| [1] |

W. E. Lee, W. Vieira, S. Zhang, K. Ghanbari Ahari, H. Sarpoolaky, C. Parr. Castable refractory concretes. International Materials Reviews, 2001, 46(3):145-167.

DOI

URL

|

| [2] |

V. Antonovič, J. Keriene, R. Boris, M. Aleknevičius. The effect of temperature on the formation of the hydrated calcium aluminate cement structure. Procedia Engineering, 2013, 57:99-106.

DOI

URL

|

| [3] |

Wang Chuanhui, Ye Guotian. On the anomalous setting behavior of calcium aluminate cement. Naihuo Cailiao (Refractories, in Chinese), 1997, 31(4):235-237.

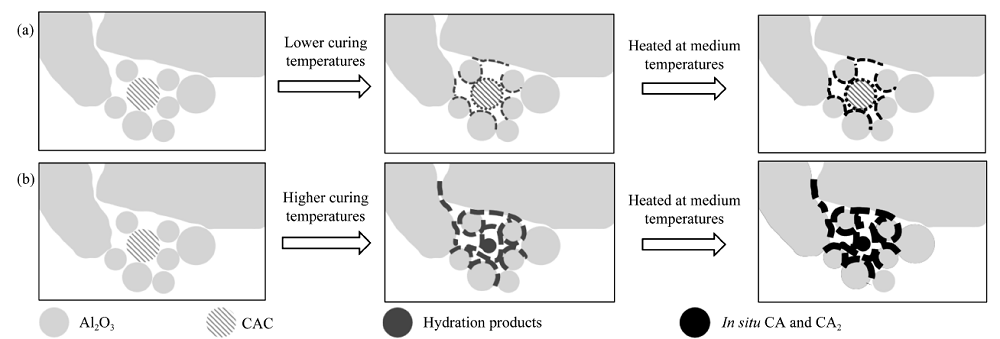

|

| [4] |

N. Ukrainczyk. Kinetic modeling of calcium aluminate cement hydration. Chemical Engineering Science, 2010, 65(20):5605-5614.

DOI

URL

|

| [5] |

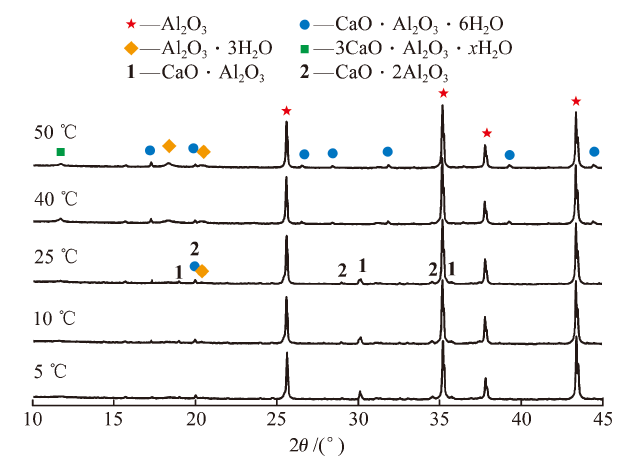

Xuejun Shang, Guotian Ye, Yaqian Zhang, Huanhuan Li, Dan Hou. Effect of micro-sized alumina powder on the hydration products of calcium aluminate cement at 40 °C. Ceramics International, 2016, 42(13):14391-14394.

DOI

URL

|

| [6] |

Shang Xuejun, Hou Dan, Tang Wei, Zhang Chuanyin, Wang Qingfeng, Ye Guotian. Effect of alumina micropowder on anomalous hydration behaviour of calcium aluminate cement. Naihuo Cailiao (Refractories, in Chinese), 2016, 50(4):252-255.

|

| [7] |

Wang Qingfeng, Ye Guotian, Li Kunpeng, Song Xiujuan, Yang Xiao. Effect of microsilica on chemical bond of calcium aluminate cement bonded corundum castables at low and intermediate temperatures. Naihuo Cailiao (Refractories, in Chinese), 2014, 48(6):409-413.

|

| [8] |

Li Zhigang, Ye Fangbao, Zhang Yu. Effect of nano calcium carbonate on strength and microstructure of corundum-based castable. Naihuo Cailiao (Refractories, in Chinese), 2009, 43(1):5-9.

|

| [9] |

I. R. Oliveira, V. C. Pandolfelli. Does a tiny amount of dispersant make any change to refractory castable properties? Ceramics International, 2010, 36(1):79-85.

DOI

URL

|

| [10] |

Yulong Wang, Boquan Zhu, Xiangcheng Li, Ping’an Chen. Effect of dispersants on the hydrate morphologies of spinel-containing calcium aluminate cement and on the properties of refractory castables. Ceramics International, 2016, 42(1):711-720.

DOI

URL

|

| [11] |

Li Ye, Liu Kun, Zhang Peixiong, Ding Dafei, Shang Xuejun, Chen Liugang, Ye Guotian. Influence of calcium aluminate cement hydration products on hydration of calcium aluminate cement. Naihuo Cailiao (Refractories, in Chinese), 2018, 52(4):246-249.

|

| [12] |

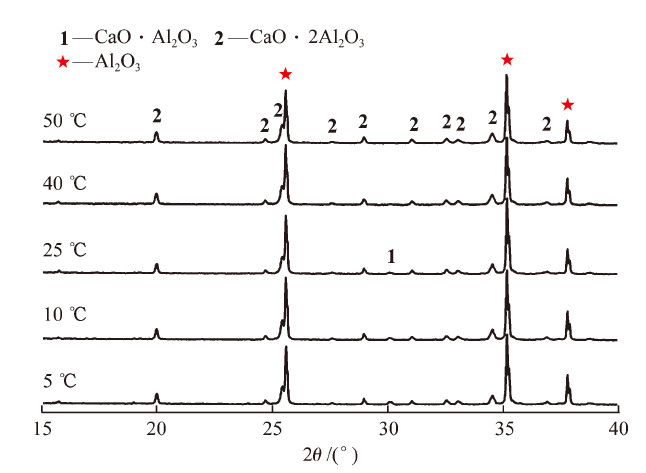

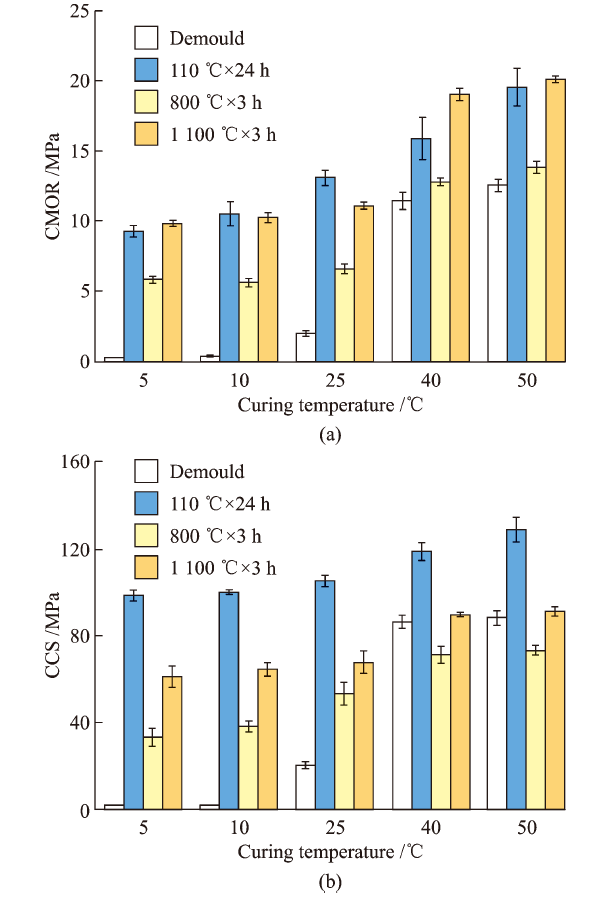

Peixiong Zhang, Na Li, Jian Luan, Song Gao, Guotian Ye. Relationship between the strength and microstructure of CAC-bonded castables under intermediate temperatures. Ceramics International, 2020, 46(1):888-892.

DOI

URL

|

| [13] |

Zhou Ningsheng, Liu Min, Zhang Sanhua. Thermal behavior in relation to different bindings of alumina based castables from 20 to 1 000 °C. China’s Refractories, 2006, 15(4):3-6.

|

| [14] |

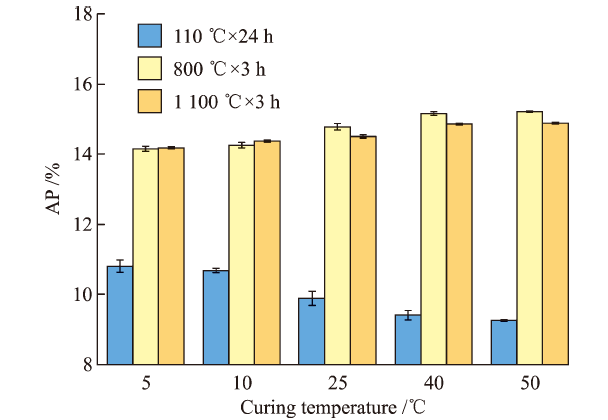

Ye Li, Lingling Zhu, Kun Liu, Dafei Ding, Ju Zhang, Guotian Ye. Effect of curing temperature on volume stability of CAC-bonded alumina-based castables. Ceramics International, 2019, 45(9):12066-12071.

DOI

|

| [15] |

Nicolas Schmitt, Jean-François Hernandez, Vincent Lamour, Yves Berthaud, Pierre Meunier, Jacques Poirier. Coupling between kinetics of dehydration, physical and mechanical behaviour for high alumina castable. Cement and Concrete Research, 2000, 30(10):1597-1607.

DOI

URL

|

| [16] |

Qingfeng Wang, Guotian Ye, Yajuan Wang, Anping Fu, Chuanyin Zhang, Xuejun Shang. Effect of micro-sized calcium carbonate addition on volumetric stability and strength of corundum-based castables. International Journal of Applied Ceramic Technology, 2015, 12(S2):E166-E171.

DOI

URL

|

)

)