China's Refractories ›› 2020, Vol. 29 ›› Issue (4): 1-5.DOI: 10.19691/j.cnki.1004-4493.2020.04.001

• Original article • Next Articles

Progress on Preparation and Characteristics of Ultra-lightweight Foam Concrete

ZHENG Juanrong1,*( ), ZHANG Simi1, ZHAO Zhenbo2

), ZHANG Simi1, ZHAO Zhenbo2

- 1 School of Civil Engineering, Zhengzhou University, Zhengzhou 450002, China

2 Zhengzhou Gongda New Building Material and High-Tech Co., Ltd., Zhengzhou 450002, China

-

Online:2020-12-15Published:2020-12-15 -

Contact:ZHENG Juanrong -

About author:Zheng Juanrong received her Ph.D. in the materials for civil engineering from Mining University of China (Beijing Campus) in 2011. After that she has been working as a professor in Civil Engineering School of Zhengzhou University. Her research focuses on the preparation and application of low-carbon cement-based materials and porous concrete.

Cite this article

ZHENG Juanrong, ZHANG Simi, ZHAO Zhenbo. Progress on Preparation and Characteristics of Ultra-lightweight Foam Concrete[J]. China's Refractories, 2020, 29(4): 1-5.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: http://www.cnref.cn/EN/10.19691/j.cnki.1004-4493.2020.04.001

| UFC-P | UFC-C | Foam concrete | Ordinary concrete | |

|---|---|---|---|---|

| Dry density /(kg · m-3) | 150-300 | 150-300 | 400-1 600 | 2 200-2 400 |

| Compressive strength /MPa | 0.5-1.5 | 0.5-1.1 | 0.5-10.0 | 30-80 |

| Flexural strength /MPa | - | - | 0.5-0.7 | 3.0-8.0 |

| Tensile strength /MPa | 0.10-0.13 | 0.10-0.13 | - | - |

| Modulus of elasticity /GPa | - | - | 0.3-1.2 | 20-30 |

| Dry shrinkage /×106 | ≤3000 | ≤3 000 | 1 500-3 500 | 600-900 |

| Thermal conductivity /(W · m-1 · K-1) | 0.045-0.068 | 0.050-0.071 | 0.11-0.3 | 1.63-1.74 |

| Freeze-thaw resistance /% | - | - | 90-97 | 90-97 |

| Fluidity of fresh slurry /mm | - | - | 200 | ~180 |

| Water absorption /% | ≤5 | ≤10 | - | - |

| Fire-resistance grade | A | A | - | - |

Table 1 Properties of UFC-C and UFC-P and foam concrete and ordinary concrete

| UFC-P | UFC-C | Foam concrete | Ordinary concrete | |

|---|---|---|---|---|

| Dry density /(kg · m-3) | 150-300 | 150-300 | 400-1 600 | 2 200-2 400 |

| Compressive strength /MPa | 0.5-1.5 | 0.5-1.1 | 0.5-10.0 | 30-80 |

| Flexural strength /MPa | - | - | 0.5-0.7 | 3.0-8.0 |

| Tensile strength /MPa | 0.10-0.13 | 0.10-0.13 | - | - |

| Modulus of elasticity /GPa | - | - | 0.3-1.2 | 20-30 |

| Dry shrinkage /×106 | ≤3000 | ≤3 000 | 1 500-3 500 | 600-900 |

| Thermal conductivity /(W · m-1 · K-1) | 0.045-0.068 | 0.050-0.071 | 0.11-0.3 | 1.63-1.74 |

| Freeze-thaw resistance /% | - | - | 90-97 | 90-97 |

| Fluidity of fresh slurry /mm | - | - | 200 | ~180 |

| Water absorption /% | ≤5 | ≤10 | - | - |

| Fire-resistance grade | A | A | - | - |

| For preparation of UFC-C[ | For preparation of UFC-P[ |

|---|---|

| Cement, slag, water, chemical and physical admixtures are mixed thoroughly | Cement, fly-ash, water, chemical admixtures are mixed thoroughly and ball milling for 30-60 minutes |

| Foaming agent is added and mixing quickly | Foam and physical admixtures are added and mixing quickly |

| Placing and Foaming (dimensions: 1.25 m×1.25 m×0.64 m) | Placing (dimensions: 1.25 m×1.25 m×0.64 m) |

| Rest and curing at room temperature | Rest and curing at 50-90 ℃ |

| Demoulding | Demoulding |

| Products by cutting (dimensions: 600 mm×300 mm×(30-80) mm) | Products by cutting (dimensions: 600 mm×300 mm×(30-80) mm) |

Table 2 Preparation processes of UFC-C and UFC-P

| For preparation of UFC-C[ | For preparation of UFC-P[ |

|---|---|

| Cement, slag, water, chemical and physical admixtures are mixed thoroughly | Cement, fly-ash, water, chemical admixtures are mixed thoroughly and ball milling for 30-60 minutes |

| Foaming agent is added and mixing quickly | Foam and physical admixtures are added and mixing quickly |

| Placing and Foaming (dimensions: 1.25 m×1.25 m×0.64 m) | Placing (dimensions: 1.25 m×1.25 m×0.64 m) |

| Rest and curing at room temperature | Rest and curing at 50-90 ℃ |

| Demoulding | Demoulding |

| Products by cutting (dimensions: 600 mm×300 mm×(30-80) mm) | Products by cutting (dimensions: 600 mm×300 mm×(30-80) mm) |

| Dry density /(kg · m-3) | Porosity /% | Pore size distribution /% | Connected pore volume /% | |||

|---|---|---|---|---|---|---|

| 1.0-4.0 mm | 0.05-0.1 mm | |||||

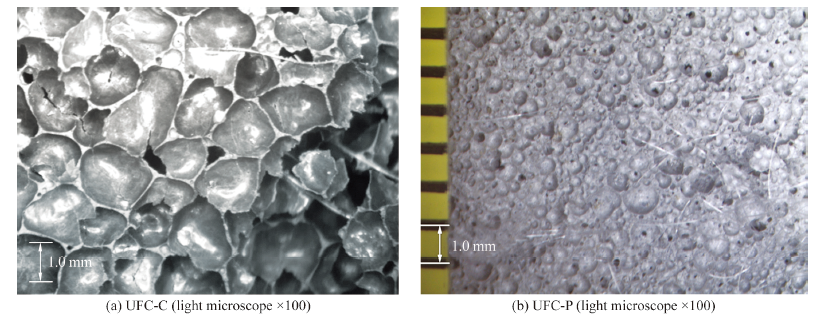

| UFC-C | UFC-P | UFC-C | UFC-P | UFC-C | UFC-P | |

| 150 | 78 | 76 | 85 | 90 | 8.5 | 4 |

| 200 | 75 | 73 | 90 | 92 | 7.8 | 3 |

| 250 | 74 | 70 | 95 | 95 | 7.5 | 2 |

| 300 | 70 | 65 | 90 | 100 | 7.0 | 0 |

Table 3 Characteristics of air-voids structures of UFC-C and UFC-P with different dry densities[12]

| Dry density /(kg · m-3) | Porosity /% | Pore size distribution /% | Connected pore volume /% | |||

|---|---|---|---|---|---|---|

| 1.0-4.0 mm | 0.05-0.1 mm | |||||

| UFC-C | UFC-P | UFC-C | UFC-P | UFC-C | UFC-P | |

| 150 | 78 | 76 | 85 | 90 | 8.5 | 4 |

| 200 | 75 | 73 | 90 | 92 | 7.8 | 3 |

| 250 | 74 | 70 | 95 | 95 | 7.5 | 2 |

| 300 | 70 | 65 | 90 | 100 | 7.0 | 0 |

| [1] | R. C. Valore. Cellular concrete part 1 composition and methods of production. ACI J., 1954, 50: 773-796. |

| [2] | R. C. Valore. Cellular concrete part 2 physical properties. ACI J., 1954, 50: 817-836. |

| [3] |

M. R. Jones, A. McCarthy. Preliminary views on the potential of foamed concrete as a structural material. Magazine of Concrete Research, 2005, 57(1): 21-31.

DOI URL |

| [4] | K. Ramamurthy, E. K. Kunhanandan Nambiar, G. Indu Siva Ranjani. A classification of studies on properties of foam concrete. Cement & Concrete Composites, 2009, 31: 388-396. |

| [5] | Amritha Raj, Dhanya Sathyan, K M Mini. Physical and functional characteristics of foam concrete: A review. Construction and Building Materials, 2019, 221: 787-799. |

| [6] | Gu Yancheng, Chen Sinuo, Huang Enxing. Present situation and development of building energy-saving insulation materials. Building Energy Efficiency (in Chinese), 2016, 44(6): 34-38. |

| [7] | Kong Xiangfei, Liu Shaoning, Zhong Yuliang, Rong Xian, Yang Hua, Qi Chengying. Analysis and optimization of multi-factor heat characteristics of phase change storage wall. Building Science (in Chinese), 2016, 32(8): 40-46. |

| [8] | Recommended technical regulations for construction of Jiangsu Province, Technical specification for external thermal insulation systems of composite foam cement panel (JG/T 041-2011), Published by Department of Housing and Urban-rural Development of Jiangsu Province (in Chinese), 2011-03-01. |

| [9] | Construction standards of Chongqing City, Technical specification for application of modified foam cement insulation board thermal insulation system on building (DBJ 50/T-185-2014), Published by Department of Housing and Urban-rural Development of Chongqing City (in Chinese), 2014-04-03. |

| [10] | Construction standards of Henan Province, Technical specification for the application of inorganic plasticized micro-porous insulation board (DBJ 41/T 200-2018), Published by Department of Housing and Urban-rural Development of Henan Province (in Chinese), 2018-09-03. |

| [11] | Huang Zhengyu, Sun Qingfeng, Zhou Zhimin. Study on pore structure and properties of super-lightweight foam concrete with OPC-SAC mixture. Bulletin of the Chinese Ceramic Society (in Chinese), 2013, 32(9): 1894-1899. |

| [12] | Zhaoming Huang, Tongsheng Zhang, Ziyun Wen. Proportioning and characterization of Portland cement-based ultra-lightweight foam concretes. Construction and Building Materials, 2015, 79: 390-396. |

| [13] | Wu Jiandong, Zhang Zerui, Zhang Yi, Li Dongxu. Preparation and characterization of ultra-lightweight foamed geopolymer (UFG) based on fly ash-metakaolin blends. Construction and Building Materials, 2018, 168: 771-779. |

| [14] | Lv Qingang, Pan Zhihua, Li Hengzhi. Effect of ultrafine slag powder on preparation and performance of foamed concrete. New Building Materials (in Chinese), 2013, (3): 56-58. |

| [15] | Zhao Zhenbo, Zheng Juanrong, Zhang Linlin, Li Haiyu, Xiong Jinxiu. Preparation and properties of inorganic plasticized microporous thermal insulation board. New Building Materials (in Chinese), 2019, (3): 148-150+154. |

| [16] | Zhang Xu, Wang Wuxiang, Yang Dingyi, Zhang Leilei. Study on control measures of pore structure of ultra lightweight foam concrete. Bulletin of the Chinese Ceramic Society (in Chinese), 2019, 38(7): 2255-2267. |

| [17] | Li Hengzhi, Pan Zhihua. Investigation on the improvement of water resistance property of the super low density foam concrete. Concrete (in Chinese), 2014, 296(6): 88-91. |

| [18] | Pan Zhihua, Li Hengzhi, Liu Wenqing. Preparation and chara-cterization of super low density foamed concrete from Portland cement and admixtures. Construction and Building Materials, 2014, 72(15): 256-261. |

| [19] | Xu Wen, Qian Guanlong, Hua Zilong. Experimental study on the preparation of foam concrete by chemical method. China Concrete and Cement Products (in Chinese), 2011, (12): 1-4. |

| [20] | E. K. Kunhanandan Nambiar, K. Ramamurthy. Influence of filler type on the properties of foam concrete. Cement and Concrete Composites, 2006, 28(5): 475-480. |

| [21] | E. K. Kunhanandan Nambiar, K. Ramamurthy. Models relating mixture composition to the density and strength of foam concrete using response surface methodology. Cement and Concrete Composites, 2006, 28(9): 752-760. |

| [22] | E. K. Kunhanandan Nambiar, K. Ramamurthy. Air-void characterisation of foam concrete. Cement and Concrete Research, 2007, 37(2): 221-230. |

| [23] | E. P. Kearsley, P. J. Wainwright. Porosity and permeability of foamed concrete. Cement and Concrete Research, 2001, 31(5): 805-812. |

| [24] | Wu Zhiju, Yan Qiuhui, Luo Jieren. Experimental study on improving the thermal insulation performance of rock wool by silica aerogel. Building Energy & Environment (in Chinese), 2019, 38(5): 13-16. |

| [25] | Classification for burning behavior of building materials and products (GB 8624-2012), Published by China National Standardization Administration Committee, 2012-12-31. |

| [1] | HU Chen, WANG Xing, LIU Zhenglong, DING Jun, YU Chao, DENG Chengji. Effect of ZrC Modified Graphite on Structure and Properties of Low-carbon Al2O3-C Refractories [J]. China's Refractories, 2024, 33(1): 18-22. |

| [2] | CHEN Yang, DENG Chengji, DING Jun, YU Chao, LOU Xiaoming. Effect of Ferric Nitrate Loading Mode on Properties of Si3N4 Composite MgO-C Refractories Prepared by Nitridation [J]. China's Refractories, 2023, 32(3): 6-9. |

| [3] | GAO Qianyu, WU Aijun, WANG Qi, YIN Hongji. Zirconia Hollow Spheres and Their Application [J]. , 2018, 27(4): 26-30. |

| [4] | WANG Fucheng, WEI Guoping, LUO Ming, FANG Binxiang. Effects of Resins with Different Molecular Structures on Properties of MgO-C Bricks [J]. , 2017, 26(4): 31-36. |

| [5] | YU Renhong, LIU Pengcheng, DONG Gaofeng, DONG Hongqin. Effects of Spherical Light-weight Aggregates Additions on Workability and Mechanical Properties of Al2O3-SiO2 System Castables [J]. , 2017, 26(4): 1-6. |

| [6] | Ali Baghaei, Mehdi Naeemi. Impact of Functional Additives on Properties of Al2O3–C Slide Gate Plate Refractories [J]. , 2017, 26(3): 19-22. |

| [7] | YU Renhong1, LIU Pengcheng1, ZHOU Xiwen1, ZHOU Ningsheng1, YANG Dahui1, DONG Gaofeng2. Effects of Spherical Aggregates Addition on Properties of Al2O3-SiO2 System Castables [J]. , 2017, 26(1): 13-17. |

| [8] | Sergey M. LOGVINKOV*,Galina N. SHABANOVA,Alla N. KOROHODSKA, Elena V. KHRYSTYCH. Modified Alumina Cement with High Service Properties [J]. , 2016, 25(4): 1-5. |

| [9] | GAO Jianying, ZHANG Ziying, BRUNO Touzo. Thermo-mechanical Properties of In-situ Formed Al2O3-SiC-SiAlON Composites [J]. , 2016, 25(2): 1-6. |

| [10] | LIAO Ning, LIYawei,SANG Shaobai, CHEN Songlin, ZENG Luju. Effect of Nano Carbon Black and Graphite Flake on Properties of Low Carbon Al2O3-C Refractories [J]. , 2016, 25(2): 17-24. |

| [11] | HUANG Yalei,GUQiang,WENYubin, LIU Zhifang, LIU Xinhong. Thermo-mechanical Properties of In-situ Formed Al2O3-SiC-SiAlON Composites [J]. , 2016, 25(2): 48-52. |

| [12] | WANG Yujin*,WEI Boxin,CHEN Lei, OUYANG Jiahu, ZHOU Yu. Research Progress on Preparation and Properties of Zirconium Carbide Matrix Composites [J]. , 2015, 24(3): 1-11. |

| [13] | YUAN Bo*,CHEN Kuo,HAN Jianshen, DONG Binbin, WANG Gang, LI Hongxia. Thermal Insulation Materials of Alumina Based Porous Ceramics [J]. , 2015, 24(3): 29-33. |

| [14] | LIN Sen*,YAO Dongxu,XIA Yongfeng, ZUO Kaihui, YIN Jinwei, ZENG Yuping. Influence of Yb2O3-MgO on Mechanical Properties and Thermal Conductivity of Silicon Nitride Ceramics via Gas Pressure Sintering [J]. , 2015, 24(3): 34-39. |

| [15] | REN Zhen, GE Tiezhu, ZHONG Xiangchong. Effects of Al-Si Addition on Thermomechanical Properties of Low-carbon MgO-C Materials [J]. , 2013, 22(2): 11-14. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||