China's Refractories ›› 2021, Vol. 30 ›› Issue (1): 23-30.DOI: 10.19691/j.cnki.1004-4493.2021.01.004

• Original article • Previous Articles Next Articles

Role of Calcium Magnesium Aluminate in Carbon-containing Bricks for Steel Ladle

GAO Jianying1,*( ), WOHRMEYER Christoph2, DETEUF Cyrille2

), WOHRMEYER Christoph2, DETEUF Cyrille2

- 1 Imerys Aluminates (China) Co., Ltd., Tianjin 300457, China

2 Imerys Aluminates, Puteaux 92800, France

-

Online:2021-03-15Published:2021-05-01 -

Contact:GAO Jianying -

About author:Dr. Gao Jianying was born in 1977 in Inner Mongolia. He studied in Xi’an University of Architecture and Technology and obtained his bachelor’s degree in 1999 and master’s degree in 2002. He received his PhD from Shanghai Institute of Ceramics, Chinese Academy of Science, in 2005. He joined RHI R&D team in 2006 and gained plenty of experiences on microstructural research of basic shaped refractories. Since 2011, he has been working in Imerys Aluminates (ex-Kerneos) and taking critical positions of R&D Manager, Senior Technical Manager and Refractory Technical Director. His responsibilities cover technical support for refractory businesses, advanced ceramics and investment casting. He is engaged in not only application development but also knowhow generation of various refractory raw materials. In addition, he works as a visiting professor and a supervisor for master students in the school of Materials Engineering, Xi’an University of Architecture and Technology.

Cite this article

GAO Jianying, WOHRMEYER Christoph, DETEUF Cyrille. Role of Calcium Magnesium Aluminate in Carbon-containing Bricks for Steel Ladle[J]. China's Refractories, 2021, 30(1): 23-30.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2021.01.004

| Item | Specification | |

|---|---|---|

| Chemical composition | Al2O3 | 69%-72% |

| MgO | 19%-22% | |

| CaO | 7.5%-10.5% | |

| Phase constituent | CaO·Al2O3 | 18%-22% |

| CaO·2Al2O3 | 8%-12% | |

| MgAl2O4 | 68%-72% | |

| Physical property | Bulk density | 2.2-2.4 g/cm3 |

| Apparent porosity | 24%-32% | |

| Refractoriness | 1 755 ℃ | |

Table 1 Chemical composition, phase constituent and physical properties of MagArmour

| Item | Specification | |

|---|---|---|

| Chemical composition | Al2O3 | 69%-72% |

| MgO | 19%-22% | |

| CaO | 7.5%-10.5% | |

| Phase constituent | CaO·Al2O3 | 18%-22% |

| CaO·2Al2O3 | 8%-12% | |

| MgAl2O4 | 68%-72% | |

| Physical property | Bulk density | 2.2-2.4 g/cm3 |

| Apparent porosity | 24%-32% | |

| Refractoriness | 1 755 ℃ | |

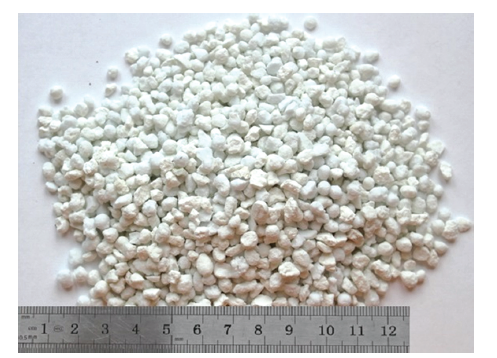

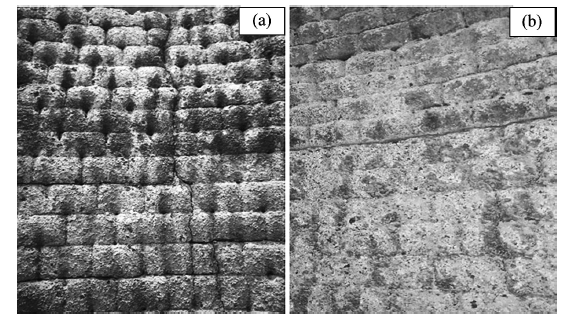

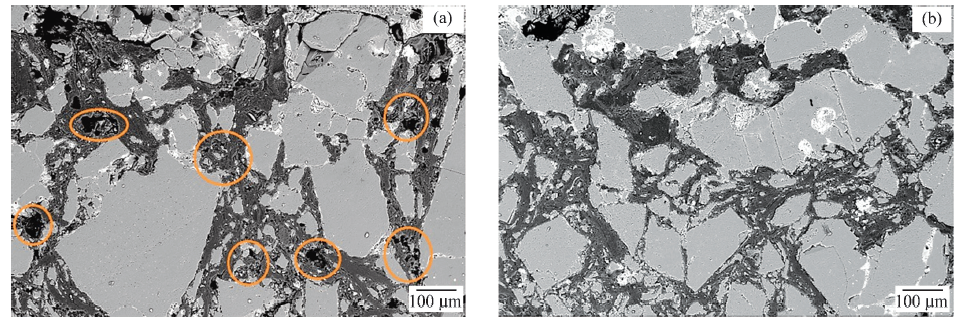

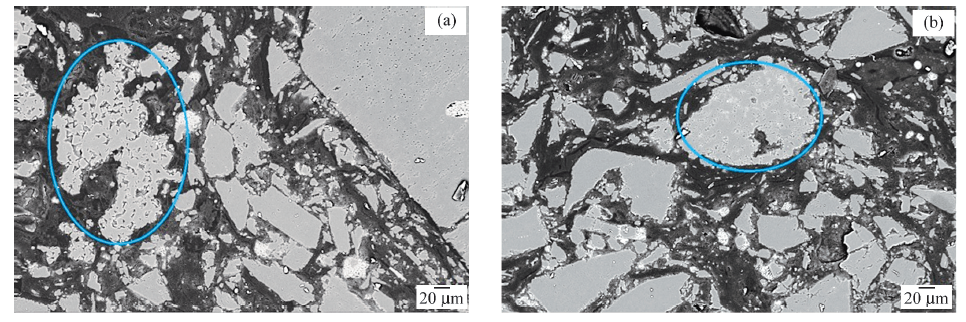

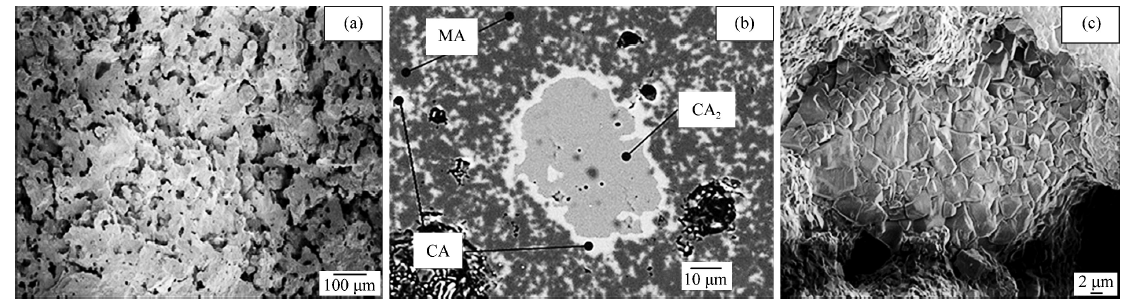

Fig. 2 MagArmour aggregate and its microstructural characteristics: porous texture (a), dispersive aluminate phases (b),and micro-crystalline spinel cluster (c)

| Brick | MgO | Al2O3 | CaO | SiO2 | Fe2O3 | C |

|---|---|---|---|---|---|---|

| MgO-C | 79.14 | 2.23 | 1.14 | 3.06 | 0.91 | 13.52 |

| MgO-MagA.-C | 76.69 | 5.66 | 1.71 | 1.92 | 0.74 | 13.28 |

Table 2 Chemical composition of metal zone bricks for comparison /mass%

| Brick | MgO | Al2O3 | CaO | SiO2 | Fe2O3 | C |

|---|---|---|---|---|---|---|

| MgO-C | 79.14 | 2.23 | 1.14 | 3.06 | 0.91 | 13.52 |

| MgO-MagA.-C | 76.69 | 5.66 | 1.71 | 1.92 | 0.74 | 13.28 |

| Brick | MgO | Al2O3 | CaO | SiO2 | Fe2O3 | C |

|---|---|---|---|---|---|---|

| MgO-C | 79.48 | 2.17 | 1.29 | 2.73 | 0.67 | 13.66 |

| MgO-MagA.-C | 79.52 | 3.88 | 1.85 | 0.62 | 0.71 | 13.42 |

Table 3 Chemical composition of slag zone bricks for comparison /mass%

| Brick | MgO | Al2O3 | CaO | SiO2 | Fe2O3 | C |

|---|---|---|---|---|---|---|

| MgO-C | 79.48 | 2.17 | 1.29 | 2.73 | 0.67 | 13.66 |

| MgO-MagA.-C | 79.52 | 3.88 | 1.85 | 0.62 | 0.71 | 13.42 |

| Items | Value |

|---|---|

| Tapping temperature /℃ | 1 620-1 650 |

| Mean holding duration /min | 100 |

| Mean tapping cycle /min | 45 |

| LF treatment /% | 95 |

| LF treating duration /min | 35-40 |

| RH treatment /% | 5 |

| RH treating duration /min | 40 |

Table 4 Working conditions of 120t refining ladle

| Items | Value |

|---|---|

| Tapping temperature /℃ | 1 620-1 650 |

| Mean holding duration /min | 100 |

| Mean tapping cycle /min | 45 |

| LF treatment /% | 95 |

| LF treating duration /min | 35-40 |

| RH treatment /% | 5 |

| RH treating duration /min | 40 |

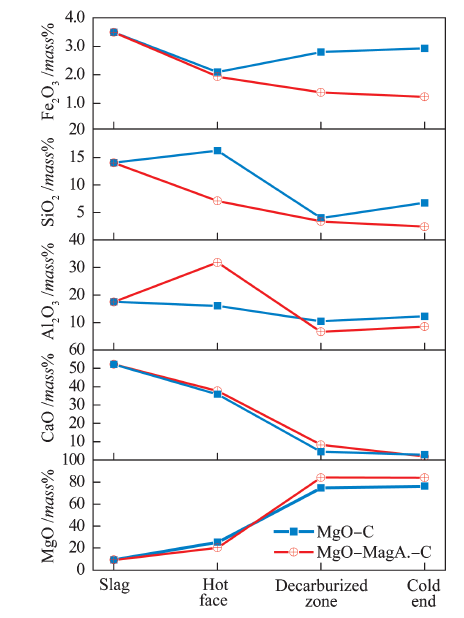

| Al2O3 | CaO | SiO2 | MgO | Fe2O3 | MnO | P2O5 | S | Others |

|---|---|---|---|---|---|---|---|---|

| 17.5 | 52.2 | 14.0 | 9.3 | 3.49 | 0.32 | 0.03 | 0.72 | 4.55 |

Table 5 Chemical composition of slag /mass%

| Al2O3 | CaO | SiO2 | MgO | Fe2O3 | MnO | P2O5 | S | Others |

|---|---|---|---|---|---|---|---|---|

| 17.5 | 52.2 | 14.0 | 9.3 | 3.49 | 0.32 | 0.03 | 0.72 | 4.55 |

| MgO | Al2O3 | SiO2 | CaO | Fe2O3 | TiO2 | |

|---|---|---|---|---|---|---|

| Dark grey phase | 85.54 | - | - | - | 15.46 | - |

| Light grey phase | - | 3.34 | 33.19 | 61.89 | 1.58 | - |

| White matrix phase | 0.77 | 6.45 | 3.30 | 41.49 | 43.11 | 4.89 |

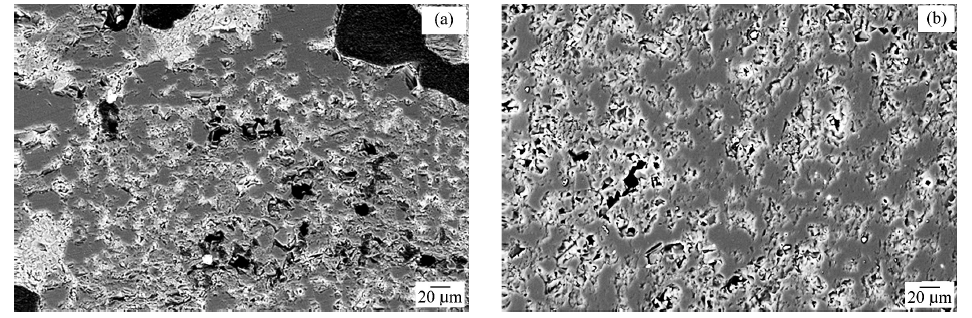

Table 6 Chemical composition of various phases in protective coating /mass%

| MgO | Al2O3 | SiO2 | CaO | Fe2O3 | TiO2 | |

|---|---|---|---|---|---|---|

| Dark grey phase | 85.54 | - | - | - | 15.46 | - |

| Light grey phase | - | 3.34 | 33.19 | 61.89 | 1.58 | - |

| White matrix phase | 0.77 | 6.45 | 3.30 | 41.49 | 43.11 | 4.89 |

| [1] | Toshihiko Emi. Steelmaking technology for the last 100 years: Toward highly efficient mass production systems for high quality steels. ISIJ International, 2015,55(1):36-66. |

| [2] | K. Goto, S. Hanagiri, K. Kohno, T. Matsui, T. Ikemoto. Progress and perspective of refractory technology. Nippon Steel Technical Report, 2013,104(8):21-25. |

| [3] | J. Poirier. A review: Influence of refractories on steel quality. Metallurgical Research and Technology, 2015,112(4):1-20. |

| [4] | Carlos Pagliosa, Paulo Vinicius Souza, Naruhiko Hama, Christoph Wöhrmeyer, Carl Zetterström, Paulo C. Evangelista. Improvement of MAC bricks with CaO-MgO-Al2O3 aggregate: a new perspective for cement application. Proceedings of Unitecr2017, Santiago, Chile, 2017: 169-172. |

| [5] | C. Wöhrmeyer, J. Y. Gao, S. Graddick, C. Parr, F. Simonin, G. Bhattacharya, M. Iiyama, P. Gehre, C. Aneziris. Protection mechanism of CMA-additive in MgO-C ladle bricks. Proceedings of 61th International Colloquium on Refractories, Aachen, Germany, 2018: 2-7. |

| [6] | C. Wöhrmeyer, J. Y. Gao, Z. Ping, C. Parr, C. G. Aneziris, P. Gehre. Corrosion mechanism of MgO-CMA-C ladle brick with high service life. Steel Research International, 2020,91(2):1-5. |

| [7] | C. Wöhrmeyer, J. Y. Gao, C. Parr, M. Szepizdyn, R. -M. Mineau, J. Zhu. Corrosion mechanism of a density-reduced steel ladle lining containing porous spinel-calcium aluminate aggregates. Ceramics, 2020(3):155-170. |

| [8] | T. Preisker, P. Gehre, G. Schmidt, C. G. Aneziris, C. Wöhrmeyer, C. Parr. Kinetics of the formation of protective slag layers on MgO-MgAl2O4-C ladle bricks determined in laboratory. Ceramics International, 2020 (46):452-459. |

| [9] | P. Gehre, T. Preisker, N. Brachhold, S. Guhl, C. Wöhrmeyer, C. Parr, C. G. Aneziris. Thermodynamic calculation and microscopic examination of liquid phase formation in MgO-C refractories contain calcium magnesium aluminate. Materials Chemistry and Physics, 2020 (256):123723. |

| [10] | A. Yamaguchi. The effect and behaviour of additives for carbon-containing refractories. Journal of the Technical Association of Refrac-tories, Japan, 2010,30(4):282-286. |

| [11] | K. Goto, B. B. Argent, W. E. Lee. Corrosion of MgO-MgAl2O4 spinel refractory bricks by calcium aluminosilicate slag. Journal of the American Ceramic Society, 1997,80(2):461-471. |

| [12] | M. Cho, G. Hong, S.-K. Lee. Corrosion of spinel clinker by CaO-Al2O3-SiO2 ladle slag. Journal of the European Ceramic Society, 2002,22(11):1783-1790. |

| [1] | WANG Li, LIU Shijie, WEI Haoyu, GUO Yanyan, GENG Shangrui, YAN Miaoxin, QIN Feng, GUO Yusen, Ma Juanjuan, DONG Binbin. Microwave-assisted Synthesis of Al4SiC4 and Its Effect on Properties of MgO-C Refractories [J]. China's Refractories, 2024, 33(1): 14-17. |

| [2] | WANG Jiaping, WU Jiguang, HUANG Zhigang, LYU Chunjiang, WANG Wenwu. Steam Oxidation Resistance Comparison of Several Silicon Carbide Refractories at Elevated Temperatures [J]. China's Refractories, 2023, 32(2): 18-23. |

| [3] | CAO Zhuang, JIA Qingwei, ZHANG Jun, ZHOU Huijun, LI Jinfeng, HUN Xianlei, YAN Leixin, QIN Hongbin, ZHANG Sanhua. Effect of Different Silica Fumes on Properties of Al2O3-SiC-C Castables for Iron Trough [J]. China's Refractories, 2023, 32(2): 31-36. |

| [4] | LIU Zhenglong, DENG Chengji, YU Chao, DING Jun, ZHU Hongxi. Effect of C@SiC Composite Powder Addition on Properties of Al2O3-SiC-C Castables for Iron Trough [J]. China's Refractories, 2022, 31(4): 39-44. |

| [5] | SHI Huiying, WANG Jiaping, WU Jiguang, HUANG Zhigang, QIN Hongbin. Steam Oxidation Resistance of Silicon Carbide Castables at Elevated Temperatures [J]. China's Refractories, 2021, 30(3): 23-27. |

| [6] | CAO Huiyan, HUANG Zhigang, ZHANG Xinhua, LIU Zhen. Research on Steam Oxidation Resistance of Si3N4-bonded SiC Refractories [J]. China's Refractories, 2020, 29(1): 44-47. |

| [7] | HUANG Zhigang*, WANG Jiaping, LI Jie, CAO Huiyan, WU Jiguang. Steam Oxidation Resistance of Nitride Bonded Silicon Carbide Refractories for Waste Incinerators at Elevated Temperatures [J]. , 2019, 28(3): 4-7. |

| [8] | Christoph WÖHRMEYER, GAO Jianying, Magali SZEPIZDYN, Fabien SIMONIN. Thermal Shock Resistance of Ladle Castables [J]. , 2018, 27(2): 7-12. |

| [9] | WEI Guoping, ZHU Boquan, LI Xiangcheng, MA Zheng. Carbonization of Ni-doped Phenol Resin Under Various Conditions [J]. , 2017, 26(2): 25-30. |

| [10] | Christoph WÖHRMEYER, Christopher PARR, Fabien SIMONIN, Bin LI, Susan LI, Simon GAO, Magali SZEPIZDYN, Jim FARRELL, Scott KNIGHTON. “In-situ Recycling”: Monolithic Ladle Repair with Shotcreting [J]. , 2015, 24(1): 44-50. |

| [11] | LIANG Feng, XUE Zhengliang, ZHAO Lei, FANG Wei, YE Linfeng, LEI Zhongxing. Replacement of Flake Graphite in Alumina-carbon Refractories by Hexagonal Boron Nitride [J]. , 2014, 23(4): 36-40. |

| [12] | XIE Zhaohui, CHEN Liugang, ZHAI Pengtao, ZHANG Yang. Effect of ZnO on Oxidation Resistance of Low Carbon MgO-C Refractories [J]. , 2014, 23(2): 7-11. |

| [13] | ZHANG Feifei, YU Renhong, ZHOU Ningsheng. Effect of Zircon Addition on Properties of Low Carbon Al2O3-C Refractories [J]. , 2014, 23(1): 38-42. |

| [14] | WANG Changchun, YE Fangbao, CHEN Huaduo, YE Xiaozhou. Effect of Al2O3-SiC Composite Powder on Properties of Al2O3-SiC-C Bricks [J]. , 2014, 23(1): 32-37. |

| [15] | DENG Chengji,YU Chao,ZHU Hongxi, KUANG Jianlei, YUAN Wenjie. Effect of Al on Al4SiC4-Al4O4C Composite Synthesized from Kaolinite Grog [J]. China's Refractories, 2012, 21(3): -. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||