| [1] |

ZHANG Keke, QIN Feng, YAN Miaoxin, LIU Shijie, LI Xuhao, GUO Yusen, WANG Li, YIN Chaofan, DONG Binbin.

Progress in Preparation Technology of Porous Ceramics for High Temperature Dust Filtration

[J]. China's Refractories, 2023, 32(4): 42-51.

|

| [2] |

FAN Muxu, HOU Xiaojing, FENG Zhiyuan, WANG Han, LIU Pengcheng, SHI Gan.

Alkali Vapor Corrosion of Different Refractories at High Temperatures

[J]. China's Refractories, 2023, 32(2): 24-30.

|

| [3] |

GAO Jinxing, XU Lingling, LI Liya, MU Jinghua, LI Xiaokai, XU Enxia, GUO Donghui, MENG Dekang, ZHOU Gaofeng, CHEN Shoujie.

Effect of Y2O3 Addition on Preparation and Properties of β-SiAlON Reticular Porous Ceramic Filters

[J]. China's Refractories, 2022, 31(4): 28-33.

|

| [4] |

JIAO Changfa, LI Guohua, KANG Chi.

Preparation of Magnesia Insulation Materials by Walnut Shell Powder Impregnated with Silica Sol

[J]. China's Refractories, 2022, 31(3): 34-37.

|

| [5] |

YAN Mingwei, LIU Kaiqi, ZHANG Jiayu, SUN Guangchao, LI Xiang, SI Kaikai.

Research Progress on Thermal Shock Behavior of Porous Ceramics

[J]. China's Refractories, 2022, 31(1): 24-29.

|

| [6] |

WANG Tao, WANG Bo, HOU Baoqiang, SHI Zhongqi, YANG Jun, XIA Hongyan, WANG Jiping, WANG Hongjie, YANG Jianfeng.

Preparation and Application Progress of Porous Alumina

[J]. China's Refractories, 2020, 29(4): 10-18.

|

| [7] |

SU Chang, MA Beiyue, REN Xinming, LIU Guoqiang, ZHU Qiang.

Effect of Starch Addition on Properties of Corundum-mullite Porous Ceramics

[J]. China's Refractories, 2020, 29(4): 19-22.

|

| [8] |

LI Fei, LIU Jixuan, ZHANG Guojun.

Porous Ultra-high Temperature Ceramics for Ultra-high Temperature Thermal Protection System

[J]. China's Refractories, 2020, 29(4): 23-28.

|

| [9] |

Lei HAN, Haijun ZHANG, Shaowei ZHANG.

Preparation of Si3N4 Porous Ceramics via Combined Foam-gelcasting and Catalytic Nitridation with Fe Powder as Catalyst

[J]. China's Refractories, 2020, 29(3): 1-6.

|

| [10] |

LAO Dong, JIA Wenbao, WANG Yufan, CHEN Ruoyu, LI Shujing, HEI Daqian, WANG Zhonghua, DING Yue, ZHANG Wenhao, LIU Meiqi.

Fabrication and Properties of Alumina-based Reticulated Porous Ceramics

[J]. China's Refractories, 2020, 29(2): 31-36.

|

| [11] |

ZHENG Han, LI Wei, DU Jiaolong, LI Hongxia, LIU Guoqi, CHEN Zihao, CHEN Yongqiang.

Preparation and Properties of Si2N2O Ceramics for Microwave Sintering Furnaces

[J]. China's Refractories, 2020, 29(2): 42-46.

|

| [12] |

ZHANG Yaran, MA Beiyue, YU Jingyu, SU Chang, REN Xinming, QIAN Fan, LIU Guoqi, LI Hongxia, YU Jingkun.

Preparation of SiC Porous Ceramics by Crystalline Silicon Cutting Waste

[J]. , 2018, 27(4): 46-50.

|

| [13] |

REN Xinming, MA Beiyue, SU Chang, YU Jingyu, ZHANG Yaran.

Effect of Main Material Ratio on Properties of SiC-Al2O3 Porous Ceramics via Polymeric Replication Method

[J]. , 2018, 27(3): 44-47.

|

| [14] |

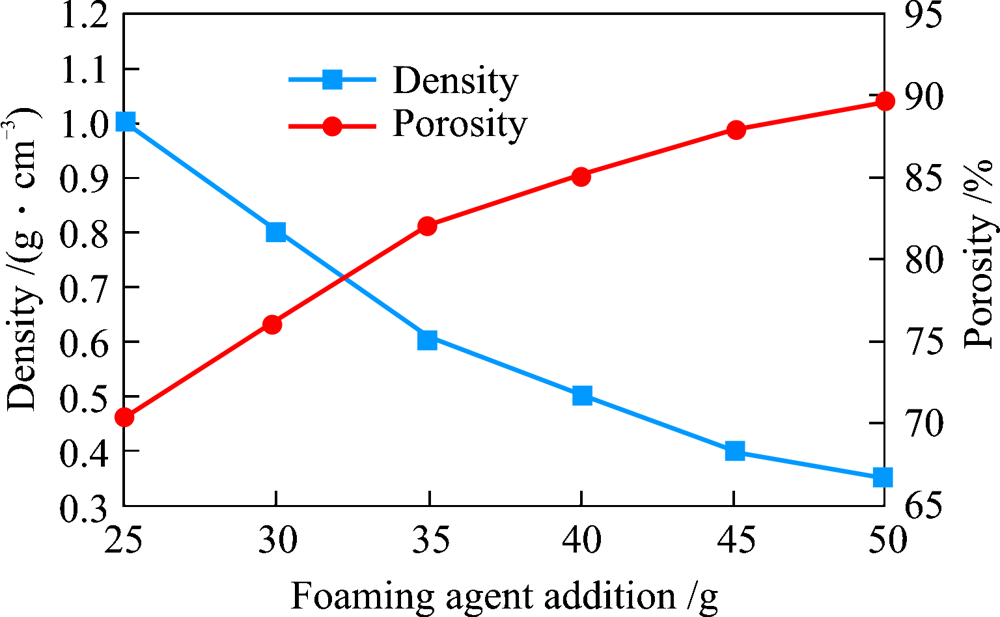

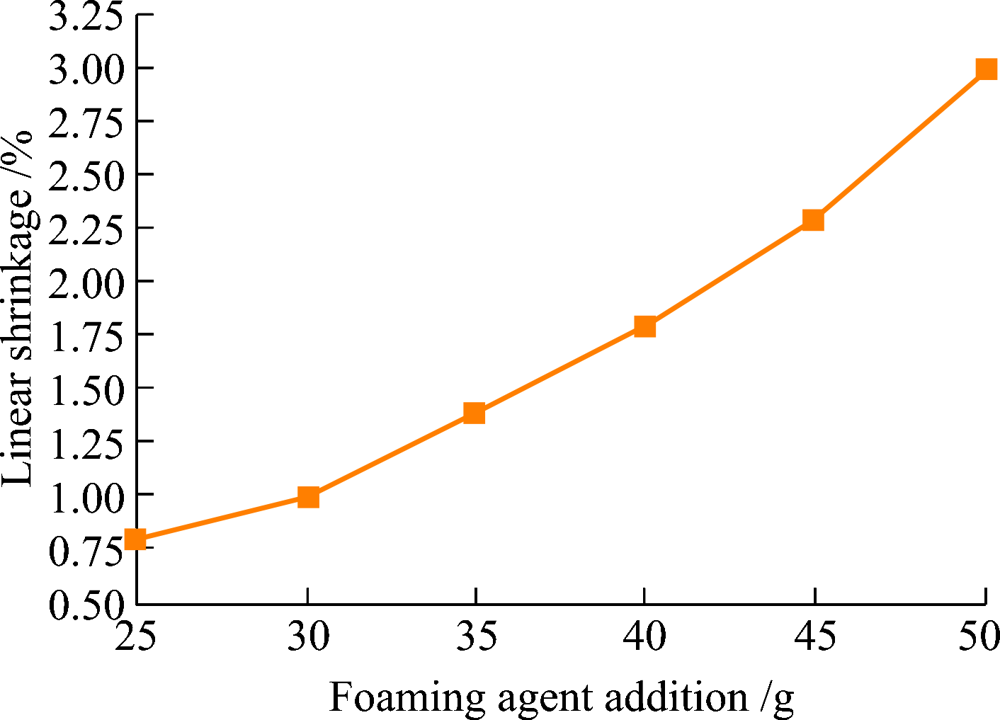

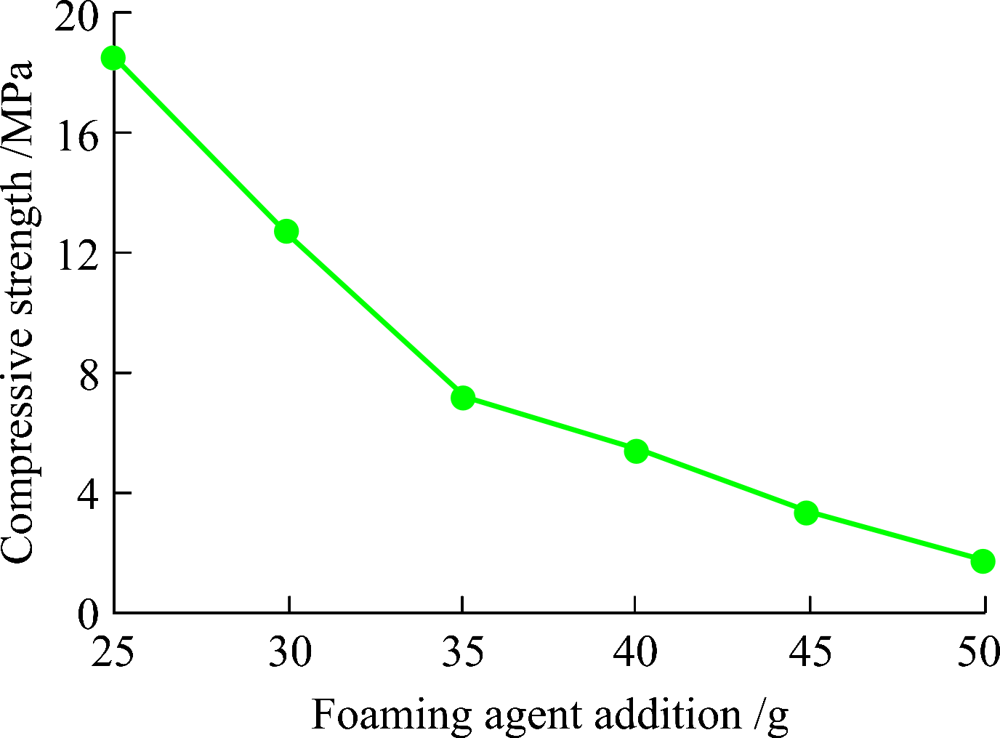

WANG Gang*,YUAN Bo,WU Haibo, DONG Binbin, HAN Jianshen, CHEN Kuo, LI Hongxia.

Preparation and Properties of Alumina Heat Insulation Materials with High Purity

[J]. , 2015, 24(4): 18-22.

|

| [15] |

YUAN Bo*,CHEN Kuo,HAN Jianshen, DONG Binbin, WANG Gang, LI Hongxia.

Thermal Insulation Materials of Alumina Based Porous Ceramics

[J]. , 2015, 24(3): 29-33.

|

), ZHANG Qi, HAN Jianshen, YUAN Bo, LI Hongxia

), ZHANG Qi, HAN Jianshen, YUAN Bo, LI Hongxia