| [1] |

Endong Jin, Jingkun Yu, Tianpeng Wen, Xinghui Hou, Beiyue Ma, Feixiong Mao. Fabrication of high-density magnesia using vacuum compaction molding. Ceramics International, 2018,44(6):6390-6394.

DOI

URL

|

| [2] |

Li Huan, Yu Jingkun, Kuang Shibo. Influence of light calcining hydration of magnesite on MgO sintering. China’s Refractories, 2009,18(3):23-28.

|

| [3] |

Liu Zhaoyang, Yu Jingkun, Yang Xin, Jin Endong, Yuan Lei. Oxidation resistance and wetting behavior of MgO-C refractories: effect of carbon content. Materials, 2018,11(6):883.

DOI

URL

|

| [4] |

Xu Xingwu, Rao Dongsheng. Influence of pseudomorph of magnesite on densification of MgO sintering. Journal of the Chinese Ceramic Society (in Chinese), 1988,16(3):244-251.

|

| [5] |

Li Nan. Formation, compressibility and sintering of aggregated MgO powder. Journal of Materials Science, 1989,24(2):485-492.

DOI

URL

|

| [6] |

Li Nan. Sintering mechanism and kinetic models of aggregated MgO powder compact. Journal of the Chinese Ceramic Society(in Chinese). 1994,22(1): 77-84.

|

| [7] |

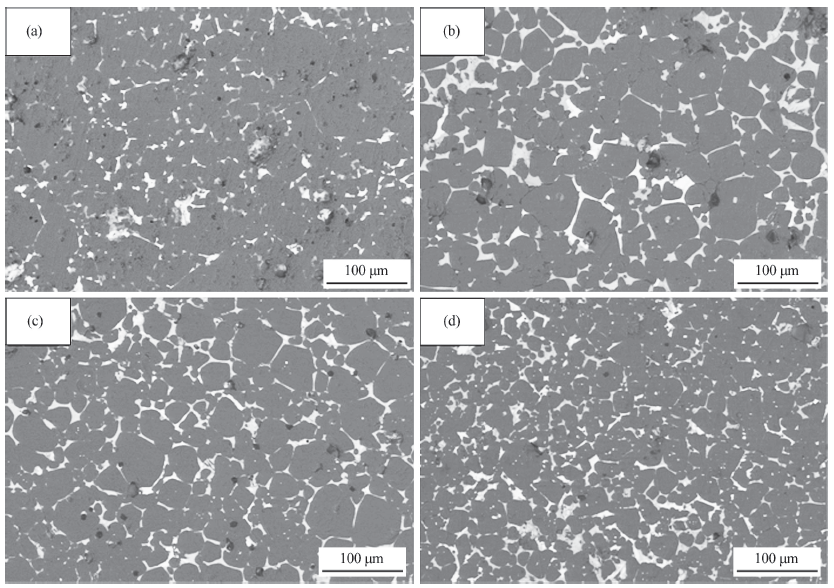

Jin Endong, Yu Jingkun, Wen Tianpeng, Tian Chen, Liu Zhaoyang, Ma Beiyue, Yuan Lei. Effect of the MgO aggregate size on the sintering densification of sintered MgO. Journal Ceramics-Silikáty, 2020,64(1):84-91.

|

| [8] |

Satyananda Behera, Ritwik Sarkar. Sintering of magnesia: effect of additives. Bulletin of Materials Science, 2015,38(6):1499-1505.

DOI

URL

|

| [9] |

Bingqiang Han, Yousheng Li, Chengcheng Guo, Nan Li, Fangyu Chen. Sintering of MgO-based refractories with added WO3. Ceramics International, 2007,33(8):1563-1567.

DOI

URL

|

| [10] |

Yang Qiuhong, Zeng Zhijiang, Xu Jun, Zhang Hongwei, Ding Jun. Effect of La2O3 on microstructure and transmittance of transparent alumina ceramics. Journal of Rare Earths, 2006,24(1):72-75.

DOI

URL

|

| [11] |

Tingting Wu, Jian Zhou, Bolin Wu, Wenjie Li. Effect of La2O3 content on wear resistance of alumina ceramics. Journal of Rare Earths, 2016,34(3):287-294.

|

| [12] |

Beiyue Ma, Ying Li, Shaogang Cui, Yuchun Zhai. Preparation and sintering properties of zirconia-mullite-corundum composites using fly ash and zircon. Transactions of the Nonferrous Metals Society of China, 2010,20(12):2331-2335.

DOI

URL

|

| [13] |

Jenqdaw Wang, Rishi Raj. Activation energy for the sintering of two-phase alumina/zirconia ceramics. Journal of the American Ceramic Society, 1991,74(8):1959-1963.

DOI

URL

|

)

)