China's Refractories ›› 2020, Vol. 29 ›› Issue (2): 6-10.DOI: 10.19691/j.cnki.1004-4493.2020.02.002

• Original article • Previous Articles Next Articles

Application Performance of Microporous Sintered Alumina in Alumina Magnesia Castables for Ladles

HE Jian, LYU Xusheng*( ), ZHANG Jialiang, ZHOU Wei, LI Yin

), ZHANG Jialiang, ZHOU Wei, LI Yin

- Jiangsu Jingxin New Materials Co., Ltd., Yangzhou 225264, China

-

Revised:2021-05-13Online:2020-06-15Published:2020-06-15 -

Contact:LYU Xusheng -

About author:He Jian, born in 1983, finished his junior college education from Fuzhou Command College of The Chinese People's Armed Police Forces in 2006. He has been the general manager of Jiangsu Jingxin New Materials Co., Ltd. since 2015. He won many prizes such as Jiangdu District Chief Quality Award in 2014, Yangzhou City Mayor Quality Award in 2015, Top Ten Young Entrepreneurship Stars in Jiangdu District in 2016, and Advanced Quality Individuals in Jiangdu District in 2017.

Cite this article

HE Jian, LYU Xusheng, ZHANG Jialiang, ZHOU Wei, LI Yin. Application Performance of Microporous Sintered Alumina in Alumina Magnesia Castables for Ladles[J]. China's Refractories, 2020, 29(2): 6-10.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2020.02.002

| Samples | Al2O3 /mass% | Bulk density /(g · cm-3) | Apparent porosity /% | Closed porosity /% | Water absorption /% |

|---|---|---|---|---|---|

| Common sintered alumina | 99.3 | 3.55 | 3.6 | 6.5 | 1.02 |

| Microporous sintered alumina | 99.2 | 3.50 | 3.8 | 7.6 | 1.09 |

Table 1 Physical and chemical properties

| Samples | Al2O3 /mass% | Bulk density /(g · cm-3) | Apparent porosity /% | Closed porosity /% | Water absorption /% |

|---|---|---|---|---|---|

| Common sintered alumina | 99.3 | 3.55 | 3.6 | 6.5 | 1.02 |

| Microporous sintered alumina | 99.2 | 3.50 | 3.8 | 7.6 | 1.09 |

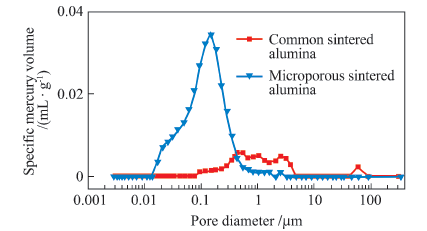

| Samples | 25 ℃ | 300 ℃ | 500 ℃ | 800 ℃ |

|---|---|---|---|---|

| Common sintered alumina | 26.114 | 12.759 | 9.202 | 7.896 |

| Microporous sintered alumina | 25.851 | 9.725 | 5.604 | 4.864 |

Table 2 Thermal conductivity of two kinds of alumina at different temperatures /(W · m-1 · K-1)

| Samples | 25 ℃ | 300 ℃ | 500 ℃ | 800 ℃ |

|---|---|---|---|---|

| Common sintered alumina | 26.114 | 12.759 | 9.202 | 7.896 |

| Microporous sintered alumina | 25.851 | 9.725 | 5.604 | 4.864 |

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | MnO |

|---|---|---|---|---|---|

| 11.23 | 2.43 | 46.84 | 9.24 | 27.87 | 2.38 |

Table 3 Chemical composition of slag /mass%

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | MnO |

|---|---|---|---|---|---|

| 11.23 | 2.43 | 46.84 | 9.24 | 27.87 | 2.38 |

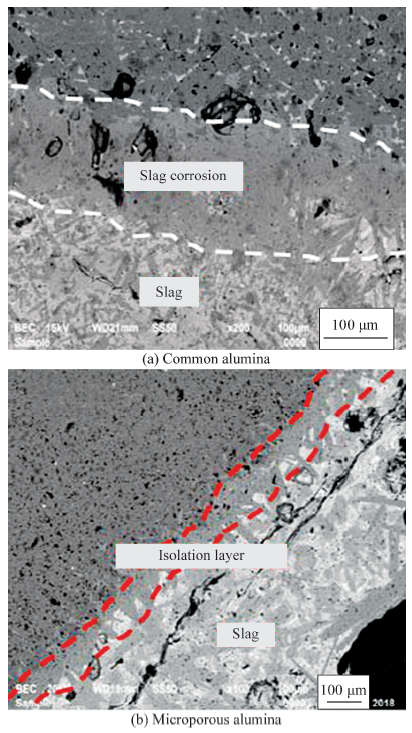

| Elements | Ca | Al | Fe | O |

|---|---|---|---|---|

| Contents | 4.91 | 46.12 | 2.69 | 46.28 |

Table 4 EDS results of isolation layer /mass%

| Elements | Ca | Al | Fe | O |

|---|---|---|---|---|

| Contents | 4.91 | 46.12 | 2.69 | 46.28 |

| Castables | Refrac-toriness under load, T0.6 /℃ | Hot modulus of rupture /MPa | Retention ratio of MOR after 5 thermal shock cycles /% | Thermal conductivity at 800 ℃ / (W·m-1·K-1) |

|---|---|---|---|---|

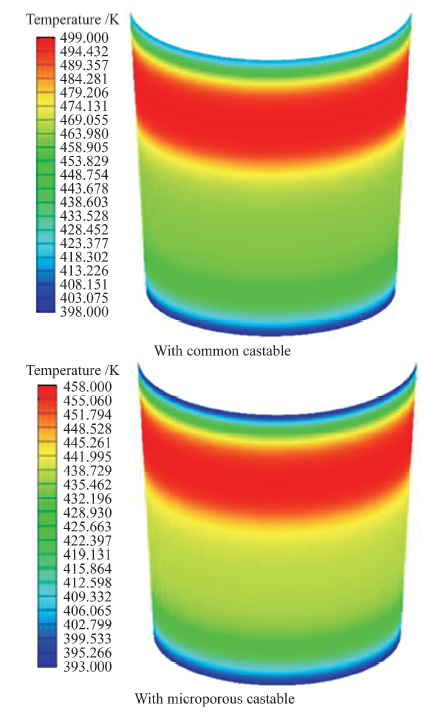

| Common castable | 1 520 | 8.32 | 18.10 | 0.93 |

| Microporous castable | 1 518 | 8.24 | 22.57 | 0.79 |

Table 5 High temperature properties comparison of two castables

| Castables | Refrac-toriness under load, T0.6 /℃ | Hot modulus of rupture /MPa | Retention ratio of MOR after 5 thermal shock cycles /% | Thermal conductivity at 800 ℃ / (W·m-1·K-1) |

|---|---|---|---|---|

| Common castable | 1 520 | 8.32 | 18.10 | 0.93 |

| Microporous castable | 1 518 | 8.24 | 22.57 | 0.79 |

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | MnO | P2O5 |

|---|---|---|---|---|---|---|

| 15.51 | 2.07 | 34.75 | 7.12 | 31.10 | 2.38 | 2.00 |

Table 6 Chemical composition of converter final slag /mass%

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | MnO | P2O5 |

|---|---|---|---|---|---|---|

| 15.51 | 2.07 | 34.75 | 7.12 | 31.10 | 2.38 | 2.00 |

| Castables | Corrosion ratio /% | Penetration ratio /% |

|---|---|---|

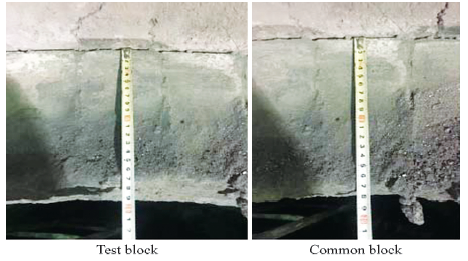

| Common castable | 31.1 | 60.4 |

| Microporous castable | 9.5 | 55.3 |

Table 7 Corrosion and penetration of castables

| Castables | Corrosion ratio /% | Penetration ratio /% |

|---|---|---|

| Common castable | 31.1 | 60.4 |

| Microporous castable | 9.5 | 55.3 |

| [1] |

Lvping Fu, Huazhi Gu, Ao Huang, Hongwei Ni. Correlations among processing parameters and porosity of a lightweight alumina. Ceramics International, 2018,44(12):14076-14081.

DOI URL |

| [2] |

Yalou Xin, Hongfeng Yin, Yun Tang, Qifa Wan, Kui Gao, Hudie Yuan, Zhiwei Wang. Formation mechanism and characterization of gradient density in corundum-spinel refractory. Ceramics International, 2019,45(6):8023-8026.

DOI URL |

| [3] | Guiyuan Wu, Wen Yan, Stefan Schafföner, Yajie Dai, Bingqiang Han, Tianqing Li, Sanbao Ma, Nan Li, Guangqiang Li. A comparative study on the microstructures and mechanical properties of a dense and a lightweight magnesia refractories. Journal of Alloys and Compounds, 2019(796):131-137. |

| [4] | Huan Chen, Lei Zhao, Xuan He, Wei Fang, Zhongxing Lei, Hui Chen. The fabrication of porous corundum spheres with core-shell structure for corundum-spinel castables. Materials & Design, 2015(85):574-581. |

| [5] |

Wen Yan, Guiyuan Wu, Sanbao Ma, Stefan Schafföner, Yajie Dai, Zhe Chen, Jiangtao Qi, Nan Li. Energy efficient lightweight periclase-magnesium alumina spinel castables containing porous aggregates for the working lining of steel ladles. Journal of the European Ceramic Society, 2018,38(12):4276-4282.

DOI URL |

| [6] |

Lvping Fu, Huazhi Gu, Ao Huang, Yongshun Zou, Meijie Zhang. Fabrication of lightweight alumina with nanoscale intracrystalline pores. Journal of the American Ceramic Society, 2020,103(3):2262-2271.

DOI PMID |

| [7] | Lvping Fu, Huazhi Gu, Ao Huang, Yongshun Zou, Hongwei Ni. Enhanced corrosion resistance through the introduction of fine pores: Role of nano-sized intracrystalline pores. Corrosion Science, 2019(161):108-182. |

| [1] | Yunpeng ZHOU, Wang FENG, Shankha CHATTERJEE, Andus BUHR, Sebastian KLAUS. Study on Chrome-free Purging Plugs for Steel Ladles [J]. China's Refractories, 2024, 33(2): 41-47. |

| [2] | DU Juan, GUO Huishi, YANG Jialin, LI Wenfeng, GUI Yanghai, ZHAO Zhiqiang, LIU Yingfan. Effects of Al2O3-SiO2 Raw Material Types on Properties of Anorthite Based Insulation Refractories [J]. China's Refractories, 2024, 33(1): 23-27. |

| [3] | JIN Zhishang, SHAN Zhilin, ZHAO Huizhong, YU Jun, ZHANG Han. Effect of Porogenic Agents on Properties of Microporous Mullite Aggregates [J]. China's Refractories, 2023, 32(3): 31-35. |

| [4] | GUO Peng, CHEN Lu, YU Tongshu, ZHANG Hui, WANG Dongdong. Effect of Zirconia Corundum Addition on Properties of Chrome Corundum Castables [J]. China's Refractories, 2023, 32(2): 41-44. |

| [5] | WANG Zhiqiang, LEI Zhongxing, XU Guotao, PENG Xiaoqian, ZHU Boquan, LIU Li, GUO Zongqi. Fabrication and Improving Properties of Lightweight Al2O3-MgO Castables for Ladle Working Lining [J]. China's Refractories, 2023, 32(1): 6-13. |

| [6] | LI Yanjing, SUN Jialin, LI Yong, KANG Jian, MA Shulong, MA Fei, ZHANG Jili. Influence of Flotation Magnesia Particles and Al2O3 Fines on Properties of Periclase-spinel Bricks [J]. China's Refractories, 2022, 31(4): 12-15. |

| [7] | LIU Zhenglong, DENG Chengji, YU Chao, DING Jun, ZHU Hongxi. Effect of C@SiC Composite Powder Addition on Properties of Al2O3-SiC-C Castables for Iron Trough [J]. China's Refractories, 2022, 31(4): 39-44. |

| [8] | HAO Xian, LIU Guoqi, LI Zhixing, XU Chaojie, ZHANG Jianwei, LI Yong, LI Hongyu, LI Hongxia, FU Baoquan. Effect of Al-Si Alloy Addition on Properties of Fused Spinel Carbon Materials [J]. China's Refractories, 2022, 31(4): 45-52. |

| [9] | ZHU Shaojun. Damage Mechanism and Countermeasures of Al2O3-SiC-C Refractories Under Extreme Conditions [J]. China's Refractories, 2022, 31(2): 7-11. |

| [10] | YAN Mingwei, LIU Kaiqi, ZHANG Jiayu, SUN Guangchao, LI Xiang, SI Kaikai. Research Progress on Thermal Shock Behavior of Porous Ceramics [J]. China's Refractories, 2022, 31(1): 24-29. |

| [11] | SUN Yang, ZHANG Xiuhua, HU Hao, LIU Xiang, LIU Ying, CHEN Bo. Performance of High Thermal Conductivity Dense Silica Bricks and Their High Thermal Conductivity Mechanism [J]. China's Refractories, 2022, 31(1): 30-34. |

| [12] | HAN Xiaoyuan, SHI Kai, XIA Yi, WANG Peixun, LIU Yang, SHANG Jianzhao. Effects of Three Silicon-based Raw Materials on Properties and Microstructure of MgO-Al-C Materials [J]. China's Refractories, 2021, 30(4): 30-35. |

| [13] | LIU Guoqi, LI Hongxia, YANG Wengang, QIAN Fan, YU Jianbin, MA Weikui. Design of Composite Ladle Shroud for Improving Thermal Shock Resistance [J]. China's Refractories, 2021, 30(1): 31-34. |

| [14] | GUO Hongxiang, SUN Xiaogai, JIA Quanli, LI Xueyan, LIU Xinhong. Effect of Calcium Chloride Addition on Properties of Corundum Spinel Castable [J]. China's Refractories, 2020, 29(4): 46-49. |

| [15] | DU Zhongpei, YAO Dongxu, XIA Yongfeng, ZUO Kaihui, YIN Jinwei, LIANG Hanqin, ZENG Yuping. Effect of Pore Size on Properties of Highly Porous Silica Ceramic Foams for Heat Insulation [J]. China's Refractories, 2020, 29(4): 6-9. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||