China's Refractories ›› 2020, Vol. 29 ›› Issue (4): 23-28.DOI: 10.19691/j.cnki.1004-4493.2020.04.005

• Original article • Previous Articles Next Articles

Porous Ultra-high Temperature Ceramics for Ultra-high Temperature Thermal Protection System

LI Fei, LIU Jixuan, ZHANG Guojun*( )

)

- State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, College of Materials Science and Engineering, Institute of Functional Materials, Donghua University, Shanghai 201620, China

-

Online:2020-12-15Published:2020-12-15 -

Contact:ZHANG Guojun -

About author:Li Fei received his Ph.D. in materials physics and chemistry from Shanghai Institute of Ceramics Chinese Academy of Sciences (SICCAS) in 2015. After that he worked as an assistant professor in SICCAS until 2018. Then he joined Prof. Guojun Zhang’s group at Donghua University. He is a specially appointed researcher at Osaka University from December 2020. His research focuses on the design, preparation and characterization of high-entropy materials and porous ceramics.

Cite this article

LI Fei, LIU Jixuan, ZHANG Guojun. Porous Ultra-high Temperature Ceramics for Ultra-high Temperature Thermal Protection System[J]. China's Refractories, 2020, 29(4): 23-28.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2020.04.005

Fig. 1 (a) Photograph of the crew capsule launched as payload on China’s Long March 5B rocket after re-entry (note charring on surface insulative materials) (b) Artist’s illustration of the Space Shuttle Orbiter thermal protection system[5] (c) Phenolic impregnated carbon ablator (PICA) (d) Photograph of high-temperature reusable surface insulation tile

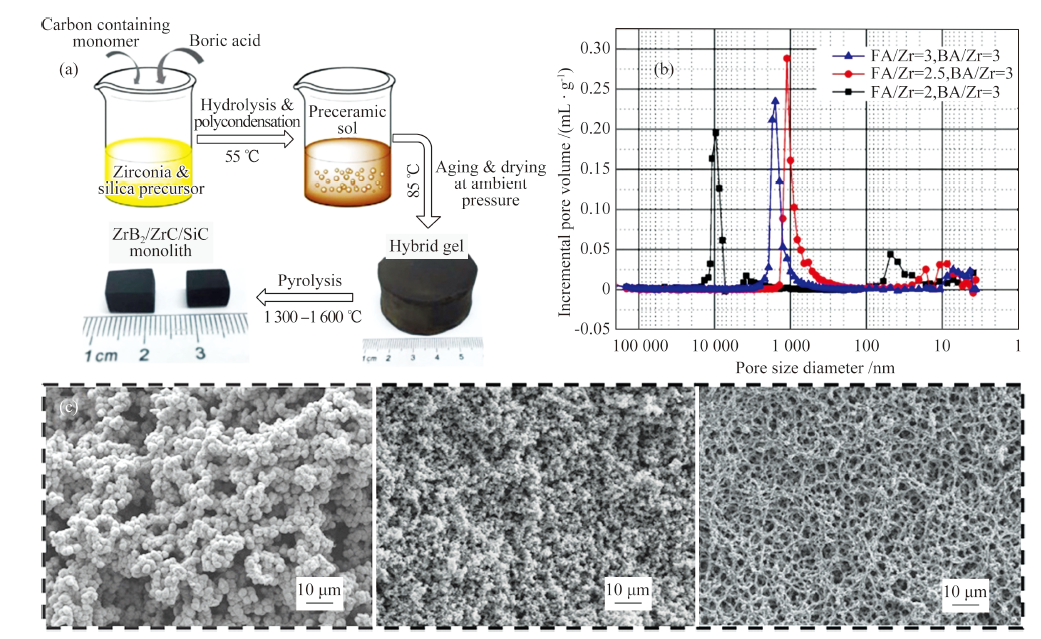

Fig. 4 (a) Schematic illustration for synthesis of porous UHTCs via sol-gel approaches (b) Pore size distribution of porous UHTCs (c) Tailorable microstructures of porous UHTCs[18, 21]

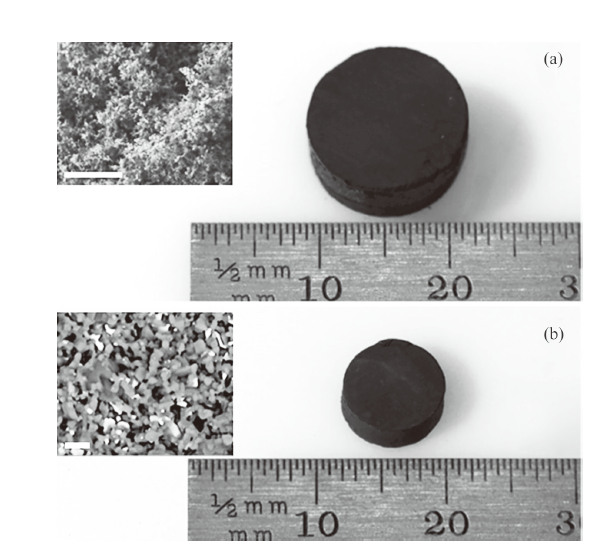

Fig. 6 ZrB2 aerogel as-synthesized (a) and after 30 min at 2 000 °C in an inert atmosphere (b) Inset: SEM images of the corresponding grain structure, scale bar =5 μm[17]

| [1] | https://spacenews.com/long-march-5b-launch-clears-path-for-chinese-space-station-project |

| [2] | Frances I. Hurwitz. Thermal Protection Systems (TPSs), Encyclopedia of Aerospace Engineering, John Wiley & Sons, 2010. |

| [3] | Padture, Nitin P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8): 804-809. |

| [4] | Safety of the thermal protection system of the space shuttle orbiter: quantitative analysis and organizational factors, http://spaceflight.nasa.gov/shuttle/archives/sts-107/investigation/tps_safety.pdf |

| [5] | Gail Chapline, Alvaro Rodriguez, Cooper Snapp, Myron Pession, Paul Bauer. Thermal protection systems, Engineering Inonvation 182-199. https://www.nasa.gov/centers/johnson/pdf/584728main_Wings-ch4b-pgs182-199.pdf |

| [6] | Guojun Zhang, Dewei Ni, Ji Zou, Haitao Liu, Wenwen Wu, Jixuan Liu, Tohru S. Suzuki, Yoshio Sakka. Inherent anisotropy in transition metal diborides and microstructure/property tailoring in ultra-high temperature ceramics—A review. Journal of the European Ceramic Society, 2018, 38(2): 371-389. |

| [7] | M.S. Liang, F. Li, X.F. Ma, Z. Kang, X. Huang, X.-G. Wang, G.-J. Zhang. Syntheses of ZrC-SiC nanopowder via sol-gel method. Ceramics International, 2016, 42(1): 1345-1351. |

| [8] | LI Fei, Liu Jixuan, Huang Xiao, Zhang Guojun. Porous ultra-high temperature ceramics: preparation, structure and properties. Journal of the Chinese Ceramic Society (in Chinese), 2018, 46(12): 1669-1684. |

| [9] | Xinxin Jin, Xinghong Zhang, Jiecai Han, Ping Hu, Rujie He. Thermal shock behavior of porous ZrB2-SiC ceramics. Materials Science & Engineering A, 2013, 588: 175-180. |

| [10] | Xinxin Jin, Limin Dong, Huanyan Xu, Lizhu Liu, Ning Li, Xinghong Zhang, Jiecai Han. Effects of porosity and pore size on mechanical and thermal properties as well as thermal shock fracture resistance of porous ZrB2-SiC ceramics. Ceramics International, 2016, 42(7): 9051-9057. |

| [11] | Xinxin Jin, Limin Dong, Qin Li, Hui Tang, Ning Li, Qiang Qu. Thermal shock cracking of porous ZrB2-SiC ceramics. Ceramics International, 2016, 42(11): 13309-13313. |

| [12] | William G, Fahrenholtz, Eric G, Wuchina, William E. Lee, Yanchun Zhou. Ultra-high temperature ceramics: materials for extreme environment applications. John Wiley & Sons, Hoboken, New Jersey, 2014: 416-436. |

| [13] | Silvia Leo, Laura Jukes, Samuel Pinches, Carolina Tallon, George Franks. Freeze casting for near-net-shaping of dense zirconium diboride ceramics. Journal of the American Ceramic Society, 2018, 101(7): 2770-2785. |

| [14] | Fei Li, Xiao Huang, Fei Li, Guojun Zhang. Preparation of Ultra-High Temperature Ceramics-based Materials by Sol-gel Routes//Usha Chandra. Recent Applications in Sol-Gel Synthesis. 2017: Chapter 03. |

| [15] | C. R. Rambo, J. Cao, O. Rusina, H. Sieber. Manufacturing of biomorphic (Si, Ti, Zr)-carbide ceramics by sol-gel processing. Carbon, 2005, 43(6): 1174-1183. |

| [16] | Fei Li, Zhuang Kang, Xiao Huang, Xingang Wang, Guojun Zhang. Preparation of zirconium carbide foam by direct foaming method. Journal of the European Ceramic Society, 2014, 34(15): 3513-3520. |

| [17] | James T, Cahill, Sally Turner, Jianchao Ye, Brian Shevitski, Shaul Aloni, Theodore F, Baumann, Alex Zettl, Joshua D, Kuntz, Marcus A. Ultrahigh-temperature ceramic aerogels. Chemistry of Materials, 2019, 31(10): 3700-3704. |

| [18] | Fei Li, Xiao Huang. Preparation of highly porous ZrB2/ZrC/SiC composite monoliths using liquid precursors via direct drying process. Journal of the European Ceramic Society, 2018, 38(4): 1103-1111. |

| [19] | Fei Li, Xingang Wang, Xiao Huang, Jixuan Liu, Weichao Bao, Guojun Zhang, Hongzhi Wang. Preparation of ZrC/SiC porous self-supporting monoliths via sol-gel process using polyethylene glycol as phase separation inducer. Journal of the European Ceramic Society, 2018, 38(14): 4806-4813. |

| [20] | Fei Li, Jixuan Liu, Xiao Huang, Weichao Bao, Guojun Zhang, Hongzhi Wang. Carbothermal conversion of self-supporting organic/inorganic interpenetrating networks to porous metal boride monoliths. Journal of the American Ceramic Society, 2019, 102(10): 5746-5762. |

| [21] | Fei Li, Xiao Huang, Jixuan Liu, Guojun Zhang. Sol-gel derived porous ultra-high temperature ceramics. Journal of Advanced Ceramics, 2020(9): 1-16. |

| [1] | ZHANG Keke, QIN Feng, YAN Miaoxin, LIU Shijie, LI Xuhao, GUO Yusen, WANG Li, YIN Chaofan, DONG Binbin. Progress in Preparation Technology of Porous Ceramics for High Temperature Dust Filtration [J]. China's Refractories, 2023, 32(4): 42-51. |

| [2] | GAO Jinxing, XU Lingling, LI Liya, MU Jinghua, LI Xiaokai, XU Enxia, GUO Donghui, MENG Dekang, ZHOU Gaofeng, CHEN Shoujie. Effect of Y2O3 Addition on Preparation and Properties of β-SiAlON Reticular Porous Ceramic Filters [J]. China's Refractories, 2022, 31(4): 28-33. |

| [3] | YAN Mingwei, LIU Kaiqi, ZHANG Jiayu, SUN Guangchao, LI Xiang, SI Kaikai. Research Progress on Thermal Shock Behavior of Porous Ceramics [J]. China's Refractories, 2022, 31(1): 24-29. |

| [4] | WANG Tao, WANG Bo, HOU Baoqiang, SHI Zhongqi, YANG Jun, XIA Hongyan, WANG Jiping, WANG Hongjie, YANG Jianfeng. Preparation and Application Progress of Porous Alumina [J]. China's Refractories, 2020, 29(4): 10-18. |

| [5] | SU Chang, MA Beiyue, REN Xinming, LIU Guoqiang, ZHU Qiang. Effect of Starch Addition on Properties of Corundum-mullite Porous Ceramics [J]. China's Refractories, 2020, 29(4): 19-22. |

| [6] | Lei HAN, Haijun ZHANG, Shaowei ZHANG. Preparation of Si3N4 Porous Ceramics via Combined Foam-gelcasting and Catalytic Nitridation with Fe Powder as Catalyst [J]. China's Refractories, 2020, 29(3): 1-6. |

| [7] | LAO Dong, JIA Wenbao, WANG Yufan, CHEN Ruoyu, LI Shujing, HEI Daqian, WANG Zhonghua, DING Yue, ZHANG Wenhao, LIU Meiqi. Fabrication and Properties of Alumina-based Reticulated Porous Ceramics [J]. China's Refractories, 2020, 29(2): 31-36. |

| [8] | ZHENG Han, LI Wei, DU Jiaolong, LI Hongxia, LIU Guoqi, CHEN Zihao, CHEN Yongqiang. Preparation and Properties of Si2N2O Ceramics for Microwave Sintering Furnaces [J]. China's Refractories, 2020, 29(2): 42-46. |

| [9] | WANG Gang, ZHANG Qi, HAN Jianshen, YUAN Bo, LI Hongxia. Preparation and Properties of Calcium Hexaaluminate Porous Ceramics [J]. China's Refractories, 2020, 29(1): 15-19. |

| [10] | ZHANG Yaran, MA Beiyue, YU Jingyu, SU Chang, REN Xinming, QIAN Fan, LIU Guoqi, LI Hongxia, YU Jingkun. Preparation of SiC Porous Ceramics by Crystalline Silicon Cutting Waste [J]. , 2018, 27(4): 46-50. |

| [11] | REN Xinming, MA Beiyue, SU Chang, YU Jingyu, ZHANG Yaran. Effect of Main Material Ratio on Properties of SiC-Al2O3 Porous Ceramics via Polymeric Replication Method [J]. , 2018, 27(3): 44-47. |

| [12] | WANG Gang*,YUAN Bo,WU Haibo, DONG Binbin, HAN Jianshen, CHEN Kuo, LI Hongxia. Preparation and Properties of Alumina Heat Insulation Materials with High Purity [J]. , 2015, 24(4): 18-22. |

| [13] | YUAN Bo*,CHEN Kuo,HAN Jianshen, DONG Binbin, WANG Gang, LI Hongxia. Thermal Insulation Materials of Alumina Based Porous Ceramics [J]. , 2015, 24(3): 29-33. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||