China's Refractories ›› 2020, Vol. 29 ›› Issue (2): 11-20.DOI: 10.19691/j.cnki.1004-4493.2020.02.003

• Original article • Previous Articles Next Articles

Slag Resistance of Refractories for Direct Reduction of Laterite Nickel Ores in Rotary Kilns

CHEN Wei1,2,*( ), ZHANG Xiaohui1, ZHANG Haijun2

), ZHANG Xiaohui1, ZHANG Haijun2

- 1 Sinosteel Luoyang Institute of Refractories Research Co., Ltd., Luoyang 471039, China

2 Wuhan University of Science and Technology, Wuhan 430081, China

-

Revised:2021-05-13Online:2020-06-15Published:2020-06-15 -

Contact:CHEN Wei -

About author:Chen Wei, born in 1983, obtained his bachelor's degree with the major of materials science and engineering from Xi'an University of Architecture and Technology in 2006 and master's degree with the major of materials science from Wuhan University of Science and Technology in 2018. Since 2006, he has been working in Sinosteel Luoyang Institute of Refractories Research Co., Ltd. At present, he is the deputy executive general manager of Sinosteel Nanjing Environmental Materials Technology Research Institute Co., Ltd., (in preparation) and the vice director of the National Quality Supervision and Inspection Center for Refractories. His research interest is the performance test and characterization of refractories. He, as the group leader, has set three national standards as well as one industry standard on refractory testing methods.

Cite this article

CHEN Wei, ZHANG Xiaohui, ZHANG Haijun. Slag Resistance of Refractories for Direct Reduction of Laterite Nickel Ores in Rotary Kilns[J]. China's Refractories, 2020, 29(2): 11-20.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2020.02.003

| Samples | AP /% | BD /(g · cm-3) | CCS /MPa | RUL /℃ | HMOR /MPa | Thermal shock resistance (1 100 ℃, water quenching) /cycles |

|---|---|---|---|---|---|---|

| High alumina bricks | 19.1 | 138 | 1 550 | |||

| Corundum bricks | 18.6 | 3.22 | 111 | >1 700 | ≥6 | |

| High alumina silicon carbide bricks | 19.8 | 2.70 | 93.4 | |||

| Chrome corundum bricks | 3.45 | 335 | ||||

| Chrome corundum castable | 3.32 | 151 | ||||

| Spinel chrome corundum bricks | 3.43 | 220 | 17.4 (1 450 ℃×0.5 h) | >13 | ||

| Magnesium aluminate spinel bricks | 2.93 | 61.8 | >1 700 | >10 | ||

| Magnesia chrome bricks | 3.28 | 72.1 | 8.2 (1 450 ℃×0.5 h) | >10 | ||

| Magnesia alumina chrome composite spinel bricks | 3.03 | 61.1 | ||||

| Silicon nitride bonded silicon carbide bricks | 16 | 2.66 | 190 | 61.1 (1 400 ℃×0.5 h) |

Table 1 Physical properties of test bricks

| Samples | AP /% | BD /(g · cm-3) | CCS /MPa | RUL /℃ | HMOR /MPa | Thermal shock resistance (1 100 ℃, water quenching) /cycles |

|---|---|---|---|---|---|---|

| High alumina bricks | 19.1 | 138 | 1 550 | |||

| Corundum bricks | 18.6 | 3.22 | 111 | >1 700 | ≥6 | |

| High alumina silicon carbide bricks | 19.8 | 2.70 | 93.4 | |||

| Chrome corundum bricks | 3.45 | 335 | ||||

| Chrome corundum castable | 3.32 | 151 | ||||

| Spinel chrome corundum bricks | 3.43 | 220 | 17.4 (1 450 ℃×0.5 h) | >13 | ||

| Magnesium aluminate spinel bricks | 2.93 | 61.8 | >1 700 | >10 | ||

| Magnesia chrome bricks | 3.28 | 72.1 | 8.2 (1 450 ℃×0.5 h) | >10 | ||

| Magnesia alumina chrome composite spinel bricks | 3.03 | 61.1 | ||||

| Silicon nitride bonded silicon carbide bricks | 16 | 2.66 | 190 | 61.1 (1 400 ℃×0.5 h) |

| Test bricks | Maximum corrosion depth |

|---|---|

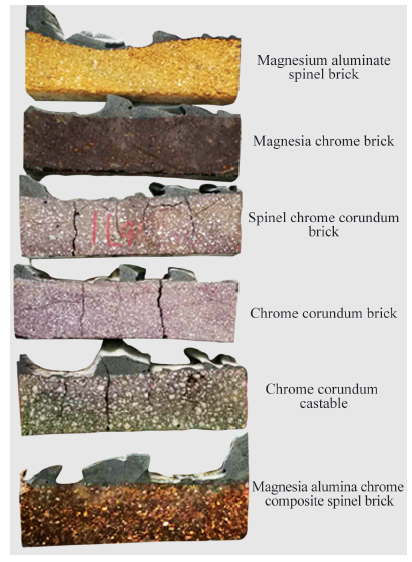

| Magnesium aluminate spinel brick | 18.6 |

| Magnesia chrome brick | 7.7 |

| Spinel chrome corundum brick | 7.2 |

| Chrome corundum brick | 4.4 |

| Chrome corundum castable | 5.9 |

| Magnesia alumina chrome composite spinel brick | 4.7 |

Table 2 Maximum corrosion depth of refractories /mm

| Test bricks | Maximum corrosion depth |

|---|---|

| Magnesium aluminate spinel brick | 18.6 |

| Magnesia chrome brick | 7.7 |

| Spinel chrome corundum brick | 7.2 |

| Chrome corundum brick | 4.4 |

| Chrome corundum castable | 5.9 |

| Magnesia alumina chrome composite spinel brick | 4.7 |

| Na2O | MgO | Al2O3 | SiO2 | CaO | Cr2O3 | MnO | Fe2O3 | NiO |

|---|---|---|---|---|---|---|---|---|

| 0.34 | 10.62 | 8.80 | 12.75 | 0.36 | 4.50 | 1.05 | 60.78 | 0.80 |

Table 3 Chemical composition of slag layer /mass%

| Na2O | MgO | Al2O3 | SiO2 | CaO | Cr2O3 | MnO | Fe2O3 | NiO |

|---|---|---|---|---|---|---|---|---|

| 0.34 | 10.62 | 8.80 | 12.75 | 0.36 | 4.50 | 1.05 | 60.78 | 0.80 |

| Na2O | MgO | Al2O3 | SiO2 | CaO | Cr2O3 | MnO | Fe2O3 | NiO |

|---|---|---|---|---|---|---|---|---|

| 0.32 | 9.16 | 18.53 | 13.31 | 0.29 | 7.58 | 0.95 | 48.96 | 0.89 |

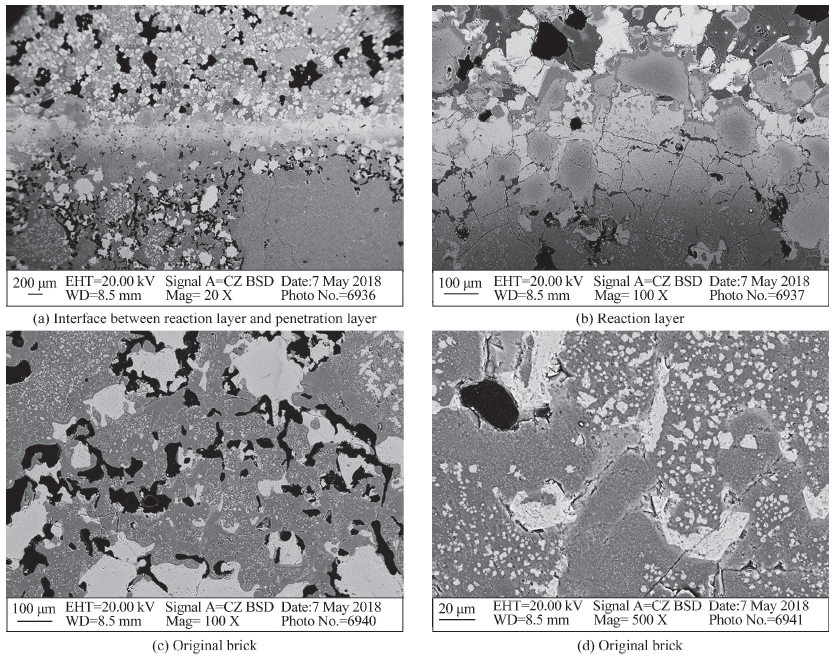

Table 4 Chemical composition of slag layer of spinel chrome corundum brick /mass%

| Na2O | MgO | Al2O3 | SiO2 | CaO | Cr2O3 | MnO | Fe2O3 | NiO |

|---|---|---|---|---|---|---|---|---|

| 0.32 | 9.16 | 18.53 | 13.31 | 0.29 | 7.58 | 0.95 | 48.96 | 0.89 |

| Depth /mm | MgO | Al2O3 | SiO2 | P2O5 | Cr2O3 | Fe2O3 | ZrO2 |

|---|---|---|---|---|---|---|---|

| 0 | 1.51 | 58.59 | 8.23 | 1.08 | 18.21 | 11.17 | - |

| 3 | 2.85 | 53.77 | 10.76 | 0.80 | 17.92 | 9.26 | 3.21 |

| 6 | 3.34 | 52.48 | 6.82 | 0.73 | 24.67 | 6.62 | 3.82 |

| 9 | 2.02 | 59.30 | 10.02 | 1.79 | 16.30 | 5.19 | 3.46 |

| 12 | 3.94 | 56.12 | 8.46 | 1.75 | 17.84 | 6.56 | 4.02 |

| 15 | 3.88 | 54.42 | 5.04 | 3.29 | 20.74 | 6.13 | 4.61 |

| 20 | 5.43 | 52.63 | 3.27 | 4.06 | 18.65 | 1.91 | 3.92 |

Table 5 EDS results of spinel chrome corundum brick along permeation direction /mass%

| Depth /mm | MgO | Al2O3 | SiO2 | P2O5 | Cr2O3 | Fe2O3 | ZrO2 |

|---|---|---|---|---|---|---|---|

| 0 | 1.51 | 58.59 | 8.23 | 1.08 | 18.21 | 11.17 | - |

| 3 | 2.85 | 53.77 | 10.76 | 0.80 | 17.92 | 9.26 | 3.21 |

| 6 | 3.34 | 52.48 | 6.82 | 0.73 | 24.67 | 6.62 | 3.82 |

| 9 | 2.02 | 59.30 | 10.02 | 1.79 | 16.30 | 5.19 | 3.46 |

| 12 | 3.94 | 56.12 | 8.46 | 1.75 | 17.84 | 6.56 | 4.02 |

| 15 | 3.88 | 54.42 | 5.04 | 3.29 | 20.74 | 6.13 | 4.61 |

| 20 | 5.43 | 52.63 | 3.27 | 4.06 | 18.65 | 1.91 | 3.92 |

| Depth /mm | MgO | Al2O3 | SiO2 | P2O5 | Cr2O3 | MnO2 | Fe2O3 | NiO |

|---|---|---|---|---|---|---|---|---|

| Slag | 11.08 | 16.36 | 11.61 | - | 4.87 | 0.88 | 54.13 | 0.84 |

| 0 | 1.83 | 55.03 | 10.53 | - | 14.32 | 0.52 | 17.05 | - |

| 5 | 0.64 | 61.17 | 12.14 | 0.67 | 19.85 | - | 4.78 | - |

| 10 | 0.89 | 53.93 | 11.97 | 2.09 | 23.74 | - | 6.14 | - |

| 15 | 0.94 | 54.28 | 7.83 | 4.13 | 26.24 | - | 4.79 | - |

| Original brick | 1.28 | 53.59 | 1.89 | 0.80 | 35.52 | - | 6.36 | - |

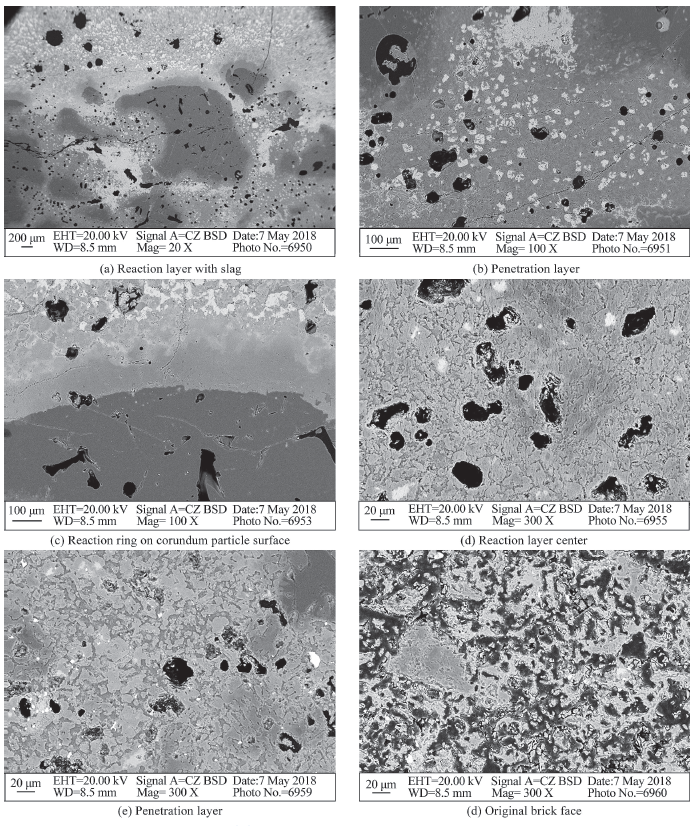

Table 6 EDS results of chrome corundum brick along permeation direction /mass%

| Depth /mm | MgO | Al2O3 | SiO2 | P2O5 | Cr2O3 | MnO2 | Fe2O3 | NiO |

|---|---|---|---|---|---|---|---|---|

| Slag | 11.08 | 16.36 | 11.61 | - | 4.87 | 0.88 | 54.13 | 0.84 |

| 0 | 1.83 | 55.03 | 10.53 | - | 14.32 | 0.52 | 17.05 | - |

| 5 | 0.64 | 61.17 | 12.14 | 0.67 | 19.85 | - | 4.78 | - |

| 10 | 0.89 | 53.93 | 11.97 | 2.09 | 23.74 | - | 6.14 | - |

| 15 | 0.94 | 54.28 | 7.83 | 4.13 | 26.24 | - | 4.79 | - |

| Original brick | 1.28 | 53.59 | 1.89 | 0.80 | 35.52 | - | 6.36 | - |

| Depth /mm | Na2O | MgO | Al2O3 | SiO2 | CaO | P2O5 | Cr2O3 | Fe2O3 |

|---|---|---|---|---|---|---|---|---|

| Slag | 0.38 | 8.58 | 13.17 | 17.67 | 0.36 | - | 6.11 | 52.24 |

| 0 | 0.40 | 1.03 | 57.52 | 8.06 | 0.37 | - | 22.62 | 10.00 |

| 5 | 0.74 | 0.53 | 54.86 | 10.36 | 2.01 | - | 25.37 | 6.14 |

| 10 | 0.67 | 0.19 | 59.30 | 5.68 | 3.05 | 0.63 | 26.60 | 3.87 |

| 15 | 0.67 | - | 55.14 | 4.34 | 4.68 | 1.82 | 28.95 | 4.17 |

| 20 | - | - | 54.52 | 0.59 | 2.79 | 0.74 | 37.56 | 3.80 |

Table 7 EDS results of chrome corundum castable along permeation direction /mass%

| Depth /mm | Na2O | MgO | Al2O3 | SiO2 | CaO | P2O5 | Cr2O3 | Fe2O3 |

|---|---|---|---|---|---|---|---|---|

| Slag | 0.38 | 8.58 | 13.17 | 17.67 | 0.36 | - | 6.11 | 52.24 |

| 0 | 0.40 | 1.03 | 57.52 | 8.06 | 0.37 | - | 22.62 | 10.00 |

| 5 | 0.74 | 0.53 | 54.86 | 10.36 | 2.01 | - | 25.37 | 6.14 |

| 10 | 0.67 | 0.19 | 59.30 | 5.68 | 3.05 | 0.63 | 26.60 | 3.87 |

| 15 | 0.67 | - | 55.14 | 4.34 | 4.68 | 1.82 | 28.95 | 4.17 |

| 20 | - | - | 54.52 | 0.59 | 2.79 | 0.74 | 37.56 | 3.80 |

| Depth /mm | MgO | Al2O3 | SiO2 | CaO | MnO2 | Cr2O3 | Fe2O3 | NiO |

|---|---|---|---|---|---|---|---|---|

| Slag | 10.62 | 10.82 | 12.09 | 0.32 | 0.86 | 6.64 | 57.31 | 0.98 |

| 0 | 16.08 | 8.62 | 3.05 | - | 0.77 | 4.57 | 65.11 | 1.81 |

| 2 | 53.42 | 2.16 | 2.20 | 0.24 | 0.44 | 1.21 | 38.65 | 1.67 |

| 5 | 78.70 | 7.71 | 2.04 | 2.26 | - | 5.38 | 3.91 | - |

| 10 | 81.40 | 3.41 | 3.25 | 3.34 | - | 5.12 | 3.47 | - |

| 15 | 83.92 | 3.15 | 2.60 | 2.39 | - | 4.30 | 3.63 | - |

| Original brick | 83.30 | 3.58 | 2.30 | 3.67 | - | 3.41 | 3.74 | - |

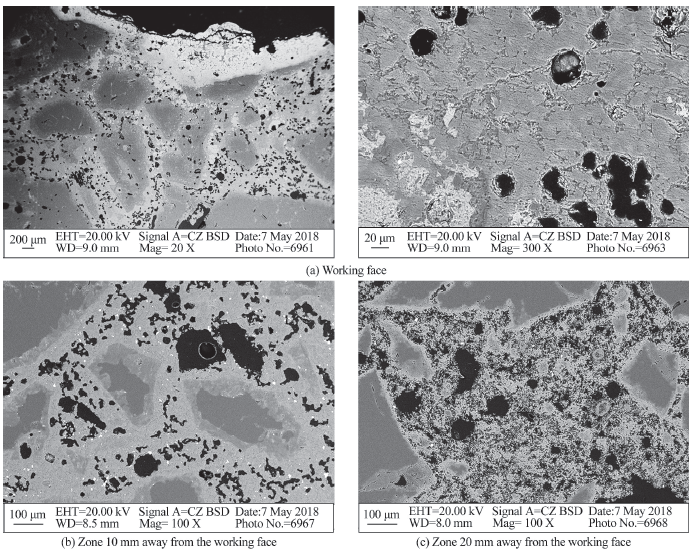

Table 8 EDS results of magnesia alumina chrome composite spinel brick along permeation direction /mass%

| Depth /mm | MgO | Al2O3 | SiO2 | CaO | MnO2 | Cr2O3 | Fe2O3 | NiO |

|---|---|---|---|---|---|---|---|---|

| Slag | 10.62 | 10.82 | 12.09 | 0.32 | 0.86 | 6.64 | 57.31 | 0.98 |

| 0 | 16.08 | 8.62 | 3.05 | - | 0.77 | 4.57 | 65.11 | 1.81 |

| 2 | 53.42 | 2.16 | 2.20 | 0.24 | 0.44 | 1.21 | 38.65 | 1.67 |

| 5 | 78.70 | 7.71 | 2.04 | 2.26 | - | 5.38 | 3.91 | - |

| 10 | 81.40 | 3.41 | 3.25 | 3.34 | - | 5.12 | 3.47 | - |

| 15 | 83.92 | 3.15 | 2.60 | 2.39 | - | 4.30 | 3.63 | - |

| Original brick | 83.30 | 3.58 | 2.30 | 3.67 | - | 3.41 | 3.74 | - |

| [1] |

Guang Chu, Sijia Zhao, Tianzu Yang. Extraction of nickel from molybdenum leaching residue of metalliferous black shale by segregation roasting and acid leaching. Journal of Central South University, 2012,19(2):340-346.

DOI URL |

| [2] | Guo Wenxi, Su Zhenggang, Ma Yuchi, Zhang Weijun. Research and design for vertical reduction furnace of laterite nickel ore. Energy for Metallurgical Industry (in Chinese), 2015,34(6):40-41, 61. |

| [3] | Li Xiaobo, Xuan Lu. Experimental study on reduction roasting of limonitic laterite-nickel ore. Hydrometallurgy of China (in Chinese), 2016,35(3):205-208. |

| [4] | Chen Jingyou, Tan Juming. Technology of pyrometallurgical ferronickel with nickel-bearing laterite. Ferro-Alloys (in Chinese), 2008,39(3):13-15. |

| [5] | Sun Chengcai, Xu Xingqi, Lv Youcheng, Li Fuhua, Wang Lin. Relationship between chemical components of laterite nickel deposite. Shandong Land and Resources (in Chinese), 2015,31(4):50-52. |

| [1] | Valeriy V. MARTYNENKO, Iryna G. SHULYK, Yuliya Ye. MISHNYOVA, Tetyana G. TYSHYNA. Investigation of Microstructure and Phase Composition of Chromic Oxide, AZS/Cr and High-alumina Refractories after Exposure of Basalt and Aluminaboronsilicate Glasses Melts [J]. China's Refractories, 2024, 33(1): 1-6. |

| [2] | WANG Li, LIU Shijie, WEI Haoyu, GUO Yanyan, GENG Shangrui, YAN Miaoxin, QIN Feng, GUO Yusen, Ma Juanjuan, DONG Binbin. Microwave-assisted Synthesis of Al4SiC4 and Its Effect on Properties of MgO-C Refractories [J]. China's Refractories, 2024, 33(1): 14-17. |

| [3] | HU Chen, WANG Xing, LIU Zhenglong, DING Jun, YU Chao, DENG Chengji. Effect of ZrC Modified Graphite on Structure and Properties of Low-carbon Al2O3-C Refractories [J]. China's Refractories, 2024, 33(1): 18-22. |

| [4] | DU Juan, GUO Huishi, YANG Jialin, LI Wenfeng, GUI Yanghai, ZHAO Zhiqiang, LIU Yingfan. Effects of Al2O3-SiO2 Raw Material Types on Properties of Anorthite Based Insulation Refractories [J]. China's Refractories, 2024, 33(1): 23-27. |

| [5] | ZOU Xin, CHEN Ping’an, XU Guangping, LI Xiangcheng, ZHU Yingli, ZHU Boquan. Sintering Densification of Boron Carbide Materials and Their Research Progress [J]. China's Refractories, 2023, 32(4): 22-27. |

| [6] | CHEN Yang, DENG Chengji, DING Jun, YU Chao, LOU Xiaoming. Effect of Ferric Nitrate Loading Mode on Properties of Si3N4 Composite MgO-C Refractories Prepared by Nitridation [J]. China's Refractories, 2023, 32(3): 6-9. |

| [7] | ZHOU Lianzhuo, WANG Zhoufu, WANG Xitang, LIU Hao, MA Yan, QUAN Zhenghuang. Effect of Al Powder and Si Powder Additions on Structure and Properties of Unburned Magnesium Aluminate Spinel Refractories [J]. China's Refractories, 2023, 32(3): 14-19. |

| [8] | ZHANG Hongrui, CHEN Liugang. Binder Effect on Properties of Cr2O3-bearing Corundum-based Refractory Castables [J]. China's Refractories, 2023, 32(3): 36-41. |

| [9] | WANG Jiaping, WU Jiguang, HUANG Zhigang, LYU Chunjiang, WANG Wenwu. Steam Oxidation Resistance Comparison of Several Silicon Carbide Refractories at Elevated Temperatures [J]. China's Refractories, 2023, 32(2): 18-23. |

| [10] | CAO Zhuang, JIA Qingwei, ZHANG Jun, ZHOU Huijun, LI Jinfeng, HUN Xianlei, YAN Leixin, QIN Hongbin, ZHANG Sanhua. Effect of Different Silica Fumes on Properties of Al2O3-SiC-C Castables for Iron Trough [J]. China's Refractories, 2023, 32(2): 31-36. |

| [11] | XU Guotao, ZHAO Yuan, WU Jie, ZHANG Honglei, LIU Li, ZHANG Yanwen, ZHOU Wangzhi. Discussion on Abnormal Corrosion and Material Selection of Hot Iron Ladles with Steel Scrap Addition [J]. China's Refractories, 2023, 32(1): 1-5. |

| [12] | AN Yi, LIU Hao, WANG Zhoufu, MA Yan, WANG Xitang. Research on Corrosion Resistance of Checker Bricks in Regenerators of Glass Furnaces [J]. China's Refractories, 2023, 32(1): 20-24. |

| [13] | Ana Valéria de Sousa COSTA, Belmira Benedita de LIMA-KUHN, Antonio Renato BIGANSOLLI. Post-mortem Microstructural Study of Aluminous Refractory Brick Used in Channels of Blast Furnaces [J]. China's Refractories, 2023, 32(1): 40-43. |

| [14] | LUO Huaming, CAI Binli, YUAN Zhenqiang, ZUO Genliang, Zhang Jingzheng, WANG Fengyu, LI Jinyu, WEI Yingfeng, SUN Huochang, ZHAN Huasheng. Application and Hydration Resistance of SiC Refractories for Water-cooled Wall of Waste Incinerators [J]. China's Refractories, 2022, 31(2): 12-16. |

| [15] | LUO Huaming, CAI Binli, ZUO Genliang, ZHANG Guohua, WANG Sheng, FAN Mingming, CHEN Kun, ZHAN Huasheng. Typical Refractories Design of Rotary Kiln Hazardous Waste Incineration System [J]. China's Refractories, 2022, 31(2): 30-34. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||