| [1] |

Nitzl G., Seitz P., Tang Y. Energy saving monolithic ISO components for flow control and clean steel application. Proceedings of the 59th International Colloquium on Refractories, Aachen, Germany, 2016:210-213.

|

| [2] |

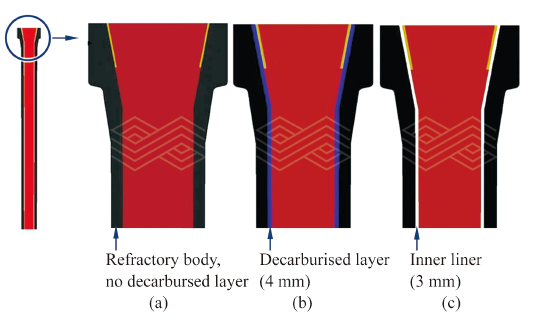

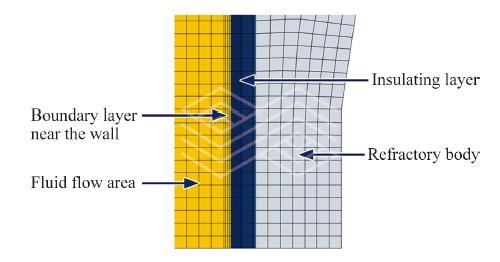

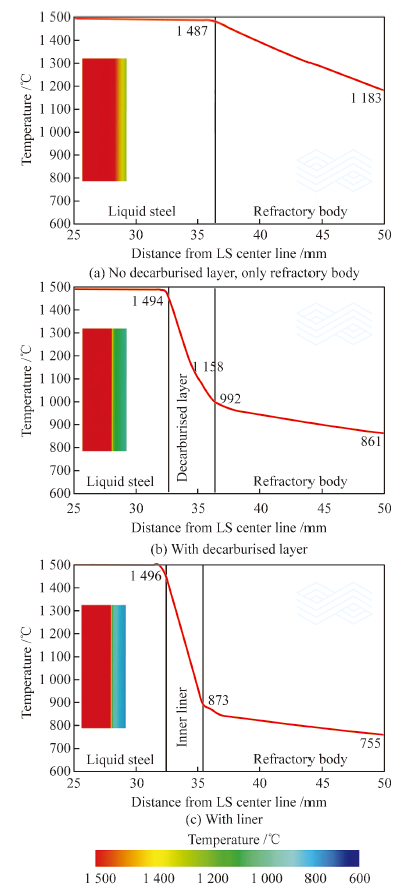

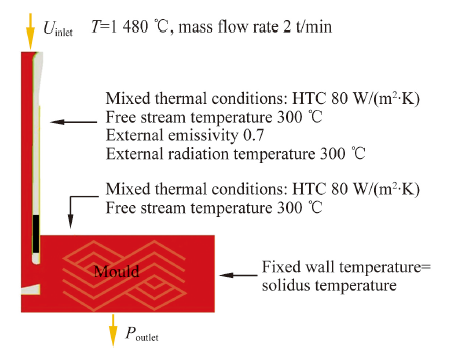

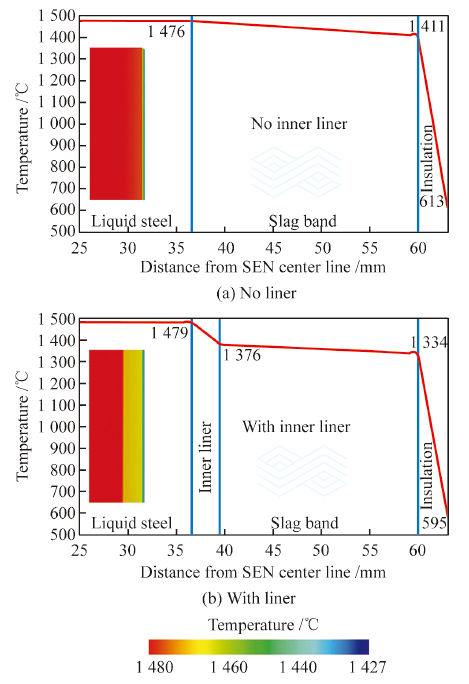

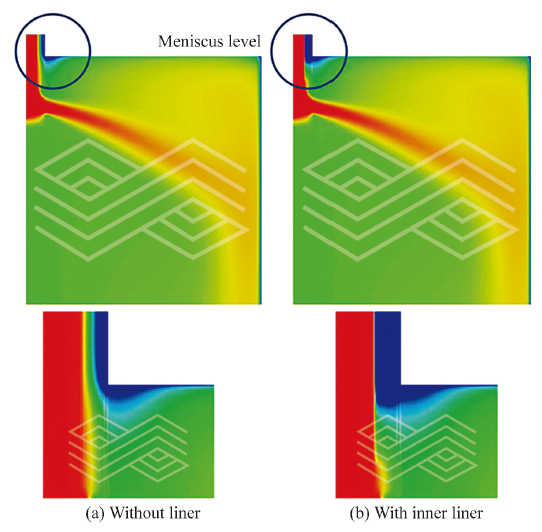

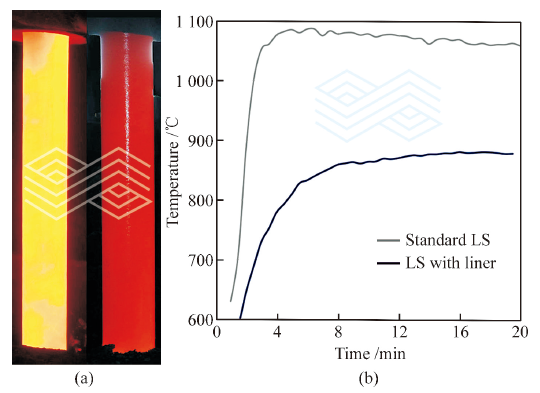

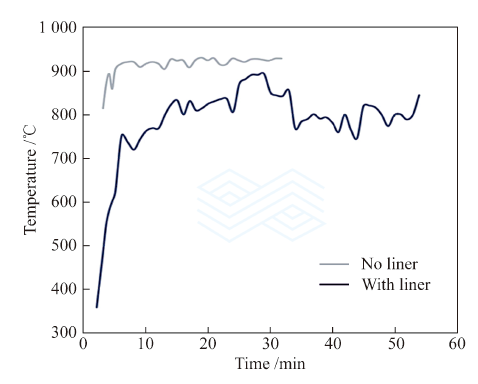

Tang Y., Hackl G., Nitzl G., Seitz P., Košir A. Simulation and industrial measurement of heat transfer of flow control products with special inner liner. Proceedings of STEELSIM, Qingdao, China, 2017.

|

| [3] |

Buhr A., Bruckhausen R., Fandrich R. Trends in clean steel technology and refractory engineering. Refractories Worldforum, 2016, 136:25-34.

|

| [4] |

Buhr A. Energy saving by modern raw material concepts. ALMATIS Kundenseminar Kaltenengers, 21 June 2016.

|

| [5] |

Akinari Sasaki, Katsumi Morikawa, Jyoki Yoshitomi. High durable nozzle for continuous casting. Proceedings of EUROGRESS, Aachen, Germany, 2010.

|

| [6] |

Franc Tehovnik, Jaka Burja, Boštjan Arh, Matjaz Knap. Submerged entry nozzle clogging during continuous casting of Al-killed steel. Metalurgija-Sisak then Zagreb, 2015, 54(2):371-374.

|

| [7] |

Svensson J. K. S., Memarpour A., Ekerot, S., Brabie, V., Jönsson, P. G. Studies of new coating materials to prevent clogging of submerged entry nozzle (SEN) during continuous casting of Al killed low carbon steels. Ironmaking and Steelmaking, 2017, 44(2):117-127.

DOI

URL

|

| [8] |

Dorrer P., Michelic S. K., Kloesch G., Reiter J., Paul A., Bernhard C. Study of clogging deposit build-up in Al-killed and Ca-treated high sulfur steels with focus on the steel/refractory interface. Proceddings of AISTech, 2017.

|

| [9] |

Dorrer P., Michelic S. K., Bernhard C., Penz A., Rössler R. Study on the influence of FeTi-addition on the inclusion population in Ti-stabilized ULC steels and its consequences for SEN-clogging. Steel Research International, 2019, 90(7):1800635.

DOI

URL

|

| [10] |

Chen Tian, Jingkun Yu, Endong Jin, Tianpeng Wen, Danbin Jia, Zhenli Liu, Paixian Fu, Lei Yuan. Effect of interfacial reaction behaviour on the clogging of SEN in the continuous casting of bearing steel containing rare earth elements. Journal of Alloys and Compounds, 2019, 792(5):1-7.

DOI

URL

|

), Yong TANG1, Gerald NITZL2

), Yong TANG1, Gerald NITZL2