China's Refractories ›› 2020, Vol. 29 ›› Issue (2): 42-46.DOI: 10.19691/j.cnki.1004-4493.2020.02.008

• Original article • Previous Articles

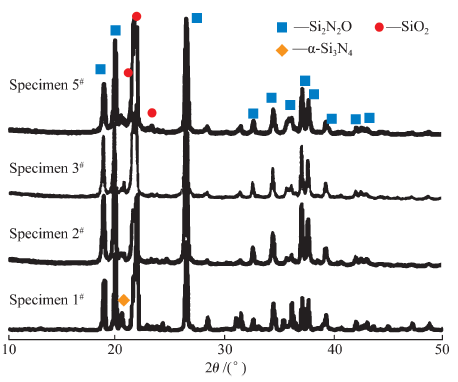

Preparation and Properties of Si2N2O Ceramics for Microwave Sintering Furnaces

ZHENG Han1, LI Wei2, DU Jiaolong2, LI Hongxia1, LIU Guoqi1, CHEN Zihao1, CHEN Yongqiang1,2

- 1 Sinosteel Luoyang Institute of Refractories Research Co., Ltd., Luoyang 471039, China

2 School of Materials Science and Engineering, Zhengzhou University, Zhengzhou 450001, China