China's Refractories ›› 2022, Vol. 31 ›› Issue (1): 35-44.DOI: 10.19691/j.cnki.1004-4493.2022.01.006

Previous Articles Next Articles

Recent Progress on Al2O3-C Refractories with Low/ultra-low Carbon Content:A Review

ZHAO Chenrui1,*( ), YAN Mingwei2, LI Hongyu1, NIU Zhiwang1, LIANG Baoqing1, SHANG Junli1

), YAN Mingwei2, LI Hongyu1, NIU Zhiwang1, LIANG Baoqing1, SHANG Junli1

- 1 Henan Rongjin High Temperature Materials Co., Ltd., Weihui 453100, China

2 State Key Laboratory of Multiphase Complex Systems, Institute of Process Engineering,Chinese Academy of Sciences, Beijing 100190, China

-

Online:2022-03-15Published:2022-04-02 -

Contact:ZHAO Chenrui -

About author:Zhao Chenrui got his bachelor’s degree in Shaanxi University of Science and Technology in 2010, and his master’s degree in Sinosteel Luoyang Institute of Refractories Research Co., Ltd. in 2013. Now he is working in Henan Rongjin High Temperature Materials Co., Ltd., as a director of the research and development center. He is engaged in research and development of slide gate nozzle refractories and unshaped refractories for ladles, tundishes and converters. He has accumulated some experience in the design, production and application of slide gate nozzle refractories.

Cite this article

ZHAO Chenrui, YAN Mingwei, LI Hongyu, NIU Zhiwang, LIANG Baoqing, SHANG Junli. Recent Progress on Al2O3-C Refractories with Low/ultra-low Carbon Content:A Review[J]. China's Refractories, 2022, 31(1): 35-44.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2022.01.006

| Temperature | Index | GN0 | GN10 | GN21 | GN55 | GN88 |

|---|---|---|---|---|---|---|

| 800 ℃ | CMOR /MPa | 6.61±0.29 | 9.64±0.01 | 10.15±0.16 | 10.37±0.01 | 9.33±0.19 |

| E /GPa | 1.64±0.01 | 2.29±0.01 | 2.09±0.01 | 2.19±0.07 | 1.77±0.04 | |

| 1 000 ℃ | CMOR /MPa | 7.30±0.11 | 12.22±0.13 | 12.88±0.06 | 11.41±0.13 | 11.29±0.03 |

| E /GPa | 1.63±0.04 | 2.41±0.07 | 2.50±0.10 | 2.49±0.08 | 2.16±0.07 | |

| 1 200 ℃ | CMOR /MPa | 17.16±0.23 | 23.25±0.28 | 25.60±0.08 | 23.29±0.17 | 19.51±0.28 |

| E /GPa | 2.87±0.03 | 3.32±0.06 | 3.48±0.02 | 3.45±0.03 | 3.11±0.06 | |

| 1 400 ℃ | CMOR /MPa | 15.39±0.35 | 17.21±0.11 | 21.31±0.28 | 15.43±0.37 | 15.41±0.28 |

| E /GPa | 2.94±0.08 | 3.19±0.03 | 3.10±0.06 | 3.10±0.08 | 2.83±0.06 |

Table 1 CMOR and E of specimens with different amounts of GONs fired at various temperatures[16]

| Temperature | Index | GN0 | GN10 | GN21 | GN55 | GN88 |

|---|---|---|---|---|---|---|

| 800 ℃ | CMOR /MPa | 6.61±0.29 | 9.64±0.01 | 10.15±0.16 | 10.37±0.01 | 9.33±0.19 |

| E /GPa | 1.64±0.01 | 2.29±0.01 | 2.09±0.01 | 2.19±0.07 | 1.77±0.04 | |

| 1 000 ℃ | CMOR /MPa | 7.30±0.11 | 12.22±0.13 | 12.88±0.06 | 11.41±0.13 | 11.29±0.03 |

| E /GPa | 1.63±0.04 | 2.41±0.07 | 2.50±0.10 | 2.49±0.08 | 2.16±0.07 | |

| 1 200 ℃ | CMOR /MPa | 17.16±0.23 | 23.25±0.28 | 25.60±0.08 | 23.29±0.17 | 19.51±0.28 |

| E /GPa | 2.87±0.03 | 3.32±0.06 | 3.48±0.02 | 3.45±0.03 | 3.11±0.06 | |

| 1 400 ℃ | CMOR /MPa | 15.39±0.35 | 17.21±0.11 | 21.31±0.28 | 15.43±0.37 | 15.41±0.28 |

| E /GPa | 2.94±0.08 | 3.19±0.03 | 3.10±0.06 | 3.10±0.08 | 2.83±0.06 |

| Temperature | Index | N0 | N0.05 | N0.1 | N0.3 | N0.5 | N1 |

|---|---|---|---|---|---|---|---|

| 800 ℃ | CMOR /MPa | 4.27 | 5.76 | 4.63 | 4.50 | 4.44 | 3.07 |

| E /MPa | 1000.16 | 1329.41 | 1109.59 | 1045.87 | 1042.8 | 772.96 | |

| 1 000 ℃ | CMOR /MPa | 9.09 | 12.08 | 10.66 | 10.08 | 9.94 | 7.77 |

| E /MPa | 1702.95 | 2388.14 | 2026.56 | 1958.47 | 1762.02 | 1605.1 | |

| 1 200 ℃ | CMOR /MPa | 14.11 | 23.76 | 22.51 | 21.91 | 18.49 | 16.88 |

| E /MPa | 2540.91 | 3733.36 | 3596.59 | 3316.75 | 3142.68 | 2992.48 | |

| 1 400 ℃ | CMOR /MPa | 9.41 | 14.98 | 10.57 | 9.55 | 9.02 | 8.9 |

| E /MPa | 2257.97 | 2606.00 | 2488.89 | 2160.18 | 2109.00 | 2038.4 |

Table 2 CMOR and E of specimens with different amounts of MWCNTs fired at various temperatures[19]

| Temperature | Index | N0 | N0.05 | N0.1 | N0.3 | N0.5 | N1 |

|---|---|---|---|---|---|---|---|

| 800 ℃ | CMOR /MPa | 4.27 | 5.76 | 4.63 | 4.50 | 4.44 | 3.07 |

| E /MPa | 1000.16 | 1329.41 | 1109.59 | 1045.87 | 1042.8 | 772.96 | |

| 1 000 ℃ | CMOR /MPa | 9.09 | 12.08 | 10.66 | 10.08 | 9.94 | 7.77 |

| E /MPa | 1702.95 | 2388.14 | 2026.56 | 1958.47 | 1762.02 | 1605.1 | |

| 1 200 ℃ | CMOR /MPa | 14.11 | 23.76 | 22.51 | 21.91 | 18.49 | 16.88 |

| E /MPa | 2540.91 | 3733.36 | 3596.59 | 3316.75 | 3142.68 | 2992.48 | |

| 1 400 ℃ | CMOR /MPa | 9.41 | 14.98 | 10.57 | 9.55 | 9.02 | 8.9 |

| E /MPa | 2257.97 | 2606.00 | 2488.89 | 2160.18 | 2109.00 | 2038.4 |

| [1] |

Emad Mohamed M. EWAIS. Carbon based refractories. Journal of the Ceramic Society of Japan, 2004, 112(10):517-532.

DOI URL |

| [2] |

Ma Beiyue, Yu Jingkun. Synthesis of ZrO2-SiC composite powder and effect of its addition on properties of Al2O3-C refractories. Transactions of Nonferrous Metals Society of China, 2007, 17(5):996-1000.

DOI URL |

| [3] |

Ali Baghaei, Amirabbas Nourbakhsh, Reza Ebrahimi-Kahrizsang, Vânia Regina Salvini. Correlation of microstructure and mechanical properties of Al2O3-C bodies containing nano-Al2O3 and nano-TiO2 additives. International Journal of Applied Ceramic Technology, 2020, 17:1505-1513.

DOI URL |

| [4] |

A. Mertke, C. G. Aneziris. The influence of nanoparticles and functional metallic additions on the thermal shock resistance of carbon bonded alumina refractories. Ceramics International, 2015, 41(1):1541-1552.

DOI URL |

| [5] |

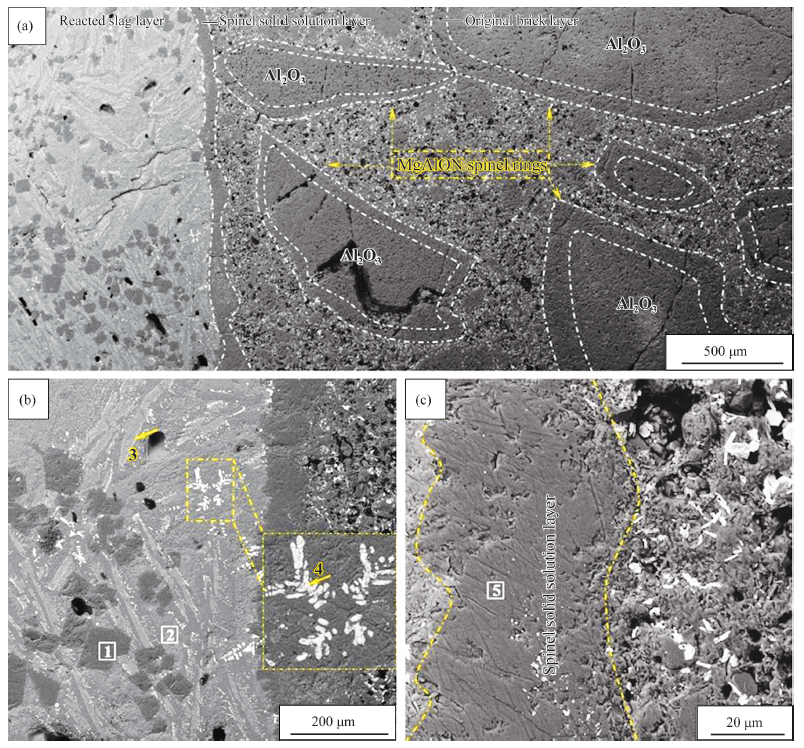

V. Roungos, C. G. Aneziris. Improved thermal shock performance of Al2O3-C refractories due to nanoscaled additives. Ceramics International, 2012, 38(2):919-927.

DOI URL |

| [6] |

Xing Wang, Yang Chen, Chao Yu, Jun Ding, Ding Guo, Chengji Deng, Hongxi Zhu. Preparation and application of ZrC-coated flake graphite for Al2O3-C refractories. Journal of Alloys and Compounds, 2019, 788(5):739-747.

DOI URL |

| [7] |

Rita Khanna, Veena Sahajwalla, Brenton Rodgers, Fiona McCarthy. Dissolution of carbon from alumina-carbon mixtures into liquid iron: Influence of carbonaceous materials. Metallurgical and Materials Transactions B, 2006, 37:623-632.

DOI URL |

| [8] |

Venkatesh Pilli, Ritwik Sarkar. Study on the nanocarbon containing Al2O3-C continuous casting refractories with reduced fixed carbon content. Journal of Alloys and Compound, 2019, 781(15):149-158.

DOI URL |

| [9] | Zhang S W. Next generation carbon-containing refractory composites. Advances in Science and Technology, 2016, 45(1):2246-2253. |

| [10] |

Lihua Lyu, Guoqing Xiao, Donghai Ding. Improved thermal shock resistance of low-carbon Al2O3-C refractories fabricated with C/MgAl2O4 composite powders. Ceramics International, 2021, 47(14):20169-20177.

DOI URL |

| [11] | V. Stein, C. G. Aneziris. Low-carbon carbon-bonded alumina refractories for functional components in steel technology. Journal of Ceramic Science and Technology, 2014, 5(2):115-124. |

| [12] |

Dingqiao Guo, Xiangcheng Li, Pingan Chen, Boquan Zhu, Binxiang Fang. Microstructure evolution and its effect on thermo-mechanical properties of low-carbon Al2O3-C refractories. Ceramics International, 2016, 42(16):19071-19078.

DOI URL |

| [13] |

Haibing Fan, Yawei Li, Shaobai Sang. Microstructures and mechanical properties of Al2O3-C refractories with silicon additive using different carbon sources. Materials Science and Engineering: A, 2011, 528(7-8):3177-3185.

DOI URL |

| [14] |

Venkatesh Pilli, Ritwik Sarkar. Nanocarbon containing Al2O3-C continuous casting refractories: Effect of graphite content. Journal of Alloys and Compound, 2018, 735:1730-1736.

DOI URL |

| [15] |

Venkatesh Pilli, Ritwik Sarkar. Low carbon containing Al2O3-C refractories with nanocarbon as the sole carbon source. Ceramics International, 2020, 46(8):12812-12821.

DOI URL |

| [16] |

Qinghu Wang, Yawei Li, Ming Luo, Shaobai Sang, Tianbin Zhu, Lei Zhao. Strengthening mechanism of graphene oxide nanosheets for Al2O3-C refractories. Ceramics International, 2014, 40(1):163-172.

DOI URL |

| [17] | Sun Xudong, Yuan Lin, Chen Songlin, Wang Juntao, Yan Xi, Liu Shifan, Song Yunjie. Effect of graphene nanosheets on properties of low carbon Al2O3-ZrO2-C slide gate. Journal of the Chinese Ceramic Society (in Chinese), 2020, 48(12):1988-1996. |

| [18] |

Donghai Ding, Lihua Lyu, Guoqing Xiao, Yun Ren, Shoulei Yang, Pan Yang, Xing Hou. One-step synthesis of in situ multilayer graphene containing MgAl2O4 spinel composite powders. Ceramics International, 2019, 45(5):6209-6215.

DOI |

| [19] |

Ming Luo, Yawei Li, Shengli Jin, Shaobai Sang, Lei Zhao, Yuanbing Li. Microstructures and mechanical properties of Al2O3-C refractories with addition of multi-walled carbon nanotubes. Materials Science and Engineering: A, 2012, 548:134-141.

DOI URL |

| [20] |

Ming Luo, Yawei Li, Shengli Jin, Shaobai Sang, Lei Zhao, Qinghu Wang, Yuanbing Li. Microstructure and mechanical properties of multi-walled carbon nanotubes containing Al2O3-C refractories with addition of polycarbosilane. Ceramics International, 2013, 39(5):4831-4838.

DOI URL |

| [21] |

Ning Liao, Yawei Li, Shengli Jin, Shaobai Sang, Gengfu Liu. Reduced brittleness of multi-walled carbon nanotubes (MWCNTs) containing Al2O3-C refractories with boron carbide. Materials Science and Engineering: A, 2017, 698:80-87.

DOI URL |

| [22] |

Ning Liao, Yawei Li, Qinghu Wang, Tianbin Zhu, Shengli Jin, Shaobai Sang, Dechang Jia. Synergic effects of nano carbon sources on thermal shock resistance of Al2O3-C refractories. Ceramics International, 2017, 43(16):14380-14388.

DOI URL |

| [23] |

Qinghu Wang, Yawei Li, Shaobai Sang, Shengli Jin. Effect of the reactivity and porous structure of expanded graphite (EG) on microstructure and properties of Al2O3-C refractories. Journal of Alloys and Compounds, 2015, 645:388-397.

DOI URL |

| [24] |

Shantanu KBehera, Bhagirath Mishra. Strengthening of Al2O3-C slide gate plate refractories with expanded graphite. Ceramics International, 2015, 41(3):4254-4259.

DOI URL |

| [25] |

Qinghu Wang, Yawei Li, Ning Liao, Xiaofeng Xu, Shaobai Sang, Yibiao Xu, Guanghui Wang, Mithun Nath. Synthesis of boron and nitrogen-doped expanded graphite as efficient reinforcement for Al2O3-C refractories. Ceramics International, 2017, 43(18):16710-16721.

DOI URL |

| [26] |

Qinghu Wang, Yawei Li, Shengli Jin, Shaobai Sang, Yibiao Xu, Xiaofeng Xu, Guanghui Wang. Enhanced mechanical properties of Al2O3-C refractories with silicon hybridized expanded graphite. Materials Science and Engineering: A, 2018, 709:160-171.

DOI URL |

| [27] |

Heng Wang, Yawei Li, Tianbin Zhu, Shaobai Sang, Qinghu Wang. Microstructures and mechanical properties of Al2O3-C refractories with addition of microcrystalline graphite. Ceramics International, 2014, 40(7):11139-11148.

DOI URL |

| [28] |

Heng Wang, Yawei Li, Shaobai Sang, Shengli Jin, Yibiao Xu, Kaibao Yang, Shuzhong Yu. Microstructures and mechanical properties of Al2O3-C refractories using nickel-loaded ultrafine microcrystalline graphite and silicon additives. Ceramics International, 2014, 40(10):15783-15793.

DOI URL |

| [29] |

Heng Wang, Yawei Li, Tianbin Zhu, Zhengyi Fu. Strengthening of Al2O3-C slide gate plate refractories with microcrystalline graphite. Ceramics International, 2017, 43(13):9912-9918.

DOI URL |

| [30] | Shunsuke Irie, James Rappolt. Phenolic resin for refractories. Phenolic Resins A Century of Progress, 2010: 503-515. |

| [31] |

Fucheng Wang, Lei Zhao, Wei Fang, Xuan He, Feng Liang, Hui Chen, Huan Chen, Xing Du. Preparation of organic/inorganic composite phenolic resin and application in Al2O3-C refractories. International Journal of Applied Ceramic Technology, 2016, 13(1):133-139.

DOI URL |

| [32] |

Jiu Zhang, Guohui Mei, Zhi Xie, Shumao Zhao. Firing mechanism of oxide-carbon refractories with phenolic resin binder. Ceramics International, 2018, 44(5):5594-5600.

DOI URL |

| [33] |

Haiyun Jiang, Jigang Wang, Shenqing Wu, Baosheng Wang, Zhangzhong Wang. Pyrolysis kinetics of phenol-formaldehyde resin by non-isothermal thermogravimetry. Carbon, 2010, 48(2):352-358.

DOI URL |

| [34] |

Atul V. Maldhure, Atul V. Wankhade. In-situ development of carbon nanotubes network and graphitic carbon by catalytic modification of phenolic resin binder in Al2O3-MgO-C refractories. Journal of Asian Ceramic Societies, 2017, 5(3):247-254.

DOI URL |

| [35] |

Tzeng S S, Chr Y G. Evolution of microstructure and properties of phenolic resin-based carbon/carbon composites during pyrolysis. Materials Chemistry and Physics, 2002, 73(2-3):162-169.

DOI URL |

| [36] |

Ming Luo, Yawei Li, Shaobai Sang, Lei Zhao, Shengli Jin, Yuanbing Li. In situ formation of carbon nanotubes and ceramic whiskers in Al2O3-C refractories with addition of Ni-catalyzed phenolic resin. Materials Science and Engineering: A, 2012, 558:533-542.

DOI URL |

| [37] |

Yongqiang Chen, Guoqi Liu, Xiaojing Hou, Fengling Yang, Bingbing Fan, Rui Zhang, Hongxia Li. Influence of bonding carbon on low carbon Al2O3-C refractory composites. Ceramics International, 2017, 43(17):14599-14607.

DOI URL |

| [38] |

Sina Darban, Mahdi Ghassemi Kakroudi, Mohammad Bavand Vandchali, Nasser Pourmohammadie Vafa, Firouz Rezaei, Vahid Charkhesht. Characterization of Ni-doped pyrolyzed phenolic resin and its addition to the Al2O3-C refractories. Ceramics International, 2020, 46(13):20954-20962.

DOI URL |

| [39] |

Ning Liao, Yawei Li, Shengli Jin, Shaobai Sang, Harald Harmuth. Enhanced mechanical performance of Al2O3-C refractories with nano carbon black and in-situ formed multi-walled carbon nanotubes (MWCNTs). Journal of the European Ceramic Society, 2016, 36(3):867-874.

DOI URL |

| [40] |

Boquan Zhu, Yuenan Zhu, Xiangcheng Li, Fei Zhao. Effect of ceramic bonding phases on the thermo-mechanical properties of Al2O3-C refractories. Ceramics International, 2013, 39(6):6069-6076.

DOI URL |

| [41] |

Haibing Fan, Yawei Li, Yupeng Huang, Shaobai Sang, Yuanbing Li, Lei Zhao. Microstructures and mechanical properties of Al2O3-ZrO2-C refractories using silicon, microsilica or their combination as additive. Materials Science and Engineering: A, 2012, 545:148-154.

DOI URL |

| [42] |

Xing Deng, Xiangcheng Li, Boquan Zhu, Pingan Chen. In-situ synthesis mechanism of plate-shaped β-SiAlON and its effect on Al2O3-C refractory properties. Ceramics International, 2015, 41(10):14376-14382.

DOI URL |

| [43] |

Zhenglong Liu, Chengji Deng, Chao Yu, Xing Wang, Jun Ding, Hongxi Zhu. Preparation of in situ grown silicon carbide whiskers onto graphite for application in Al2O3-C refractories. Ceramics International, 2018, 44(12):13944-13950.

DOI URL |

| [44] |

Jie Zhang, Xiangcheng Li, Wei Gong, Pingan Chen, Boquan Zhu. First-principles simulation of the growth of in situ synthesised β-Sialon and its effects on the thermo-mechanical properties of Al2O3-C refractory composites. Journal of the European Ceramic Society, 2019, 39(8):2739-2747.

DOI |

| [45] |

Jie Zhang, Xiangcheng Li, Wei Gong, Pingan Chen, Boquan Zhu. Simulation and experimental investigation of preferred β-Sialon growth and its effects on thermo-mechanical properties of Al2O3-C refractories. Ceramics International, 2019, 45(14):17298-17304.

DOI URL |

| [46] |

Chaofan Yin, Xiangcheng Li, Pingan Chen, Boquan Zhu. Thermo-mechanical properties of Al2O3-C refractories with in situ synthesized non-oxide bonding phases. Ceramics International, 2019, 45(6):7427-7436.

DOI |

| [47] |

C. Atzenhofer, S. Gschiel, H. Harmuth. Phase formation in Al2O3-C refractories with Al addition. Journal of the European Ceramic Society, 2017, 37(4):1805-1810.

DOI URL |

| [48] |

Yawei Li, Jiangbo Shan, Ning Liao, Shaobai Sang, Dechang Jia. Enhanced thermal shock resistance of low-carbon Al2O3-C refractories with direct CVD synthesis of nano carbon decorated oxides. Journal of the European Ceramic Society, 2018, 38(9):3379-3386.

DOI URL |

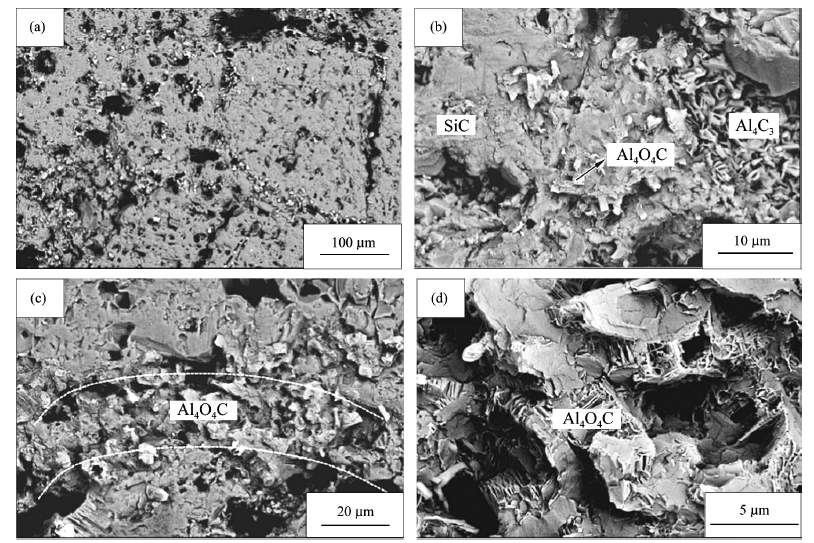

| [49] | Chao Yu, Bo Dong, Chengji Deng, Jun Ding, Hongxi Zhu, Jinghui Di. In-situ formation of plate-like Al4O4C and MWCNTs in Al2O3-C refractories with Al4SiC4 additives. Materials Chemistry and Physics, 2021, 263:1-10. |

| [50] |

Chao Yu, Chengji Deng, Hongxi Zhu, Zhengliang Xue, Jun Ding, Shimin Zhou. Synthesis of hexagonal plate-like Al4Si2C5 and the effect of Al4Si2C5 addition to Al2O3-C refractory. Advanced Powder Technology, 2017, 28(1):177-184.

DOI URL |

| [51] |

Junfeng Chen, Liugang Chen, Yaowu Wei, Nan Li, Shaowei Zhang. Corrosion and penetration behaviors of slag/steel on the corroded interfaces of Al2O3-C refractories: Role of Ti3AlC2. Corrosion Science, 2018, 143:166-176.

DOI URL |

| [52] |

Junfeng Chen, Nan Li, Wen Yan, Yaowu Wei, Bingqiang Han. Influence of Ti3AlC2 on microstructure and thermal mechanical properties of Al2O3-Ti3AlC2-C refractories. Ceramics International, 2016, 42(12):14126-14134.

DOI URL |

| [53] |

Gengfu Liu, Ning Liao, Mithun Nath, Yawei Li, Shaobai Sang. Optimized mechanical properties and oxidation resistance of low carbon Al2O3-C refractories through Ti3AlC2 addition. Journal of the European Ceramic Society, 2021, 41(4):2948-2957.

DOI URL |

| [54] | Sun Jialin, Hong Yanruo. Progression of non-oxide composite refractories in China(I)—Development and application of new products. Naihuo Cailiao (in Chinese), 2006, 40(s):77-83. |

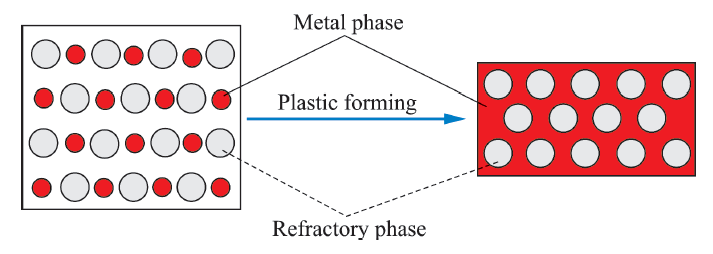

| [55] | Li Yong, Zhang Junjie, Li Jinbao, Xue Wendong, Chen Junhong, Sun Jialin. Preparation of Al-Al2O3 composite sliding gate by transient plastic phase process. Journal of the Chinese Ceramic Society (in Chinese), 2013, 41(3):416-421. |

| [56] |

Peng Jiang, Jialin Sun, Wendong Xue, Junhong Chen, R, Vasant Kumar, Yong Li. New synthetic route to Al4O4C reinforced Al-Al2O3 composite materials. Solid State Science, 2015, 46:33-36.

DOI URL |

| [57] |

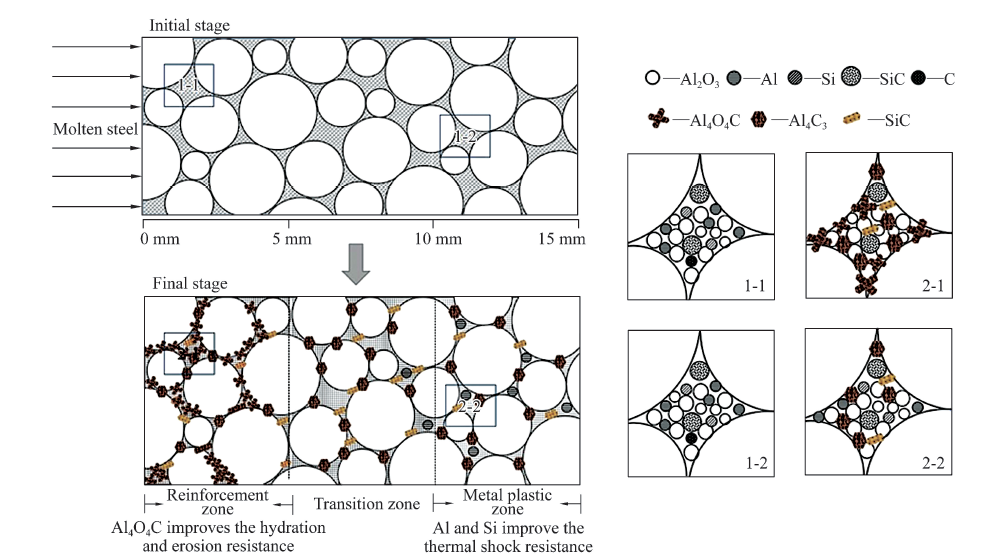

Mingwei Yan, Yong Li, Hongyu Li, Jialin Sun. Theoretical analysis and synthesis of Al4O4C and Al2CO phase in the resin bonded Al-Al2O3 refractory in N2-flowing. Ceramics International, 2018, 44(2):1493-1499.

DOI URL |

| [58] |

Xiaofang Wu, Yong Li, Chenhong Ma, Peng Jiang, Jialin Sun. Study on phase evolution of the resin bonded Al-Al2O3 composites in N2-flowing at high temperature. Journal of Alloys and Compounds, 2019, 784:1145-1152.

DOI |

| [59] | Li Chuanjing, Li Yong, Qin Haixia, Sun Jialin, Chen Junhong, Xue Wendong. Structure and properties of Al-Si3N4-Al2O3 composite prepared under nitrogen atmosphere. Journal of the Chinese Ceramic Society (in Chinese), 2014, 42(12):1579-1584. |

| [60] |

Xiaofang Wu, Yong Li, Peng Jiang, Chenhong Ma, Jialin Sun. Effect of Si3N4 mesophase on the formation of Al2OC-AlNss in resin-bonded Al-Al2O3 composites. Ceramics International, 2021, 47(18):25491-25496.

DOI URL |

| [61] |

Ma Chenghong, Li Yong, Zhang Lixin, Xue Wendong, Sun Jialin. Formation of (Al2OC)1-x(AlN)x solid solution starting from Al-Si-Al2O3 powder matrix at 1 300 °C in flowing nitrogen. Journal of the American Ceramic Society, 2019, 102(10):6349-6356.

DOI URL |

| [62] |

Shanghao Tong, Yong Li, Jizeng Zhao, Mingwei Yan, Jialin Sun, Peng Jiang, R, Vasant Kumar. Effect of Al addtion on creep resistance of MgO-Al2O3 sliding plate at 1 400 °C. Ceramics International, 2017, 43(15):11610-11615.

DOI URL |

| [63] | Yan Mingwei. Investigation on performance of resin bonded Al-Al2O3-MgO-ZrO2 composites at high temperatures in nitrogen [Dissertation, (in Chinese)]. Beijing: University of Science and Technology Beijing, 2020: 58-70. |

| [64] |

Yang Sun, Yong Li, Lixin Zhang, Shiming Li, Mingwei Yan, Jialin Sun. Novelty phase synthesis mechanism and morphology in resin bonded Al-Al2O3-TiO2 composites at high temperatures in flowing N2. International Journal of Minerals, Metallurgy and Materials, 2019, 26(9):1177-1185.

DOI URL |

| [65] | Yang Sun, Yong Li, Lixin Zhang, Yinan Shen, Mingwei Yan, Chenhong Ma, Jialin Sun. Formation mechanism and controllable preparation of Ti(C,N) in Al-TiO2-Al2O3 composite at 1 673 K in flowing N2. Materials Chemistry and Physics, 2020, 239:1-8. |

| [66] | Sun Yang. Investigation on performance of resin-bonded Al-Al2O3 refractories with TiO2 and MgO addition [Dissertation, (in Chinese)]. Beijing: University of Science and Technology Beijing, 2021, 56-61. |

| [67] |

Guotian Ye, Junli Shang, Dongrui Zhang, Min Liang, Yaosheng Chen. Synthesis and oxidation behavior of MgAlON prepared from different starting materials. Journal of the American Ceramic Society, 2010, 93(2):322-325.

DOI URL |

| [68] |

Takeshi Tsuchida, Yasunori Azuma. Oxidation behavior of (Al2OC)1-x(AlN)x and AlN in TG-DTA. Thermochimic Acta, 1999, 334(1-2):67-71.

DOI URL |

| [69] |

Zhang Shaowei, Yamaguchi A. Hydration resistances and reactions with CO of Al4O4C and Al2OC formed in carbon-containing refractories with Al. Journal of the Ceramic Society of Japan, 1996, 104(1209):393-398.

DOI URL |

| [70] |

S. Pichlbauer, H. Harmuth, Z. Lenčéš, P. Šajgalík. Preliminary investigations of the production of MgAlON bonded refractories. Journal of the European Ceramic Society, 2012, 32(9):2013-2018.

DOI URL |

| [71] |

Chenhong Ma, Yong Li, Mingwei Yan, Yang Sun, Jialin Sun. Investi-gation on a postmortem resin-bonded Al-Si-Al2O3 sliding gate with functional gradient feature. Ceramics International, 2018, 44(6):6384-6389.

DOI URL |

| [72] |

Mingwei Yan, Yong Li, Hongyu Li, Yang Sun, Haixia Qin, Qingyao Zheng. Preparation and ladle slag resistance mechanism of MgAlON bonded Al2O3-MgAlON-Zr2Al3C4-(Al2OC)1-x(AlN)x refractories. Ceramics International, 2019, 45(1):346-353.

DOI |

| [73] | Yang Sun, Yong Li, Lixin Zhang, Yuan Gao, Jialin Sun. Oxidation mechanism of Al-TiO2-MgO-Al2O3 composites after the treatment at 1 500 °C in N2-blowing. Materials Chemistry and Physics, 2020, 248:1-7. |

| [1] | WANG Li, LIU Shijie, WEI Haoyu, MA Juanjuan, DONG Binbin, GENG Shangrui, YAN Miaoxin, QIN Feng, GUO Yusen. Aluminum and Activated Alumina Powder Additions on Microwave Synthesis of Al4SiC4 [J]. China's Refractories, 2024, 33(1): 44-48. |

| [2] | ZHOU Lianzhuo, WANG Zhoufu, WANG Xitang, LIU Hao, MA Yan, QUAN Zhenghuang. Effect of Al Powder and Si Powder Additions on Structure and Properties of Unburned Magnesium Aluminate Spinel Refractories [J]. China's Refractories, 2023, 32(3): 14-19. |

| [3] | HAO Xian, LIU Guoqi, LI Zhixing, XU Chaojie, ZHANG Jianwei, LI Yong, LI Hongyu, LI Hongxia, FU Baoquan. Effect of Al-Si Alloy Addition on Properties of Fused Spinel Carbon Materials [J]. China's Refractories, 2022, 31(4): 45-52. |

| [4] | HAN Xiaoyuan, SHI Kai, XIA Yi, WANG Peixun, LIU Yang, SHANG Jianzhao. Effects of Three Silicon-based Raw Materials on Properties and Microstructure of MgO-Al-C Materials [J]. China's Refractories, 2021, 30(4): 30-35. |

| [5] | SU Chang, MA Beiyue, REN Xinming, LIU Guoqiang, ZHU Qiang. Effect of Starch Addition on Properties of Corundum-mullite Porous Ceramics [J]. China's Refractories, 2020, 29(4): 19-22. |

| [6] | GUO Zongqi, MA Ying, NEUBOECK Rainer, KOECK Andreas. Thermal Evolution of Al-containing Magnesia Refractories for RH Snorkels [J]. , 2019, 28(1): 1-6. |

| [7] | LIU Jiangbo, WANG Zhoufu, LIU Hao, WANG Xitang, MA Yan. Effect of Y2O3 Addition on Sintering Properties and Microstructure of Spinel Materials [J]. , 2018, 27(1): 39-43. |

| [8] | HUANG Jiayuan*,YANG Min,WANG Ziqiang, WANG Dongdong, ZHOU Huijun, YU Lingyan, JIANG Xin. Key Refractories Application in Hazelett Strip-casting Process [J]. , 2016, 25(4): 29-32. |

| [9] | Fernando VERNILLI,Adriel Claro de FARIA,Mateus Gomes VERNILLI, Augusto Celso AMOEDO, Eduardo Jose Togni CARDILLO, Taner Augusto MAIA, Matheus MARTINI. Non-wetting Additive as a Solution to Minimize the Corrosion of Refractory Castables Against Molten Aluminum [J]. , 2016, 25(1): 20-25. |

| [10] | YANG Weiran, QIN Haixia. Recent Development of Metal and Non-oxide Refractory Raw Materials in China [J]. , 2015, 24(3): 49-54. |

| [11] | WANG Xian, ZHU Boquan, LI Xiangcheng, MA Zheng, WEI Ying. Effect of Spherical Ni Powder on Microstructure of Secondary Carbon in MgO-C Refractories Matrix [J]. , 2015, 24(2): 42-45. |

| [12] | LIANG Feng, XUE Zhengliang, ZHAO Lei, FANG Wei, YE Linfeng, LEI Zhongxing. Replacement of Flake Graphite in Alumina-carbon Refractories by Hexagonal Boron Nitride [J]. , 2014, 23(4): 36-40. |

| [13] | LIU Xinhong, YE Fangbao, ZHONG Xiangchong. Evolution of Phase Composition and Microstructure of Al2O3-Si-Al Composite at High Temperatures in Reducing Atmosphere [J]. , 2014, 23(4): 32-35. |

| [14] | LIU Haitao, MIN Xin, JI Haipeng, XU Youguo, FANG Minghao, LIU Yan'gai, HUANG Zhaohui. Phase Composition Analysis of TiN-Al2O3 Synthesized from Aluminum-containing Dross and Rutile by Aluminothermic Reduction-nitridation Method [J]. , 2014, 23(3): 40-43. |

| [15] | ZHAO Fei, ZHU Boquan, LI Xiangcheng, ZHU Yuenan. Influences of Al and Si Powders on Microstructure and Hot Mechanical Properties of Al2O3-C Slide Plates [J]. , 2014, 23(3): 31-34. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||