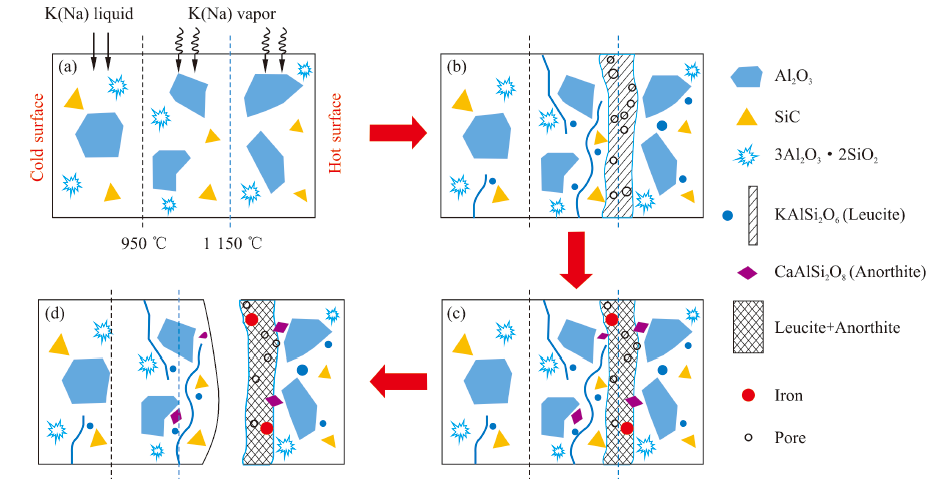

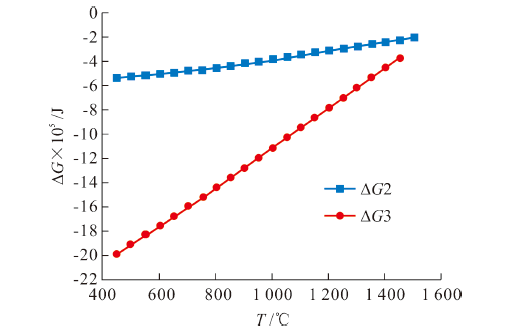

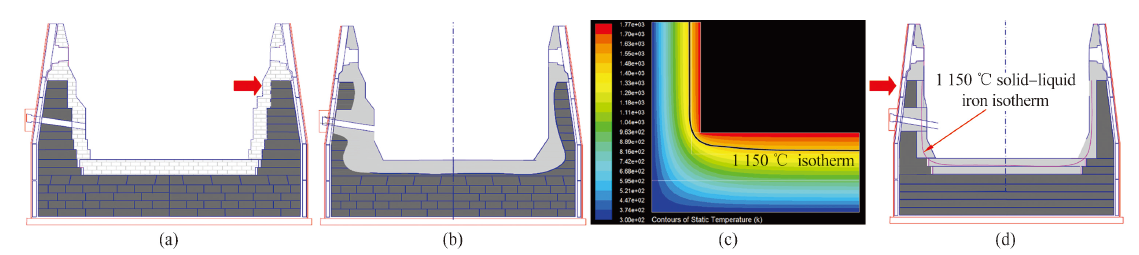

Jiao Kexin, Zhang Jianliang, Liu Zhengjian. Corrosion mechanism of carbon brick in the blast furnace hearth by potassium. Metallurgical Research & Technology, 2018, 115(1): 1-8.

|

| [4] |

Akihiko Shinotake, Hitoshi Nakamura, Nariyuki Yadoumaru, Yoshifumi Morizane, Masaru Meguro. Investigation of blast-furnace hearth sidewall erosion by core sample analysis and consideration of campaign operation. ISIJ International, 2003, 43(4): 321-330.

DOI

URL

|

| [5] |

S. N Silva., F. Vernilli, J. M. G.Lopes, S. M.Justus, E. Longo, J. B. Baldo, J. A. Varela. A methodology to investigate the wear of blast furnace hearth carbon refractory lining. Materials & Corrosion. 2013, 64(11): 1032-1038.

|

| [6] |

Niu Qun, Cheng Shusen, Xu Wenxuan, Niu Weijun. Microstructure and phase of carbon brick and protective layer of a 2 800 m3 industrial blast furnace hearth. ISIJ International, 2019, 59(10): 1776-1785.

DOI

|

| [7] |

Ziyu Guo, Jianliang Zhang, Kexin Jiao, Yaobing Zong, Zhongyi Wang. Occurrence state and behavior of carbon brick brittle in a large dissected blast furnace hearth. Steel Research International, 2021, 92(11): 2100273.

DOI

URL

|

| [8] |

Qiao Wan, Nie Jianhua, Qiu Wendong, Wang Lihui, Yin Yucheng, Liang Yonghe, Yin Guoheng. Effect of solid content of silica sol on properties of Al2O3-SiC castables. Naihuo Cailiao (Refractories, in Chinese), 2014, 48(1): 39-42.

|

| [9] |

Xiaoyue Fan, Kexin Jiao, Jianliang Zhang, Ruiqi Cao, Rusheng He, Kaidi Wang. Study on physicochemical properties of Al2O3-SiC-C castable for blast furnace. Ceramics International, 2019, 45(11): 13903-13911.

DOI

|

| [10] |

Haibin Zuo, Cong Wang, Yingli Liu. Dissolution behavior of a novel Al2O3-SiC-SiO2-C composite refractory in blast furnace slag. Ceramics International, 2017, 43(9): 7080-7087.

DOI

URL

|

| [11] |

Tang Xunhai, Li Honghui, Yin Qiong, Fan Yonglian, Zhang Wenwen. Studies and application of silica sol bonded self-flow castables. Proceedings of the 7th International Symposium on Refractories, Xi’an, China, 2016: 1-6.

|

| [12] |

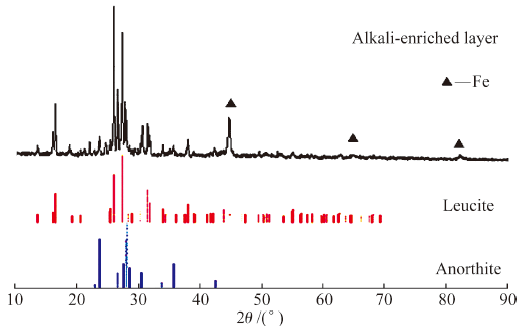

Toshitaka Ota, Minoru Takahashi, Iwao Yamai, Hisao Suzuki. High-thermal-expansion polycrystalline leucite ceramic. Journal of the American Ceramic Society, 1993, 76(9): 2379-2381.

DOI

URL

|

), MA Xiaoqing1, WANG Xingwei2, ZHAO Yong2, ZHANG Ronghui1, FEI Weibao3

), MA Xiaoqing1, WANG Xingwei2, ZHAO Yong2, ZHANG Ronghui1, FEI Weibao3