China's Refractories ›› 2021, Vol. 30 ›› Issue (1): 7-16.DOI: 10.19691/j.cnki.1004-4493.2021.01.002

• Original article • Previous Articles Next Articles

Indispensability and Vulnerability of Magnesia-carbon Bricks for Steelmaking Process

GUO Zongqi1,*( ), ZAMBONI Stefano1, GAO Jianying2, GAN Feifang3

), ZAMBONI Stefano1, GAO Jianying2, GAN Feifang3

- 1 Trasteel International SA, Lugano CH-6900, Switzerland

2 Imerys (China) Co., Ltd., Tianjin 300457, China

3 Baoshan Iron & Steel Co., Ltd., Shanghai 201900, China

-

Online:2021-03-15Published:2021-05-01 -

Contact:GUO Zongqi -

About author:Dr. Guo Zongqi started his refractory career in 1983 after finishing his study in Xi’an University of Architecture & Technology. He then joined Luoyang Institute of Refractories Research to work on refractory researches and applications for more than 10 years. In 2001, he received his PhD degree in Ecole Polytechnique, University of Montreal, Canada. He then continues with refractory R&D activities and management in several international refractory companies. His refractory experiences include the pioneer research and production of high chromia refractories for slagging coal gasifiers and the technology development of burnt and unburnt basic bricks for steelmaking processes, cement rotary kilns and glass-making regenerators.

Cite this article

GUO Zongqi, ZAMBONI Stefano, GAO Jianying, GAN Feifang. Indispensability and Vulnerability of Magnesia-carbon Bricks for Steelmaking Process[J]. China's Refractories, 2021, 30(1): 7-16.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2021.01.002

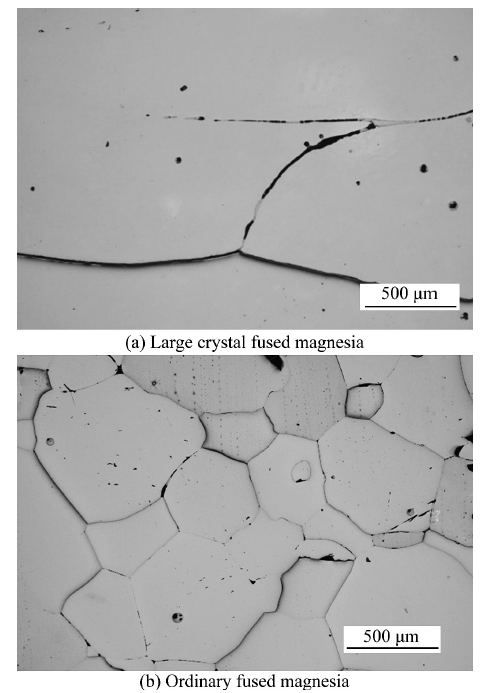

| Parameter | DOM mode | INT mode |

|---|---|---|

| Fused magnesia | Ordinary FM | Large crystal FM |

| Making process | One step | Two steps |

| Fusion input | Magnesite ore lumps | CCM briquettes |

| MgO content /mass% | > 97.50 | > 97.50 |

| Periclase crystal size /µm | 400-600 | 800-1 000 |

| MgO-C bricks /ladle | Slagline | Slagline |

| Total C content /mass% | 14 | 14 |

| Binder | Resin | Resin |

| Antioxidant | Yes | Yes |

| Ladle refining /% | 100 | 100 |

| RH degassing /% | 50-75 | 50-75 |

| Service lifetime /heat | 32-35 | 72-75 |

| Slagline in a ladle campaign | Three replacement | One replacement |

Table 1 Distinctions of magnesia-carbon bricks for slagline of ladles

| Parameter | DOM mode | INT mode |

|---|---|---|

| Fused magnesia | Ordinary FM | Large crystal FM |

| Making process | One step | Two steps |

| Fusion input | Magnesite ore lumps | CCM briquettes |

| MgO content /mass% | > 97.50 | > 97.50 |

| Periclase crystal size /µm | 400-600 | 800-1 000 |

| MgO-C bricks /ladle | Slagline | Slagline |

| Total C content /mass% | 14 | 14 |

| Binder | Resin | Resin |

| Antioxidant | Yes | Yes |

| Ladle refining /% | 100 | 100 |

| RH degassing /% | 50-75 | 50-75 |

| Service lifetime /heat | 32-35 | 72-75 |

| Slagline in a ladle campaign | Three replacement | One replacement |

| Raw material | Carbon /mass% | Volatile matter /mass% | Ash /mass% | Surface area /(m2 · g-1) |

|---|---|---|---|---|

| Flake graphite | 94.12 | 0.78 | 5.09 | 6.36 |

Table 2 Physical and chemical analyses of flake graphite

| Raw material | Carbon /mass% | Volatile matter /mass% | Ash /mass% | Surface area /(m2 · g-1) |

|---|---|---|---|---|

| Flake graphite | 94.12 | 0.78 | 5.09 | 6.36 |

| Heating temperature | Phase transformation | Description |

|---|---|---|

| At 660 °C | Al liquid | Melting starting |

| Al2O3 coating ripped | A fine layer of Al2O3 | |

| Over 660 °C | 4Al(l)+3C(s) → Al4C3(s) | Surrounding carbon |

| 2Al(s)+N2(g) → 2AlN(s) | In presence of air | |

| At 1 100 °C | Al liquid disappears | |

| Over 1 100 °C | Al4C3+3O2(g) → Al2O3+3C | In presence of air |

| 2AlN(s)+CO(g) → Al2O3(s)+N2(g)+3C(s) | ||

| Al2O3+MgO(s) → MgO·Al2O3(s) | Spinel crystals forming | |

| At 1 500 °C | Al4C3 and AlN disappear | Spinel crystals growing |

Table 3 Phase transformations of metallic Al in MgO-C brick

| Heating temperature | Phase transformation | Description |

|---|---|---|

| At 660 °C | Al liquid | Melting starting |

| Al2O3 coating ripped | A fine layer of Al2O3 | |

| Over 660 °C | 4Al(l)+3C(s) → Al4C3(s) | Surrounding carbon |

| 2Al(s)+N2(g) → 2AlN(s) | In presence of air | |

| At 1 100 °C | Al liquid disappears | |

| Over 1 100 °C | Al4C3+3O2(g) → Al2O3+3C | In presence of air |

| 2AlN(s)+CO(g) → Al2O3(s)+N2(g)+3C(s) | ||

| Al2O3+MgO(s) → MgO·Al2O3(s) | Spinel crystals forming | |

| At 1 500 °C | Al4C3 and AlN disappear | Spinel crystals growing |

| Antioxidant | Phase and VE coefficient | |

|---|---|---|

| Al | Al2O3 | MgO·Al2O3 |

| 1.30 | 1.43 | |

| Si | SiO2 | 2MgO·SiO2 |

| 2.20 | 1.95 | |

Table 4 Volume expansion (VE) of phase transformations

| Antioxidant | Phase and VE coefficient | |

|---|---|---|

| Al | Al2O3 | MgO·Al2O3 |

| 1.30 | 1.43 | |

| Si | SiO2 | 2MgO·SiO2 |

| 2.20 | 1.95 | |

| Specification | Domestic resin DH | Domestic resin RM | European resin H9905 |

|---|---|---|---|

| Viscosity at 20-25 °C /(Pa·s) | 10-16 | 1.1 (1.05-1.55) | 1.85-2.15 |

| Solid content at 135 °C /mass% | ≥ 79 | 75 (70-80) | 70-74 |

| Moisture content /mass% | ≤ 4 | 8.0 (7.0-10) | 7.0-8.0 |

| Carbon residue fired at 800 °C /mass% | ≥ 40 | 45 (≥ 39) | ~50 |

| Free phenol content GC /mass% | 9.0 ± 2.0 | 12 (10.5-13.5) | Max. 0.2 |

Table 5 Chemical and physical analyses of phenol-formaldehyde resin

| Specification | Domestic resin DH | Domestic resin RM | European resin H9905 |

|---|---|---|---|

| Viscosity at 20-25 °C /(Pa·s) | 10-16 | 1.1 (1.05-1.55) | 1.85-2.15 |

| Solid content at 135 °C /mass% | ≥ 79 | 75 (70-80) | 70-74 |

| Moisture content /mass% | ≤ 4 | 8.0 (7.0-10) | 7.0-8.0 |

| Carbon residue fired at 800 °C /mass% | ≥ 40 | 45 (≥ 39) | ~50 |

| Free phenol content GC /mass% | 9.0 ± 2.0 | 12 (10.5-13.5) | Max. 0.2 |

| Stage | DOM mode | INT mode | |

|---|---|---|---|

| Mixing | Facility | Conventional mixer | High speed intensity mixer |

| Duration | 40-50 min | < 10 min | |

| Capacity | < 1 t | 2 t | |

| Pressing | Facility | Screw press | Hydraulic press |

| Manner | Deairing, impacting | Deairing, static pressing | |

| Pressing | 8-15 strokes | 1 static pressing | |

| Charging | Weighing feeder | Volumetric feeder | |

| Green brick | Manual removal | Robotic device | |

| Output | 1 shape | 3 shapes | |

| Tempering | Tunnel kiln | Electrically heated | Fired by natural gas |

| Operation | Intermittent | Continuous | |

| Capacity | 10 000 t/a for a kiln | Min. 50 000 t/a for a kiln | |

| Duration | 12 h | 8 h | |

Table 6 Manufacturing process of MgO-C bricks

| Stage | DOM mode | INT mode | |

|---|---|---|---|

| Mixing | Facility | Conventional mixer | High speed intensity mixer |

| Duration | 40-50 min | < 10 min | |

| Capacity | < 1 t | 2 t | |

| Pressing | Facility | Screw press | Hydraulic press |

| Manner | Deairing, impacting | Deairing, static pressing | |

| Pressing | 8-15 strokes | 1 static pressing | |

| Charging | Weighing feeder | Volumetric feeder | |

| Green brick | Manual removal | Robotic device | |

| Output | 1 shape | 3 shapes | |

| Tempering | Tunnel kiln | Electrically heated | Fired by natural gas |

| Operation | Intermittent | Continuous | |

| Capacity | 10 000 t/a for a kiln | Min. 50 000 t/a for a kiln | |

| Duration | 12 h | 8 h | |

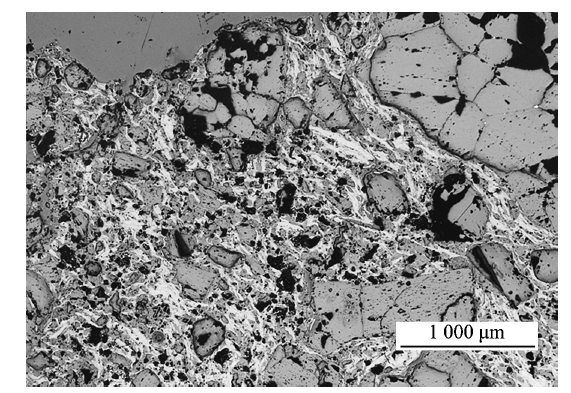

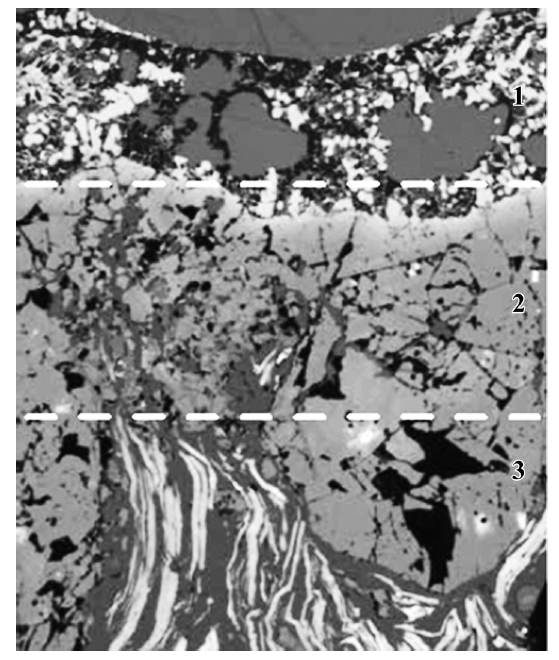

Fig. 9 Typical microstructural pattern of hot face of a used MgO-C brick (1) Slag coating, (2) Decarburization layer, (3) Partially decarburized layer

Fig. 12 Microstructure of the vertical crack, 10 mm from the hot face (1) Crack filled with slag, (2) MgO with small periclase crystals, (3) Large MgO crystal

| [1] | Kiyoshi Goto, Seiji Hanagiri, Kohji Kohno, Tsuyoshi Matsui, Tadashi Ikemoto. Progress and perspective of refractory technology. Nippon Steel Technical Report, 2013(104):21-25. |

| [2] | Zongqi Guo, Deli Bi, Shoukuan Sun. Manufacturing principles of refractory magnesia in China. Refractories Worldforum, 2021,13(1):34-41. |

| [3] | Zongqi Guo, Qiang Ding, Lei Liu. Microstructure of refractory magnesia in China. to be submitted. |

| [4] | Ruth Engel. Magnesia-carbon brick: a retrospective. The Refractories Engineer, 2013(7):19-22. |

| [5] | B. Hashemi, M. A, Faghihi-Sani, Z. A. Nemati. Effects of graphite content on the oxidation resistance of MgO-C refractory bricks. Scientia Iranica, 2005,12(3):274-279. |

| [6] | Jacques Poirier, P. Prigent, M. L. Bouchetou. The effects of fine and ultra-fine particle on the design of refractory ceramics. Refractories Worldforum, 2011,3(2):99-109. |

| [7] | K. Ichikawa, H. Nishio, O. Nomura, Y. Hoshiyama. Suppression effect of aluminum on oxidation of MgO-C bricks. Journal of the Technical Association of Refractories, Japan, 1995,15(2):21-24. |

| [8] | S. K. Sadrnezhaad, Z. A. Nemati, S. Mahshid, S. Hosseini, B. Hashemi. Effect of Al antioxidant on the rate of oxidation of carbon in MgO-C refractory. Journal of the American Ceramic Society, 2007,90(2):509-515. |

| [9] | Sherong Zhang, N. J. Marriott, W. E. Lee. Thermochemistry and microstructure of MgO-C refractories containing various antioxidants. Journal of the European Ceramic Society, 2001,21(8):1037-1047. |

| [10] | N. K. Ghosh, K. P. Jagannathan, D. N. Ghosh. Oxidation of magnesia-carbon refractories with addition of aluminum and silicon in air. Interceram, 2001,50(3):196-202. |

| [11] | A. S. Gokce, C. Gurcan, S. Ozgen, S. Aydin. The effect of antioxidants on the oxidation behaviour of magnesia-carbon refractory bricks. Ceramics International, 2008,34(2):323-330. |

| [12] | A. Yoshida. On the present status of seawater magnesia manu-facturing. Journal of the Technical Association of Refractories, Japan, 2005,25(2):89-99. |

| [13] | C. G. Aneziris, D. Borzov, G. Schmidt. Improved carbon-bonded MgO materials as smart refractories. Proceedings of Tehran International Conference on Refractories, Tehran, Iran, 2004: 56-63. |

| [14] | Gerald Buchebner, Volker Samm, Jens Rotsch. Latest Development in magnesia-carbon bricks. RHI Bulletin—The Journal of Refractory Innovations, 2011(1):23-28. |

| [15] | Winfried Boenigk, D. Schnitzler, J. Stiegert, G. Buchebner, S. Grassegger. CARBORES—a carbon speciality to improve the performance of refractories bound with phenolic resins. Proceedings of EUROCARBON 2000, 1st World Conference on Carbon, Berlin, Germany, 2000. |

| [16] | J. Poetschke. Why is MgO-C refractory material applicable in steel metallurgy? Refractories Worldforum, 2013,5(2):80-94. |

| [17] | S. K. Sadrnezhaad, S. Mahshid, B. Hashemi, Z. A. Nemati. Oxidation mechanism of C in MgO-C refractory bricks. Journal of the American Ceramic Society, 2006,89(4):1306-1316. |

| [18] | Andreas Rief, Stefan Heid, Matthias Hoeck. Effect of powder additives on MgO-C brick performance. RHI Bulletin—The Journal of Refractory Innovations, 2013(1):33-37. |

| [19] | Ashraf Hanna, Kar-Michael Zettl. Modern electric arc furnace processes and their requirements for improved lining concepts. RHI Bulletin—The Journal of Refractory Innovations, 2015(1):17-24. |

| [20] | Harald Harmuth, S. Vollmann, F. Melcher, D. Gruber, C. Majcenovic. Relevance of numerical simulation for refractory corrosion in steel industry. Proceedings of the 49th Annual Conference of Metallurgists of CIM, Vancouver, Canada, 2010: 453-463. |

| [21] | Christian Majcenovic, Johann Eder, Jens Rotsch. Microscopic examination of premature wear caused by joint opening and vertical crack formation in magnesia-carbon steel treatment ladle linings. RHI Bulletin—The Journal of Refractory Innovations, 2012(1):34-38. |

| [22] | Gerald Buchebner, Rainer Neuboeck, Johann Eder, Johann Studnicka. Thermomechanical design of magnesia-carbon bricks for steel ladles. Proceedings of 51st International Colloquium on Refractories 2008, Aachen, Germany, 2008: 70-72. |

| [1] | Carlos PAGLIOSA, Leandro ROCHA, Marcelo BORGES, Celio CAVALCANTE. Novel Brick Technology for Carbon Reduction Footprint in Steel Shop Linings [J]. China's Refractories, 2024, 33(2): 16-21. |

| [2] | HU Chen, WANG Xing, LIU Zhenglong, DING Jun, YU Chao, DENG Chengji. Effect of ZrC Modified Graphite on Structure and Properties of Low-carbon Al2O3-C Refractories [J]. China's Refractories, 2024, 33(1): 18-22. |

| [3] | LEE Yaotsung, ZHAO Lite, LEE Johnson, LIU William. Analysis of Corrosion Mechanisms of Low-cement or No-cement Al2O3-MgO Gunning Mix with Special Calcined Alumina in Rotary Slag Test [J]. China's Refractories, 2023, 32(4): 16-21. |

| [4] | XU Guotao, ZHAO Yuan, WU Jie, ZHANG Honglei, LIU Li, ZHANG Yanwen, ZHOU Wangzhi. Discussion on Abnormal Corrosion and Material Selection of Hot Iron Ladles with Steel Scrap Addition [J]. China's Refractories, 2023, 32(1): 1-5. |

| [5] | CAO Huiyan, ZHANG Xinhua, HUANG Yifei, WANG Wenwu, WU Jiguang, BU Xiangjuan, XU Haiyang. Influence of Graphite on Molten-alkali Corrosion Resistance for β-SiAlON-SiC Materials [J]. China's Refractories, 2022, 31(4): 22-27. |

| [6] | SHEN Mingke, LUO Ming, HU Chengyang, YU Yan, SONG Yanan, NI Feijiang, LI Jin. Effects of Four Kinds of Alumina Micropowder on Properties of Al2O3-C Refractories [J]. China's Refractories, 2022, 31(4): 34-38. |

| [7] | LUO Ming, FANG Binxiang, WEI Guoping, LIU Guangping, SHEN Mingke, SONG Yanan. Development and Application of Carbon-free Al2O3-MgO Dense Bricks for Steel Ladles [J]. China's Refractories, 2022, 31(2): 35-39. |

| [8] | Reinhard EHRENGRUBER, Roland BUHLMANN, Verena SCHMIDT, Magnus PERSSON. Influence of the Trends Robotics and Digitalisation on Ladle Slide Gate Development [J]. China's Refractories, 2021, 30(2): 30-34. |

| [9] | GUO Zongqi, ZAMBONI Stefano, GAN Feifang, GAO Jianying. Multifunctional Refractory-lined Vessel: Ladle Aggregate [J]. China's Refractories, 2021, 30(1): 1-6. |

| [10] | GAN Feifang, GUO Zongqi, GAO Jianying, WANG Tao, WANG Zhaohui. Innovative Lining of Unburnt Al2O3-MgO Brick for 300t Steel Ladle in Baosteel [J]. China's Refractories, 2021, 30(1): 17-22. |

| [11] | LIU Guoqi, LI Hongxia, YANG Wengang, QIAN Fan, YU Jianbin, MA Weikui. Design of Composite Ladle Shroud for Improving Thermal Shock Resistance [J]. China's Refractories, 2021, 30(1): 31-34. |

| [12] | GAN Feifang, GUO Zongqi, GAO Jianying, GAO Hua. Insulating Permanent Lining of Calcium Hexaluminate Based Castable for 300t Ladle in Baosteel [J]. China's Refractories, 2021, 30(1): 35-40. |

| [13] | GUO Zongqi, ZAMBONI Stefano, GAO Jianying, GAN Feifang. A Retrospective Review of Alumina-magnesia-carbon Refractories [J]. China's Refractories, 2021, 30(1): 41-48. |

| [14] | Jérome KIENNEMANN, Paul SOLER, Johnson LEE. Application of None Cement Alumina-magnesia Gunning Mix with Special High Reactive Alumina in Steel Ladles [J]. China's Refractories, 2020, 29(1): 20-26. |

| [15] | ZHANG Liang. Improvement of Service Life of Small Furnace Covers on 150 t Refining Ladles [J]. China's Refractories, 2020, 29(1): 40-43. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||