China's Refractories ›› 2021, Vol. 30 ›› Issue (1): 17-22.DOI: 10.19691/j.cnki.1004-4493.2021.01.003

• Original article • Previous Articles Next Articles

Innovative Lining of Unburnt Al2O3-MgO Brick for 300t Steel Ladle in Baosteel

GAN Feifang1,*( ), GUO Zongqi2, GAO Jianying3, WANG Tao1, WANG Zhaohui4

), GUO Zongqi2, GAO Jianying3, WANG Tao1, WANG Zhaohui4

- 1 Baoshan Iron & Steel Co., Ltd., Shanghai 201900, China

2 Trasteel International SA, Lugano CH-6900, Switzerland

3 Imerys (China) Co., Ltd., Tianjin 300457, China

4 Zhaohui Energy-Saving Technology Co., Ltd., Tieling 112000, China

-

Online:2021-03-15Published:2021-05-01 -

Contact:GAN Feifang -

About author:Gan Feifang, a professorship senior engineer, is the chief researcher of refractories in the Central Research Institute of Baosteel. She has been engaged in R & D and application technology research of refractories for iron and steel metallurgy for a long time, and has in-depth research on refractories for coking, iron-making and steel-making systems. She has 50 patents and published more than 30 papers. She has won one First Prize of Science and Technology Award of Metallurgical Industry, one first prize and two second prizes of major technological innovation achievements of China Baowu Group Company and one third prize of Shanghai Science and Technology Award. At present, she is in the Expert Committee of The Association China Refractory Industries, is Vice Chairman of Refractories Standardization Technical Committee of Chinese Society for Metals, and is in the 9th Editorial Board of Naihuo Cailiao (Refractories, in Chinese, Bimonthly).

Cite this article

GAN Feifang, GUO Zongqi, GAO Jianying, WANG Tao, WANG Zhaohui. Innovative Lining of Unburnt Al2O3-MgO Brick for 300t Steel Ladle in Baosteel[J]. China's Refractories, 2021, 30(1): 17-22.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2021.01.003

| Raw materials | Chemical composition /mass% (LOI-free) | Bulk density / (g·cm-3) | |||||

|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | MgO | Fe2O3 | CaO | R2O | ||

| Tabular alumina | 0.08 | 98.93 | 0.02 | 0.04 | 0.14 | 0.27 | 3.58 |

| White fused alumina | 0.23 | 99.12 | 0.02 | 3.45 | |||

| Fused MA spinel | 0.24 | 77.35 | 21.78 | 0.23 | 0.33 | 0.21 | 3.41 |

| Calcined alumina | 0.07 | 99.34 | 0.01 | 0.02 | 0.07 | 0.08 | D50 < 5 µm |

| Fused magnesia | 1.06 | 0.18 | 96.82 | 0.31 | 1.84 | 3.53 | |

| Calcium aluminate cement | 0.28 | 70.04 | 0.13 | 29.41 | 0.26 | < 15 µm | |

| G3297BX gel powder | 0.65 | 5.97 | 91.10 | 0.42 | 1.03 | 0.35 | LOI = 47.85% |

Table 1 Chemical and physical properties of raw materials used

| Raw materials | Chemical composition /mass% (LOI-free) | Bulk density / (g·cm-3) | |||||

|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | MgO | Fe2O3 | CaO | R2O | ||

| Tabular alumina | 0.08 | 98.93 | 0.02 | 0.04 | 0.14 | 0.27 | 3.58 |

| White fused alumina | 0.23 | 99.12 | 0.02 | 3.45 | |||

| Fused MA spinel | 0.24 | 77.35 | 21.78 | 0.23 | 0.33 | 0.21 | 3.41 |

| Calcined alumina | 0.07 | 99.34 | 0.01 | 0.02 | 0.07 | 0.08 | D50 < 5 µm |

| Fused magnesia | 1.06 | 0.18 | 96.82 | 0.31 | 1.84 | 3.53 | |

| Calcium aluminate cement | 0.28 | 70.04 | 0.13 | 29.41 | 0.26 | < 15 µm | |

| G3297BX gel powder | 0.65 | 5.97 | 91.10 | 0.42 | 1.03 | 0.35 | LOI = 47.85% |

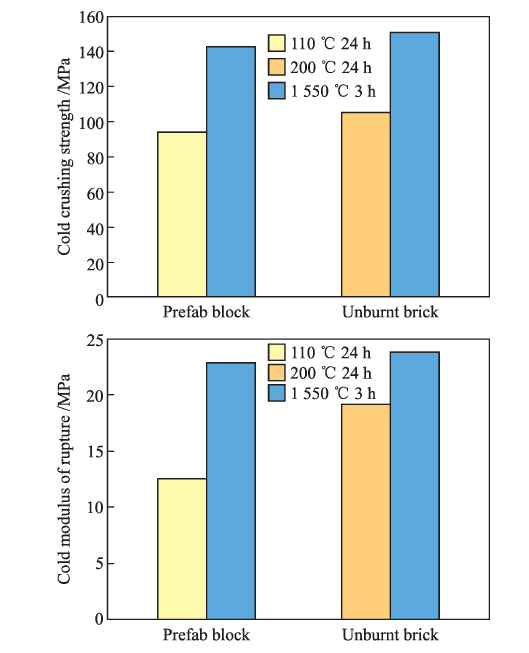

| Al2O3-MgO materials | Chemical composition /mass% | Bulk density / (g·cm-3) | Apparent porosity /% | CCS /MPa | |||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | MgO | Fe2O3 | CaO | R2O | ||||

| Unburnt brick A | 1.06 | 88.79 | 5.36 | 0.19 | 0.14 | 0.23 | 3.28 | 9 | 105 |

| Prefab block B | 0.09 | 93.15 | 3.92 | 0.07 | 0.6 | 0.10 | 3.12 | 15 | 94 |

Table 2 Chemical and physical properties of alumina-magnesia materials

| Al2O3-MgO materials | Chemical composition /mass% | Bulk density / (g·cm-3) | Apparent porosity /% | CCS /MPa | |||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | MgO | Fe2O3 | CaO | R2O | ||||

| Unburnt brick A | 1.06 | 88.79 | 5.36 | 0.19 | 0.14 | 0.23 | 3.28 | 9 | 105 |

| Prefab block B | 0.09 | 93.15 | 3.92 | 0.07 | 0.6 | 0.10 | 3.12 | 15 | 94 |

| Slag type and steel | Chemical composition /mass% | ||||

|---|---|---|---|---|---|

| SiO2 | Al2O3 | MgO | CaO | Total Fe | |

| Slag from BOF | 13.90 | 1.47 | 12.24 | 46.35 | 20.70 |

| Refining slag from ladle | 34.24 | 15.63 | 8.87 | 20.31 | 17.70 |

| Molten steel | Si | Al | C | P | Fe |

| 3.12 | 5.10 | 0.06 | 0.03 | 90.11 | |

Table 3 Chemical composition of slag and steel

| Slag type and steel | Chemical composition /mass% | ||||

|---|---|---|---|---|---|

| SiO2 | Al2O3 | MgO | CaO | Total Fe | |

| Slag from BOF | 13.90 | 1.47 | 12.24 | 46.35 | 20.70 |

| Refining slag from ladle | 34.24 | 15.63 | 8.87 | 20.31 | 17.70 |

| Molten steel | Si | Al | C | P | Fe |

| 3.12 | 5.10 | 0.06 | 0.03 | 90.11 | |

| [1] | Cui Jian, Zheng Yiyu, Zhu Lixin. Progress of production technology of clean steel in Baosteel. Engineering Sciences, 2005,3(2):25-29. |

| [2] | Zhao Huizhong, Gu Huazhi, Wang Xitang, Zhang Wenjie. Study on carbon-free unfired brick for ladles. Naihuo Cailiao (Refractories in Chinese), 2000,34(3):158-160. |

| [3] | Wang Yunchun. Development and application of the carbon-free unfired bricks for ladles. Shanxi Metallurgy (in Chinese), 2003,26(2):20-21, 40. |

| [4] | Wu Songgen, Zhong Kai, Shao Sunning. Development and application of carbon-free ladle bricks. Proceedings of 3rd International Symposium on Refractories, Beijing, China, 2008: 95-98. |

| [5] | Ye Zhongchao, Wang Shiyang. Mechanism of carbon pick-up of ultralow carbon steels in ladle. Journal of the Chinese Rare Earth Society, 1998,16(S):803-807. |

| [6] | Li Ciying, Peng Mingyao, Wang Shihua, Gan Shaojun. Analysis of carbon pick-up of ultralow carbon steel. Proceedings of Symposium on Steel Quality 2008, Benxi, China, 2008: 13-20. |

| [7] | Wen Tieguang, Sun Tao, Sun Qun, Wang Xianghui. Ultralow carbon steel carburated control. Proceedings of 7th Symposium of Iron & Steel 2009, Beijing, China, 2009: 160-163. |

| [8] | Andrew A. Russo, Jeffrey D. Smith, Ronald J, O’Malley, Von L. Richards. Mechanism for carbon transfer from magnesia-graphite ladle refractories to ultralow-carbon steel. Iron & Steel Technology, 2016,13(10):134-143. |

| [9] | Zhang Songlin, Shang Gangcheng, Peng Lijuan, Fan Mingyu, He Guozhu. Development and application of unburnt, carbon-free corundum-spinel brick for steel ladle. Modern Metallurgy (in Chinese), 2017,45(5):20-24. |

| [10] | Hu Chune, He Jiamei, Tong Xin, Qi Tongrui, Yao Huabo. Application of unburnt, carbon-free bricks for steel refining ladle and investigation of their wear mechanisms. Proceedings of Symposium on Refractories for Iron & Steel Making 2005, Wuhan, China, 2005: 86-92. |

| [11] | Feng Haixia, Liu Jun, Wei Yi. Development and application of corundum spinel non-burnt brick for refining ladle lining. Materials Engineering, 2010 (S2):406-408, 413. |

| [12] | M. Futhrer, A. Hey, W. E. Lee. Microstructural evolution in self-forming spinel/calcium aluminate-bonded castable refractories. Journal of the European Ceramic Society, 1998,18(7):813-820. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||