China's Refractories ›› 2021, Vol. 30 ›› Issue (3): 1-6.DOI: 10.19691/j.cnki.1004-4493.2021.03.001

Effect of Spinels on Properties of MgO-Al2O3 Refractories for RH Snorkels

- The State Key Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology, Wuhan 430081, China

-

Online:2021-09-15Published:2021-11-26 -

Contact:ZHAO Huizhong -

About author:Zhao Huizhong is a professor of Wuhan University of Science and Technology, a doctoral supervisor, and a national model of teacher ethics. He graduated from Wuhan Iron and Steel Institute in 1987 and has been engaged in refractory teaching and scientific research for nearly 35 years. He has participated in the national key scientific and technological projects from the State Key Task 75 to State Key Task 95. His main research directions include refractories for new metallurgical technology, harmless treatment and resource utilization of metallurgical solid waste, etc. He has published more than 100 papers in academic journals including more than 60 papers in SCI.

Cite this article

ZHAO Huizhong, LI Jingjie. Effect of Spinels on Properties of MgO-Al2O3 Refractories for RH Snorkels[J]. China's Refractories, 2021, 30(3): 1-6.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2021.03.001

| Starting materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | IL | True density /(g · cm-3) | Particle density /(g · cm-3) |

|---|---|---|---|---|---|---|---|---|

| Fused magnesia | 2.06 | 0.25 | 0.67 | 1.44 | 92.88 | 0.27 | 3.62 | 2.86 |

| High purity sintered magnesia | 0.78 | 0.14 | 0.59 | 1.44 | 96.02 | 0.35 | 3.60 | 3.16 |

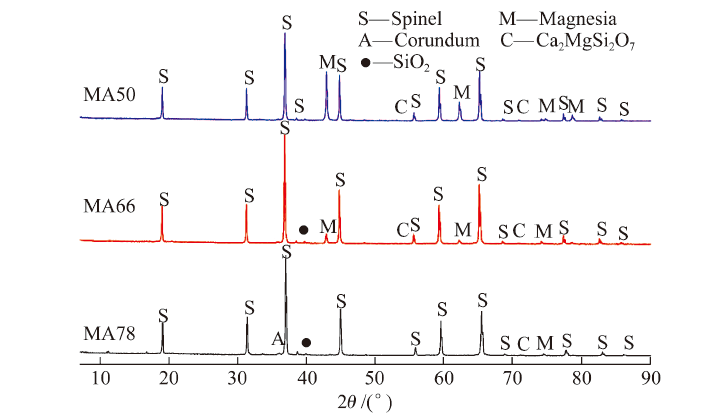

| MA50 spinel | 0.56 | 50.42 | 0.48 | 0.76 | 46.23 | 1.18 | 3.53 | 3.13 |

| MA66 spinel | 0.38 | 65.60 | 0.38 | 0.56 | 31.53 | 1.19 | 3.56 | 3.46 |

| MA78 spinel | 0.28 | 76.80 | 0.25 | 0.44 | 21.70 | 0.26 | 3.50 | 3.07 |

Table 1 Chemical and physical properties of main starting materials

| Starting materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | IL | True density /(g · cm-3) | Particle density /(g · cm-3) |

|---|---|---|---|---|---|---|---|---|

| Fused magnesia | 2.06 | 0.25 | 0.67 | 1.44 | 92.88 | 0.27 | 3.62 | 2.86 |

| High purity sintered magnesia | 0.78 | 0.14 | 0.59 | 1.44 | 96.02 | 0.35 | 3.60 | 3.16 |

| MA50 spinel | 0.56 | 50.42 | 0.48 | 0.76 | 46.23 | 1.18 | 3.53 | 3.13 |

| MA66 spinel | 0.38 | 65.60 | 0.38 | 0.56 | 31.53 | 1.19 | 3.56 | 3.46 |

| MA78 spinel | 0.28 | 76.80 | 0.25 | 0.44 | 21.70 | 0.26 | 3.50 | 3.07 |

| No. | MA50 spinel | High purity sintered magnesia | Fused magnesia fine powder | |

|---|---|---|---|---|

| 3-1 mm | 5-2 mm | 2-0 mm | <0.088 mm | |

| O | 0 | 37 | 40 | 23 |

| A | 14 | 30 | 33 | 23 |

| B | 16 | 30 | 31 | 23 |

| C | 18 | 30 | 29 | 23 |

| D | 20 | 30 | 27 | 23 |

Table 2 Formulations for investigation of spinel addition effect /mass%

| No. | MA50 spinel | High purity sintered magnesia | Fused magnesia fine powder | |

|---|---|---|---|---|

| 3-1 mm | 5-2 mm | 2-0 mm | <0.088 mm | |

| O | 0 | 37 | 40 | 23 |

| A | 14 | 30 | 33 | 23 |

| B | 16 | 30 | 31 | 23 |

| C | 18 | 30 | 29 | 23 |

| D | 20 | 30 | 27 | 23 |

| Specimens | MA50 spinel | High purity magnesia | Fused magnesia | |

|---|---|---|---|---|

| 5-2 mm | 2-0 mm | <0.088 mm | ||

| With <0.088 mm spinel | 16 | 40 | 37 | 7 |

| With 1-0 mm spinel | 16 | 31 | 33.5 | 19.5 |

| With 1-3 mm spinel | 16 | 30 | 31 | 23 |

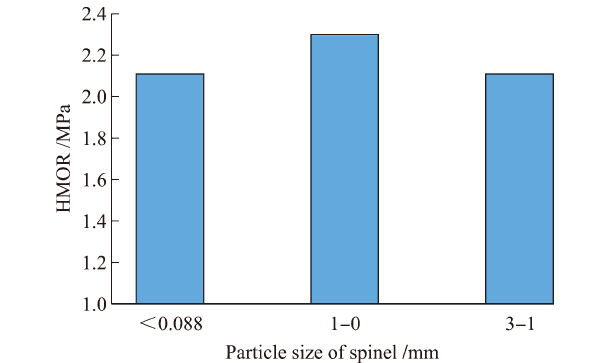

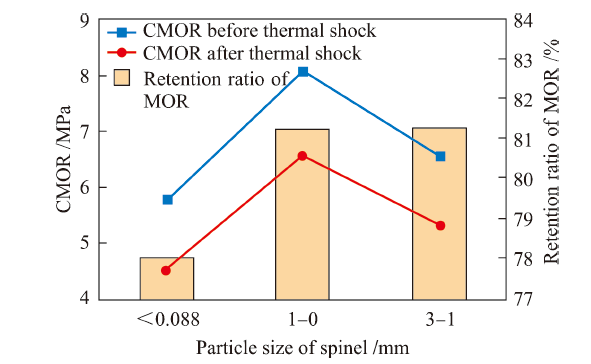

Table 3 Formulations for investigating influence of MA50 spinel size /mass%

| Specimens | MA50 spinel | High purity magnesia | Fused magnesia | |

|---|---|---|---|---|

| 5-2 mm | 2-0 mm | <0.088 mm | ||

| With <0.088 mm spinel | 16 | 40 | 37 | 7 |

| With 1-0 mm spinel | 16 | 31 | 33.5 | 19.5 |

| With 1-3 mm spinel | 16 | 30 | 31 | 23 |

| [1] | Xu Zengqi. Secondary Refining (Luwai Jinglian, in Chinese). Beijing: Metallurgical Industry Press, 2002: 147-148. |

| [2] | Li Nan, Gu Huazhi, Zhao Huizhong. Naihuo Cailiaoxue (Refractories, in Chinese). Beijing: Metallurgical Industry Press, 2010: 184. |

| [3] | Chen Zhaoyou. Refractories for RH degassers and ways of improving RH lining life. Naihuo Cailiao (Refractories, in Chinese), 2009, 43(2):81-82. |

| [4] | Zhou Feifei, Xing Fangyuan, Jiang Min, Zhang Zhao, Lu Xionggang, Li Chonghe, Jin Congjin. Study on status and prospect of chrome-free refractories in RH refining furnace. Shanghai Metals (in Chinese), 2012, 34(3):33-38. |

| [5] | A. Hayhurst, J. Laming. The structure of chrome-magnesite refractories at high temperature. Transactions of the British Ceramic Society, 1963, (12):989-1006. |

| [6] | Chen Yongqiang. Research on direct bond magnesia and alumina bricks [Dissertation, in Chinese]. Hebei: North China University of Science and Technology, 2005: 2-6. |

| [1] | HU Chen, WANG Xing, LIU Zhenglong, DING Jun, YU Chao, DENG Chengji. Effect of ZrC Modified Graphite on Structure and Properties of Low-carbon Al2O3-C Refractories [J]. China's Refractories, 2024, 33(1): 18-22. |

| [2] | CHEN Yang, DENG Chengji, DING Jun, YU Chao, LOU Xiaoming. Effect of Ferric Nitrate Loading Mode on Properties of Si3N4 Composite MgO-C Refractories Prepared by Nitridation [J]. China's Refractories, 2023, 32(3): 6-9. |

| [3] | ZHOU Lianzhuo, WANG Zhoufu, WANG Xitang, LIU Hao, MA Yan, QUAN Zhenghuang. Effect of Al Powder and Si Powder Additions on Structure and Properties of Unburned Magnesium Aluminate Spinel Refractories [J]. China's Refractories, 2023, 32(3): 14-19. |

| [4] | HAO Xian, LIU Guoqi, LI Zhixing, XU Chaojie, ZHANG Jianwei, LI Yong, LI Hongyu, LI Hongxia, FU Baoquan. Effect of Al-Si Alloy Addition on Properties of Fused Spinel Carbon Materials [J]. China's Refractories, 2022, 31(4): 45-52. |

| [5] | ZHOU Junjie, HAN Junhua. Effect of Calcium Aluminate Cement Addition on Properties of Al2O3-SiO2 Based Gunning Mixes [J]. China's Refractories, 2022, 31(3): 24-27. |

| [6] | GUO Liu, ZHAO Zongqiang, MA Junhua, CHEN Liugang. Effect of ZnO Precursor on Properties of Calcium Aluminate Cement Bonded Corundum Castables [J]. China's Refractories, 2021, 30(4): 36-39. |

| [7] | Oksana M. BORYSENKO, Galina M. SHABANOVA, Sergey M. LOGVINKOV, Lgor A. OSTAPENKO. Thermodynamic Modeling of MgO-Al2O3-TiO2 System [J]. China's Refractories, 2021, 30(3): 17-22. |

| [8] | ZHENG Juanrong, ZHANG Simi, ZHAO Zhenbo. Progress on Preparation and Characteristics of Ultra-lightweight Foam Concrete [J]. China's Refractories, 2020, 29(4): 1-5. |

| [9] | GUO Zongqi, MA Ying. Bonding Mechanisms of Basic Refractories for RH Snorkels [J]. China's Refractories, 2020, 29(4): 29-34. |

| [10] | ZHENG Han, LI Wei, DU Jiaolong, LI Hongxia, LIU Guoqi, CHEN Zihao, CHEN Yongqiang. Preparation and Properties of Si2N2O Ceramics for Microwave Sintering Furnaces [J]. China's Refractories, 2020, 29(2): 42-46. |

| [11] | GAO Zhenxin. Phase Relationship at Subsolidus Tem-perature of MgO-MgAl2O4-ZrO2 Subsystem [J]. China's Refractories, 2020, 29(1): 1-6. |

| [12] | ZHANG Yaran, MA Beiyue, YU Jingyu, SU Chang, REN Xinming, QIAN Fan, LIU Guoqi, LI Hongxia, YU Jingkun. Preparation of SiC Porous Ceramics by Crystalline Silicon Cutting Waste [J]. , 2018, 27(4): 46-50. |

| [13] | JIN Shengli, HARMUTH Harald. Investigation of Compressive Refractory Creep [J]. , 2018, 27(3): 21-27. |

| [14] | REN Xinming, MA Beiyue, SU Chang, YU Jingyu, ZHANG Yaran. Effect of Main Material Ratio on Properties of SiC-Al2O3 Porous Ceramics via Polymeric Replication Method [J]. , 2018, 27(3): 44-47. |

| [15] | CHEN Ding*, GU Huazhi, HUANG Ao, XIE Jing. Research on Alkali Resistance of Alumina-rich MgAl2O4 Spinel for Alkali Recovery Furnace [J]. , 2018, 27(2): 37-40. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||