China's Refractories ›› 2020, Vol. 29 ›› Issue (2): 1-5.DOI: 10.19691/j.cnki.1004-4493.2020.02.001

• Original article • Next Articles

High Temperature Interactions of Chrome Oxide Free Refractories with Coal Slag Under Simulated Gasification Conditions

ZHAO Shixian*( ), LI Hongxia, SUN Honggang, CAI Binli, WANG Lan, KANG Yina

), LI Hongxia, SUN Honggang, CAI Binli, WANG Lan, KANG Yina

- Sinosteel Luoyang Institute of Refractories Research Co., Ltd., Luoyang 471039, China

-

Revised:2021-05-13Online:2020-06-15Published:2020-06-15 -

Contact:ZHAO Shixian -

About author:Zhao Shixian, born in 1981, obtained his bachelor's degree and Ph. D in material science from Gansu University of Technology in 2004 and Beijing University of Technology in 2010, respectively. Now he is working in Sinosteel Luoyang Institute of Refractories Research Co., Ltd. and researching on experimental and thermodynamic evaluation of stability and corrosion of refractory materials in metals and molten slags.

Cite this article

ZHAO Shixian, LI Hongxia, SUN Honggang, CAI Binli, WANG Lan, KANG Yina. High Temperature Interactions of Chrome Oxide Free Refractories with Coal Slag Under Simulated Gasification Conditions[J]. China's Refractories, 2020, 29(2): 1-5.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2020.02.001

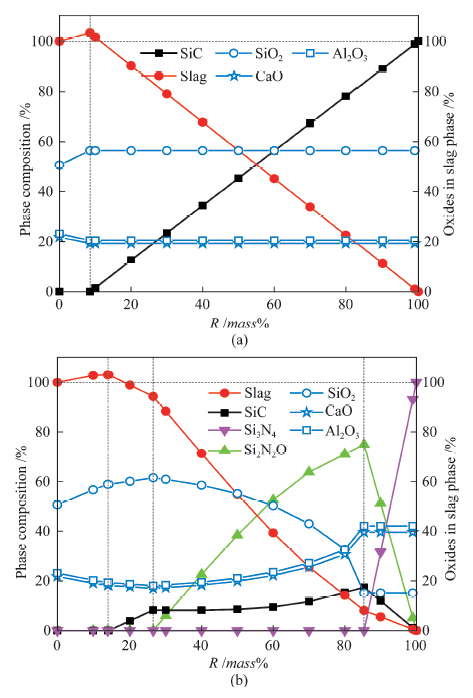

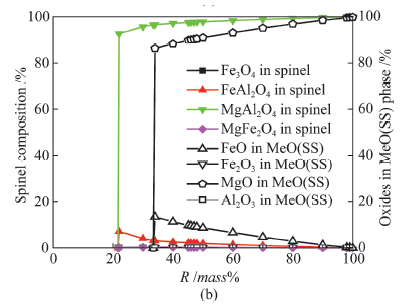

Fig. 2 Thermodynamic calculated results after reaction of MgO-Al2O3-ZrO2 brick with coal slag: (a) main phases, (b) composition in spinel and MeO solid solution (R=refractory/(refractory+slag))

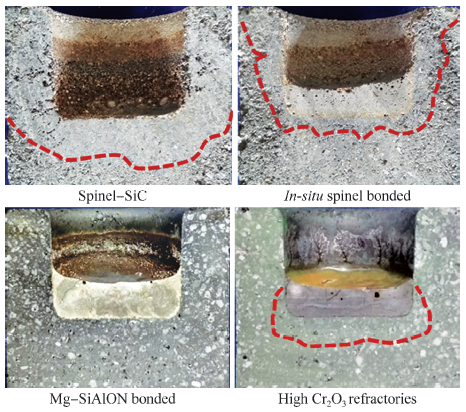

| Sample | BD /(g · cm-3) | AP /% | CMOR /MPa |

|---|---|---|---|

| Spinel-SiC | 2.72 | 18.3 | 7.1 |

| In-situ spinel bonded | 2.73 | 16.9 | 10.9 |

| Mg-SiAlON bonded | 2.58 | 20.0 | 17.0 |

Table 1 Properties of in-situ spinel bonded and Mg-SiAlON bonded spinel-SiC materials

| Sample | BD /(g · cm-3) | AP /% | CMOR /MPa |

|---|---|---|---|

| Spinel-SiC | 2.72 | 18.3 | 7.1 |

| In-situ spinel bonded | 2.73 | 16.9 | 10.9 |

| Mg-SiAlON bonded | 2.58 | 20.0 | 17.0 |

| [1] |

Kyeising Kwong, Art Petty, James Bennett, Rick Krabbe, Hugh Thomas. Wear mechanisms of chromia refractories in slagging gasifiers. International Journal of Applied Ceramic Technology, 2007,4(6):503-513.

DOI URL |

| [2] |

Jinichiro Nakano, Seetharaman Sridhar, James Bennett, Kyei-Sing Kwong, Tyler Moss. Interactions of refractory materials with molten gasifier slags. International Journal of Hydrogen Energy, 2011,36(7):4595-4604.

DOI URL |

| [3] | Obana T. Trend of chrome-free refractory materials. Journal of Technology Association Refractory Japanese, 2010,30(4):243-249. |

| [4] | Hemrick JG, Armstrong BL, Rodrigues-Schroer A, Colavito, Smith JD, O’Hara K. Spinel-based refractories for improved performance in coal gasification environments. Proceedings of UNITECR 2013, Victoria, BC,Canada, 2013: 10-13. |

| [5] | Bennett JP. Low chrome/chrome free refractories for slagging gasifiers. An Industry Perspective, US DOE/NETL Report 119. 2006: 200-206. |

| [6] |

Gehre P, Aneziris CG, Veres D, Parr C, Fryda H, Neuroth M. Improved spinel-containing refractory castables for slagging gasifiers. Journal of the European Ceramic Society. 2013,33(6):1077-1086.

DOI URL |

| [7] |

Gehre P, Aneziris CG, Berek H, Parr C, Reinmöller M. Corrosion of magnesium aluminate spinel-rich refractories by sulphur-containing slag. Journal of the European Ceramic Society. 2015,35(5):1613-1620.

DOI URL |

| [8] | Sömiya S, Inomata Y. Silicon Carbide Ceramics-1: Fundamental and Solid Reaction. Dordrecht: Springer Netherlands, 1991. |

| [9] | Sömiya S, Mitomo M, Yoshimura M. Silicon Nitride-1. New York: Elsevier Science Publishers, 1991. |

| [10] | Zhao Shixian, Cai Binli, Li Pengtao, Sun Honggang, Wang Gang. Thermodynamic evaluation of Cr2O3-Al2O3 refractory corrosion by smelting reduction ironmaking slag. China’s Refractories, 2015,24(2):6-10. |

| [1] | Burhanuddin, Harald HARMUTH. Effect of Slag Basicity on Alumina Dissolution and Diffusivity: A High-temperature Confocal Laser Scanning Microscopy Study [J]. China's Refractories, 2024, 33(2): 27-34. |

| [2] | LYU Chunjiang, CHANG Cheng, HUANG Yifei, CAO Huiyan, LI Jie, ZHU Chong. Preparation and Properties of SiC Assembled Large Block for Blast Furnace Tuyeres [J]. China's Refractories, 2023, 32(4): 1-7. |

| [3] | LIU Chenchen, HUANG Ao, NIE Jianhua, GU Huazhi, QIN Chuanjiang, Lidah Mpoli NACHILIMA. Corrosion Mechanism of Alumina-magnesia Dry Materials for Smelting Manganese/chromium Steel in Coreless Medium Frequency Induction Furnaces [J]. China's Refractories, 2023, 32(4): 8-15. |

| [4] | XU Linlin, LIU Zhao, WANG Jiezeng, CHEN Songlin, LIU Xijun. Corrosion of Basic Refractories for Glass Tanks Using Petrol Coke and Countermeasures [J]. China's Refractories, 2023, 32(3): 1-5. |

| [5] | TIAN Chen, ZHI Jianjun, GAN Feifang, FAN Zhengjie, GAO Hua, YUAN Lei, LIU Guoqi, YU Jingkun, LI Hongxia. Analysis of Corrosion Behavior of ZrO2-C Slag-line Materials in Continuous Casting [J]. China's Refractories, 2023, 32(3): 10-13. |

| [6] | ZHANG Hongrui, CHEN Liugang. Binder Effect on Properties of Cr2O3-bearing Corundum-based Refractory Castables [J]. China's Refractories, 2023, 32(3): 36-41. |

| [7] | FAN Muxu, HOU Xiaojing, FENG Zhiyuan, WANG Han, LIU Pengcheng, SHI Gan. Alkali Vapor Corrosion of Different Refractories at High Temperatures [J]. China's Refractories, 2023, 32(2): 24-30. |

| [8] | AN Yi, LIU Hao, WANG Zhoufu, MA Yan, WANG Xitang. Research on Corrosion Resistance of Checker Bricks in Regenerators of Glass Furnaces [J]. China's Refractories, 2023, 32(1): 20-24. |

| [9] | WANG Jingran, CHEN Xinming, KE Changming, ZHANG Jinhua, LIU Xuexin, LI Wen. Rheological and Sintering Properties of Two Kinds of Corundum-spinel Micropowders [J]. China's Refractories, 2022, 31(4): 7-11. |

| [10] | CAO Huiyan, ZHANG Xinhua, HUANG Yifei, WANG Wenwu, WU Jiguang, BU Xiangjuan, XU Haiyang. Influence of Graphite on Molten-alkali Corrosion Resistance for β-SiAlON-SiC Materials [J]. China's Refractories, 2022, 31(4): 22-27. |

| [11] | HAO Xian, LIU Guoqi, LI Zhixing, XU Chaojie, ZHANG Jianwei, LI Yong, LI Hongyu, LI Hongxia, FU Baoquan. Effect of Al-Si Alloy Addition on Properties of Fused Spinel Carbon Materials [J]. China's Refractories, 2022, 31(4): 45-52. |

| [12] | ZHU Shaojun. Damage Mechanism and Countermeasures of Al2O3-SiC-C Refractories Under Extreme Conditions [J]. China's Refractories, 2022, 31(2): 7-11. |

| [13] | Jens FRUHSTORFER, Steffen DUDCZIG, Leandro SCHÖTTLER, Christos G. ANEZIRIS. Corrosion of Alumina and Mullite Based Refractories by an Ingot Casting Steel [J]. , 2018, 27(1): 14-19. |

| [14] | ZOU Yang, GU Huazhi, HUANG Ao, ZHANG Meijie. Comparative Study of Lightweight Corundum with Different Microstructures and Its Effect on Slag Resistance of Al2O3-MgO Castables [J]. , 2017, 26(4): 17-23. |

| [15] | FAN Duncheng, ZHANG Yuyan, NI Wen. Corrosion and Penetration Resistance of Corundum Bricks to High Phosphorus Oolitic Hematite Reducing Materials [J]. , 2017, 26(3): 32-37. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||